In short, PTFE lip seals are essential wherever standard seals fail. Their unique properties make them indispensable in demanding sectors such as Aerospace, Oil & Gas, Chemical Processing, and Food & Pharmaceuticals. They are also heavily utilized in automotive, construction machinery, and specialized medical applications that push the limits of material science.

The specific industry is less important than the operating conditions it presents. PTFE lip seals are chosen not for the industry itself, but for the extreme challenges—high speeds, aggressive chemicals, or wide temperature ranges—where conventional elastomer seals would quickly degrade and fail.

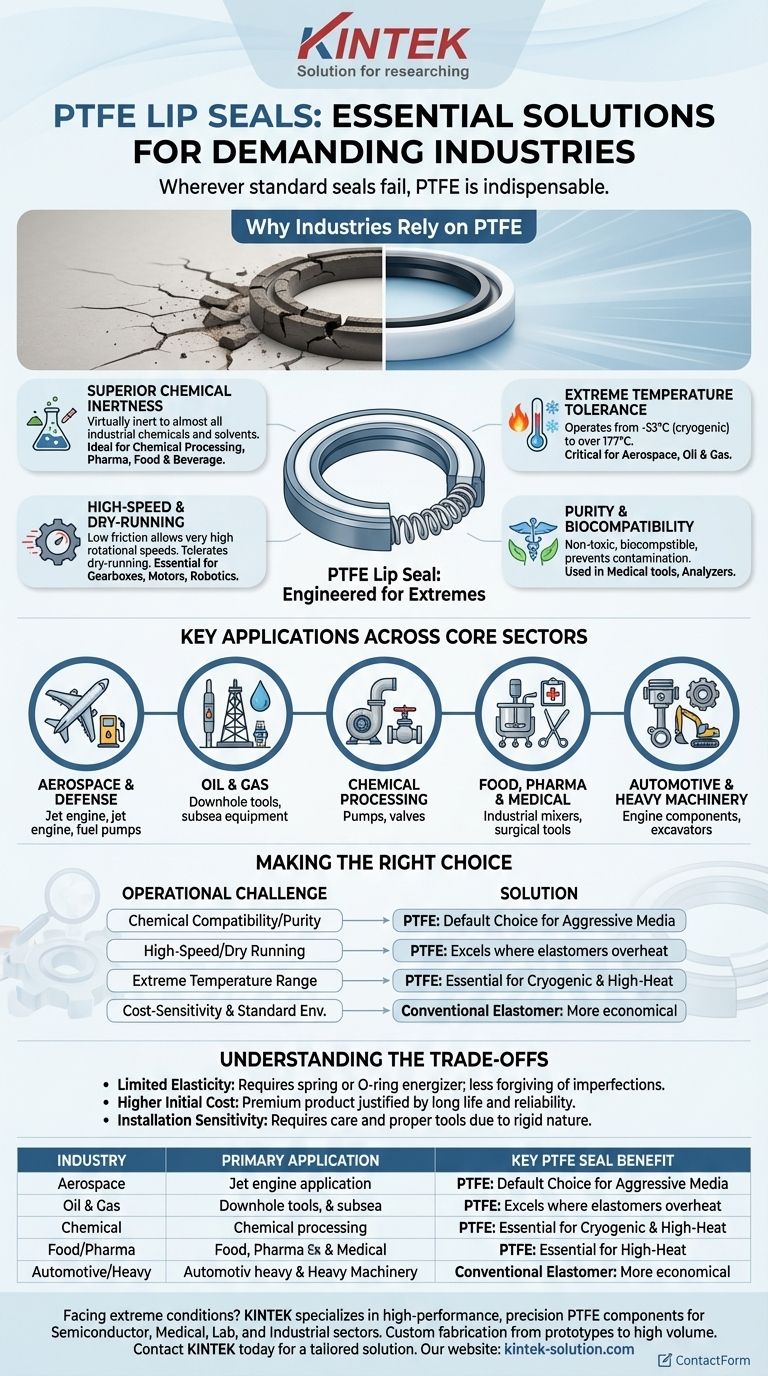

Why Industries Rely on PTFE Lip Seals

The widespread adoption of PTFE seals is a direct result of the material's fundamental properties. Unlike traditional rubber or elastomer seals, PTFE offers a combination of resistances that makes it the only viable choice for many critical applications.

Superior Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it a default choice in the chemical processing industry for pumps, valves, and mixers handling corrosive substances.

This same property is vital in the pharmaceutical and food & beverage sectors, where the seal must not react with or contaminate the product.

Extreme Temperature Tolerance

PTFE seals operate effectively across a vast temperature spectrum, from cryogenic applications (-53°C) to high-heat environments (over 177°C).

This capability is critical in aerospace for components like turbine engines and auxiliary power units (APUs). It's also essential in the oil & gas industry for downhole tools and subsea equipment exposed to extreme environmental conditions.

High-Speed and Dry-Running Capability

The exceptionally low coefficient of friction of PTFE allows these seals to handle very high rotational speeds—in some aerospace applications, over 100 meters per second.

This property also means they can tolerate dry-running or poorly lubricated conditions that would cause a standard elastomer seal to overheat and be destroyed. This is crucial for gearboxes, motors, compressors, and robotics.

Purity and Biocompatibility

PTFE is non-toxic and biocompatible, making it ideal for sensitive applications.

In the medical field, these seals are used in surgical tools, hematology analyzers, and oxygen concentrators. The non-stick surface prevents contamination and ensures operational purity.

Key Applications Across Core Sectors

To understand their value, it's helpful to see where these seals are put to work.

In Oil & Gas and Chemical Processing

PTFE seals are found in the most demanding equipment, including high-pressure, high-temperature (HPHT) downhole tools, pumps handling chemical retardants, and valves managing corrosive process fluids.

In Aerospace and Defense

Reliability here is non-negotiable. PTFE seals are used in jet engine gearboxes, fuel pumps, hydraulic systems, and landing gear actuators on both commercial and military aircraft.

In Food, Beverage, and Pharmaceuticals

Equipment such as industrial mixers, extruders, and blowers rely on PTFE seals to ensure product purity and withstand aggressive clean-in-place (CIP) procedures.

In Heavy Industry and Automotive

In construction machinery like excavators and loaders, PTFE seals provide superior wear and temperature resistance. In the automotive sector, they are used in engine and transmission components that require long life and high performance.

Understanding the Trade-offs

While powerful, PTFE seals are not a universal solution. Their unique properties come with specific design considerations.

Limited Elasticity

Unlike rubber, PTFE is not naturally elastic. It relies on a metallic spring or an elastomer O-ring energizer to provide the consistent force needed for effective sealing. This makes them less forgiving of shaft imperfections than a standard rubber lip seal.

Higher Initial Cost

Engineered PTFE seals are a premium product. Their cost is higher than a commodity elastomer seal, but this is justified by significantly longer service life and reliability in conditions where a cheaper seal would lead to premature failure and costly downtime.

Installation Sensitivity

The rigid nature of PTFE means that installation requires more care than with a flexible elastomer seal. Using proper tools and procedures is critical to avoid damaging the seal lip.

Making the Right Choice for Your Application

Selecting a seal requires matching the material's strengths to your primary operational challenge.

- If your primary focus is chemical compatibility and purity: PTFE is the default choice for aggressive media in pharmaceutical, chemical, and food processing.

- If your primary focus is high-speed rotation or dry running: The low-friction nature of PTFE excels in gearboxes, motors, and spindles where elastomers would overheat.

- If your primary focus is an extreme temperature range (hot or cold): PTFE seals are essential for cryogenic applications and high-temperature environments found in aerospace and oil & gas.

- If your primary focus is cost-sensitivity in a standard environment: A conventional elastomer seal is often the more appropriate and economical solution for moderate temperatures, speeds, and pressures.

Ultimately, understanding these core properties allows you to specify a sealing solution that ensures reliability where it matters most.

Summary Table:

| Industry | Primary Application | Key PTFE Seal Benefit |

|---|---|---|

| Aerospace & Defense | Jet engine gearboxes, fuel pumps | Extreme temperature tolerance, high-speed capability |

| Oil & Gas | Downhole tools, subsea equipment | Chemical inertness, high-temperature performance |

| Chemical Processing | Pumps, valves, mixers | Superior chemical resistance |

| Food, Pharma & Medical | Mixers, surgical tools, analyzers | Purity, biocompatibility, non-contamination |

| Automotive & Heavy Machinery | Engine/transmission components, excavators | Wear resistance, long service life |

Facing extreme temperatures, aggressive chemicals, or high-speed challenges? Standard seals often fail where PTFE excels. KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We provide custom fabrication from prototypes to high-volume orders, ensuring your equipment operates reliably in the most demanding conditions.

Contact KINTEK today to discuss your specific application and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications