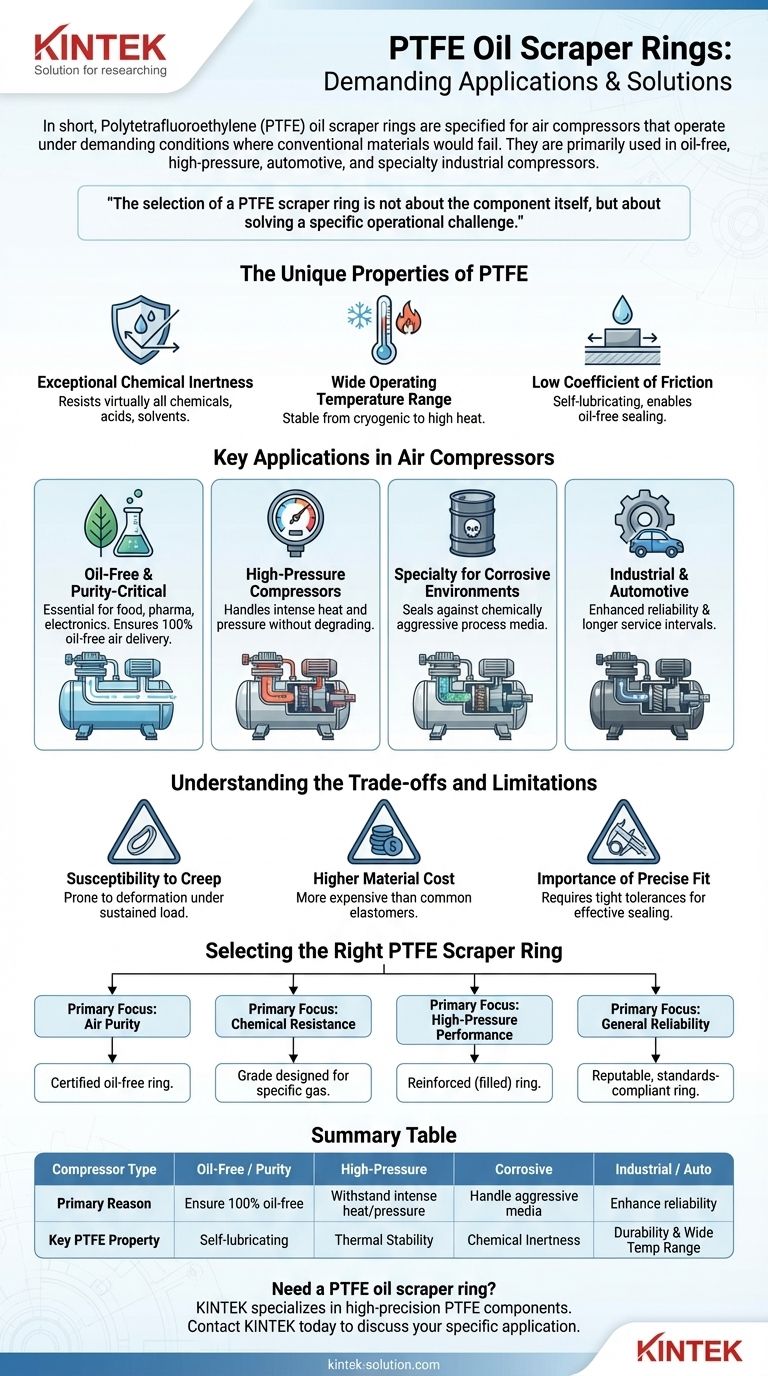

In short, Polytetrafluoroethylene (PTFE) oil scraper rings are specified for air compressors that operate under demanding conditions where conventional materials would fail. They are primarily used in oil-free, high-pressure, automotive, and specialty industrial compressors that handle corrosive gases or require exceptional purity.

The selection of a PTFE scraper ring is not about the component itself, but about solving a specific operational challenge. PTFE is chosen for its unique ability to withstand extreme temperatures, aggressive chemicals, and the need for oil-free operation, making it a problem-solver for critical applications.

The Unique Properties of PTFE

Before looking at specific compressors, it's essential to understand why PTFE is the material of choice. Its value comes from a unique combination of properties that are difficult to find in other materials.

Exceptional Chemical Inertness

PTFE is virtually inert and does not react with most chemicals, acids, or solvents. This makes it ideal for systems that compress or are exposed to corrosive substances.

Wide Operating Temperature Range

The material maintains its integrity and performance across an exceptionally broad temperature spectrum. It remains stable in high-temperature applications like jet engines and does not become brittle at the extremely low temperatures found in aerospace uses.

Low Coefficient of Friction

PTFE is one of the most slippery materials known, giving it a very low coefficient of friction. This self-lubricating property is critical for creating an effective seal in "oil-free" systems where no external lubricant can be introduced.

Key Applications in Air Compressors

The unique characteristics of PTFE directly map to its use in specific types of air compressors where performance and reliability are non-negotiable.

Oil-Free and Purity-Critical Compressors

These compressors are essential in industries like food and beverage, pharmaceuticals, and electronics manufacturing, where even trace amounts of oil contamination are unacceptable. The self-lubricating nature of PTFE rings allows them to effectively scrape moisture without requiring oil, ensuring 100% oil-free air delivery.

High-Pressure Compressors

In the energy and petrochemical industries, compressors often operate at very high pressures, which generates significant heat. PTFE's thermal stability ensures the scraper rings do not degrade, melt, or lose their sealing capability under these intense conditions.

Specialty Compressors for Corrosive Environments

Chemical plants and processing facilities frequently compress gases that are chemically aggressive. PTFE's chemical inertness is the critical factor here, as the scraper rings can maintain a seal without being corroded or damaged by the process media.

Industrial and Automotive Compressors

While it may seem like overkill for general use, PTFE is often specified in robust industrial plant air systems and automotive applications (like air brakes and A/C). Its durability and wide operating tolerances contribute to longer service intervals and enhanced reliability in environments with fluctuating demands.

Understanding the Trade-offs and Limitations

While highly effective, PTFE is not a universal solution. An objective evaluation requires acknowledging its trade-offs.

Susceptibility to Creep

PTFE is a polymer, not a metal. Under sustained pressure and temperature, it can be prone to "creep," or slow deformation over time. This makes proper engineering and pairing with support components essential, especially in high-pressure applications.

Higher Material Cost

As a high-performance specialty polymer, PTFE is inherently more expensive than common sealing materials like nitrile or other elastomers. Its use is justified when the cost of failure or contamination is significantly higher than the component cost.

Importance of Precise Fit

The performance of a PTFE ring is highly dependent on precise dimensions and a proper fit within the piston and cylinder. Unlike more forgiving elastomers, an improperly sized PTFE ring can fail to seal effectively, making manufacturing and installation tolerances critical.

Selecting the Right PTFE Scraper Ring

Your final choice should be guided by your specific operational goal. Match the ring's specifications to the demands of the application.

- If your primary focus is air purity: Select a ring specifically certified for oil-free operation, often used in food, medical, or pharmaceutical-grade compressors.

- If your primary focus is chemical resistance: Ensure the PTFE grade is designed for the specific chemical and temperature profile of your process gas.

- If your primary focus is high-pressure performance: Choose a ring, possibly filled with carbon or bronze, that is engineered to resist deformation and wear under high thermal and mechanical loads.

- If your primary focus is general reliability: Opt for rings from reputable manufacturers that meet established industry standards to ensure consistent durability and lifespan.

Ultimately, choosing the right scraper ring is about aligning the material's properties with the precise demands of your compressor's operating environment.

Summary Table:

| Compressor Type | Primary Reason for PTFE Use | Key PTFE Property Utilized |

|---|---|---|

| Oil-Free / Purity-Critical | Ensure 100% oil-free air delivery | Self-lubricating (Low friction) |

| High-Pressure | Withstand intense heat and pressure | Thermal Stability |

| Corrosive Gas / Chemical | Handle aggressive process media | Chemical Inertness |

| Industrial / Automotive | Enhance reliability and service life | Durability & Wide Temperature Range |

Need a PTFE oil scraper ring that matches your compressor's demands?

KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your compressor operates reliably under the most demanding conditions.

Contact KINTEK today to discuss your specific application and receive a tailored solution that guarantees performance and purity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Scrapers and Shovels for Demanding Applications

People Also Ask

- What are PTFE expansion joints and their primary function? Protect Piping Systems from Stress and Corrosion

- How does the PTFE seat butterfly valve achieve corrosion resistance? Total Isolation from Corrosive Media

- What is the function of a teflon check valve in control systems? Prevent Backflow in Corrosive & High-Temp Processes

- What are the main industries that use PTFE lip seals? Solve Extreme Sealing Challenges

- What are the key features of PTFE gaskets? Unlock Superior Chemical & Thermal Sealing

- What future trends are expected in Teflon parts machining? AI, Automation, and Sustainability

- In which industries or applications are PTFE O-rings typically used? Solve Extreme Sealing Challenges

- What are common industrial applications of machined Teflon parts? Solve Friction, Chemical & Electrical Challenges