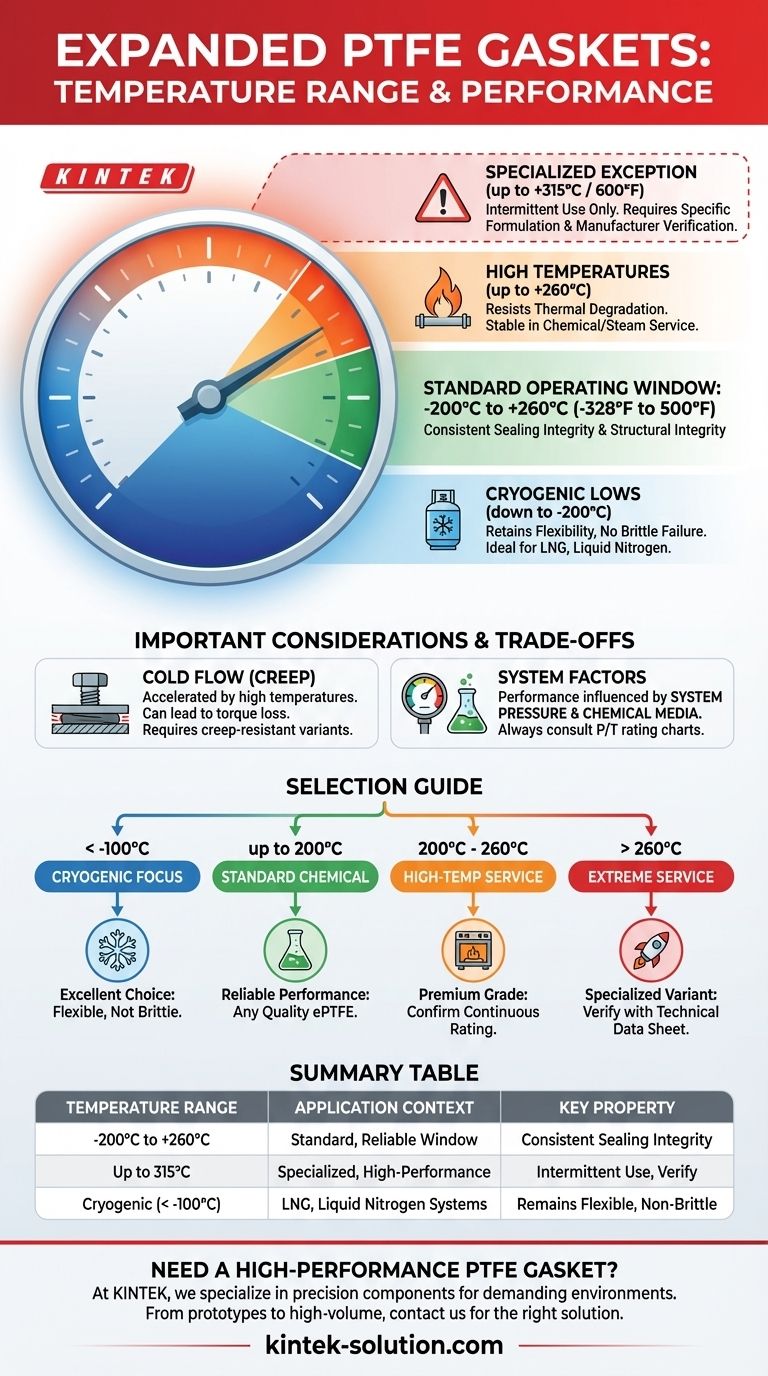

The operational temperature range for expanded PTFE gaskets is exceptionally wide, reliably spanning from cryogenic lows of -200°C (-328°F) up to continuous service highs of 260°C (500°F). While some specialized formulations can tolerate intermittent spikes up to 315°C (600°F), the 260°C threshold is the most dependable benchmark for standard industrial applications.

The true value of expanded PTFE is not just its high temperature ceiling, but its remarkable consistency and structural integrity across this entire spectrum. However, understanding that this rating is influenced by system pressure and the specific gasket formulation is critical for ensuring a reliable, long-term seal.

Why This Temperature Range Matters

The ability of a gasket to function from cryogenic temperatures to high-heat processing is what makes expanded PTFE (ePTFE) a cornerstone material in demanding industries. Its performance is rooted in the inherent stability of its molecular structure.

Performance at Cryogenic Lows

Unlike many elastomers that become hard and brittle at extreme lows, expanded PTFE retains a degree of flexibility and resilience down to -200°C (-328°F). This makes it a premier choice for applications involving liquefied gases like LNG or liquid nitrogen.

Stability at High Temperatures

At the upper end of its range, ePTFE resists thermal degradation. It does not melt but maintains its solid form, ensuring a consistent and stable sealing effect even in applications like chemical processing or steam service.

Understanding the Temperature Limits

While the numbers provide a clear guideline, the context behind them is essential for proper material selection. The published temperature range refers to the material's ability to maintain its critical sealing properties.

The Standard Operating Window: -200°C to +260°C

This is the most widely accepted and safest operational range for the vast majority of high-quality ePTFE gaskets. Within this window, the material provides predictable performance and a long service life.

The High-Performance Exception: Reaching 315°C

Certain premium, specialized grades of expanded PTFE can handle temperatures up to 315°C (600°F). This capability is not standard and should never be assumed. It is reserved for specific formulations designed for the most extreme applications.

Factors Beyond Temperature

A gasket's performance is a function of the entire system. The maximum allowable temperature is often dependent on system pressure and the chemical media being sealed. Always consult the manufacturer's P/T rating chart, which shows the relationship between acceptable pressures and temperatures.

Key Trade-offs and Pitfalls to Avoid

No material is perfect. The unique properties of PTFE introduce specific considerations that must be managed, particularly when operating near its temperature limits.

The Risk of Cold Flow (Creep)

PTFE's most well-known limitation is its tendency to creep, or "cold flow," under compressive load. This effect is accelerated by high temperatures. Over time, this can lead to a loss of bolt torque and a potential reduction in sealing pressure.

Mismatching the Gasket to the Application

Using a general-purpose ePTFE gasket in an application that requires a high-temperature, creep-resistant variant is a common cause of premature failure. The cost difference is minimal compared to the cost of a leak.

Ignoring Manufacturer Specifications

The term "expanded PTFE" covers a wide range of products with different densities, structures, and sometimes fillers. Relying on a generic temperature rating instead of the specific technical data sheet for your chosen gasket is a significant risk.

Making the Right Choice for Your Application

Use your intended service conditions as the primary guide for selecting the right gasket.

- If your primary focus is cryogenic service (below -100°C): Expanded PTFE is an excellent choice due to its ability to remain flexible without becoming brittle.

- If your primary focus is standard chemical processing (up to 200°C): Any high-quality ePTFE gasket will perform reliably well within this conservative range.

- If your primary focus is high-temperature service (200°C to 260°C): Select a premium-grade gasket from a reputable manufacturer and confirm its continuous service temperature rating.

- If your application requires service above 260°C: You must source a specialized, high-temperature variant and verify its suitability for your exact pressure and media conditions via its technical data sheet.

Ultimately, treating the manufacturer's data sheet as the definitive source of truth is the key to ensuring a safe and reliable seal.

Summary Table:

| Temperature Range | Application Context | Key Property |

|---|---|---|

| -200°C to +260°C | Standard, reliable operating window | Consistent sealing integrity |

| Up to 315°C | Specialized, high-performance grades | Intermittent use only; verify with manufacturer |

| Cryogenic (< -100°C) | LNG, liquid nitrogen systems | Remains flexible, does not become brittle |

Need a high-performance PTFE gasket that can handle your extreme temperatures?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals and gaskets, for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors. Whether you require a standard solution for cryogenic service or a custom-fabricated, high-temperature variant, our expertise ensures a reliable, long-term seal.

Contact us today to discuss your specific temperature, pressure, and chemical media requirements. Let our team provide you with the right PTFE solution, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Deep Evaporating Dishes Customizable Laboratory and Industrial Solutions

People Also Ask

- Why is PTFE considered a safe choice for O-ring seals? Ensure Reliability in Extreme Conditions

- What are the key properties of PTFE that benefit bellows and diaphragms? Achieve Unmatched Reliability in Harsh Environments

- What are the operating conditions where PTFE slide bearings perform best? Optimize for High Load & Low Speed

- What types of gasket materials are available besides PTFE? Find the Perfect Seal for Your Application

- What maintenance advantages do PTFE compensators offer? Maximize Uptime with Self-Cleaning Design

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What factors should be considered when choosing a PTFE sheet? Select the Right Grade for Your Application

- What are the main disadvantages of machining Teflon/PTFE? Navigating Material Instability for Precision Parts