In the coming years, the machining of Teflon parts will be defined by a convergence of smart manufacturing, advanced automation, and a strong push toward sustainability. These trends are not merely incremental improvements but a strategic response to the material's inherent challenges, leveraging technologies like AI and the Internet of Things (IoT) to elevate precision, efficiency, and quality control.

The future of Teflon machining isn't about replacing core techniques but augmenting them with digital intelligence. The goal is to use data-driven optimization and automation to finally master the material's most difficult properties, such as thermal expansion and softness.

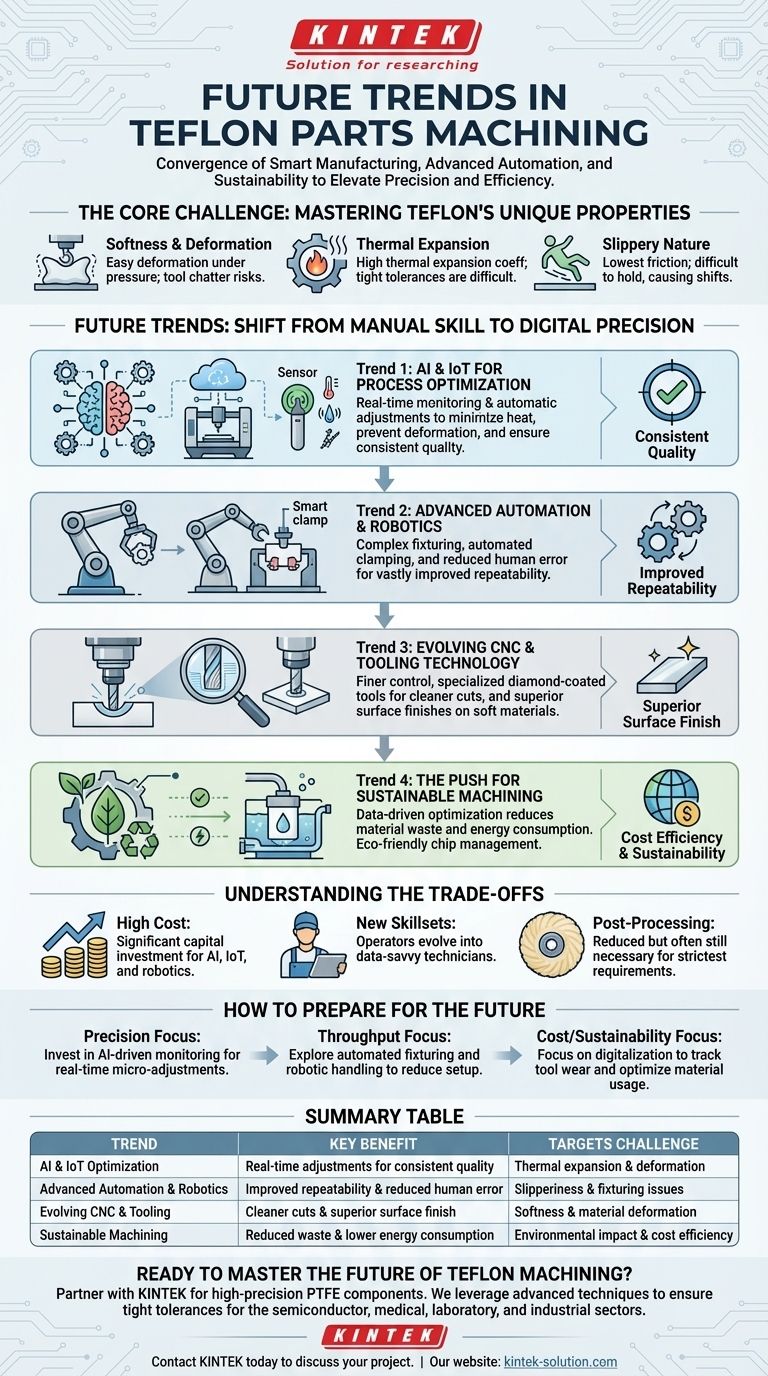

The Core Challenge: Mastering Teflon's Unique Properties

Before looking at future trends, we must acknowledge the fundamental problems they aim to solve. Teflon (PTFE) is notoriously difficult to machine with high precision due to its unique physical characteristics.

The Problem of Softness and Deformation

Teflon is a very soft material. This softness means it can easily deform under the pressure of clamps or cutting tools, leading to dimensional inaccuracies and potential tool chatter.

The Fight Against Thermal Expansion

Teflon has a very high coefficient of thermal expansion. Even minor heat generated during machining can cause the part to expand significantly, making it incredibly difficult to hold tight tolerances.

The Slippery Nature of the Material

With one of the lowest coefficients of friction of any solid, Teflon is difficult to hold securely. This slipperiness complicates fixturing and can cause the workpiece to shift during machining, compromising precision and surface finish.

Future Trends: The Shift from Manual Skill to Digital Precision

The next wave of innovation directly targets these long-standing challenges by embedding intelligence and consistency into every step of the process.

Trend 1: AI and IoT for Process Optimization

Smart sensors (IoT) will be embedded in machines to monitor variables like temperature, vibration, and tool wear in real-time.

Artificial intelligence (AI) will analyze this data to automatically adjust cutting speeds, feed rates, and coolant flow. This real-time optimization will minimize heat generation and prevent part deformation, ensuring consistent quality.

Trend 2: Advanced Automation and Robotics

Robotics will move beyond simple part loading and unloading. Future systems will handle complex fixturing, automatically adjusting clamping pressure based on the specific part geometry to avoid distortion.

This level of automation ensures every part is held and machined under identical conditions, drastically improving repeatability and reducing human error.

Trend 3: Evolving CNC and Tooling Technology

As CNC technology continues to advance, machines will offer finer control over tool paths and spindle speeds, enabling more delicate cuts that generate less heat.

Furthermore, the use of specialized tooling, such as diamond-coated cutters, will become more widespread. These tools maintain a sharp edge longer, producing cleaner cuts and superior surface finishes on soft materials like Teflon.

Trend 4: The Push for Sustainable Machining

Digitalization enables a more sustainable process. By precisely optimizing cutting parameters, manufacturers can reduce material waste and energy consumption per part.

Improved chip management and coolant filtration systems will also become standard, minimizing the environmental impact of the machining operation.

Understanding the Trade-offs

Adopting these advanced technologies requires a clear understanding of their associated challenges and costs.

The High Cost of Implementation

Integrating AI, IoT sensors, and advanced robotics is a significant capital investment. The initial cost can be a barrier for smaller machine shops.

The Need for New Skillsets

The role of the machine operator will evolve. Instead of relying solely on manual skill, operators will need to become technicians capable of managing and interpreting data from these smart systems.

Post-Processing Remains a Factor

Even with advanced machining, some level of post-processing, like deburring or polishing, will often be necessary to meet the most stringent surface finish and accuracy requirements. Technology reduces this need but may not eliminate it entirely.

How to Prepare for the Future of Teflon Machining

Your strategy for adopting these trends should align directly with your primary business goals.

- If your primary focus is maximizing precision: Investigate AI-driven monitoring systems that can make micro-adjustments in real-time to counteract thermal expansion.

- If your primary focus is increasing throughput: Explore automated fixturing and robotic handling to reduce setup times and ensure operational consistency.

- If your primary focus is reducing operational costs: Focus on digitalization to track tool wear and optimize material usage, which provides a direct path to greater sustainability and efficiency.

Ultimately, harnessing these future trends will transform Teflon's notorious machining challenges into a controllable, data-driven science.

Summary Table:

| Trend | Key Benefit | Targets Challenge |

|---|---|---|

| AI & IoT Optimization | Real-time adjustments for consistent quality | Thermal expansion & deformation |

| Advanced Automation & Robotics | Improved repeatability & reduced human error | Slipperiness & fixturing issues |

| Evolving CNC & Tooling | Cleaner cuts & superior surface finish | Softness & material deformation |

| Sustainable Machining | Reduced waste & lower energy consumption | Environmental impact & cost efficiency |

Ready to Master the Future of Teflon Machining?

As these trends redefine precision manufacturing, partnering with an expert becomes critical. KINTEK specializes in machining high-precision PTFE components for the semiconductor, medical, laboratory, and industrial sectors. We leverage advanced techniques to overcome Teflon's unique challenges, ensuring your parts meet the tightest tolerances.

Our capabilities range from custom prototypes to high-volume production, all backed by a commitment to quality and efficiency. Let us help you turn these future trends into your competitive advantage.

Contact KINTEK today to discuss your project and discover how our expertise can benefit you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers