In any dynamic piping system, uncontrolled movement is a liability. Polytetrafluoroethylene (PTFE) expansion joints are highly specialized flexible connectors engineered to safely absorb this movement. Their primary function is to compensate for thermal expansion and contraction, isolate vibrations, and correct for minor misalignments, thereby protecting the integrity of the entire pipeline from stress-induced failure.

The core value of a PTFE expansion joint isn't just its flexibility, but its unparalleled chemical and thermal resistance. It is the definitive choice for protecting piping systems that handle corrosive materials or operate at extreme temperatures where other materials would quickly degrade.

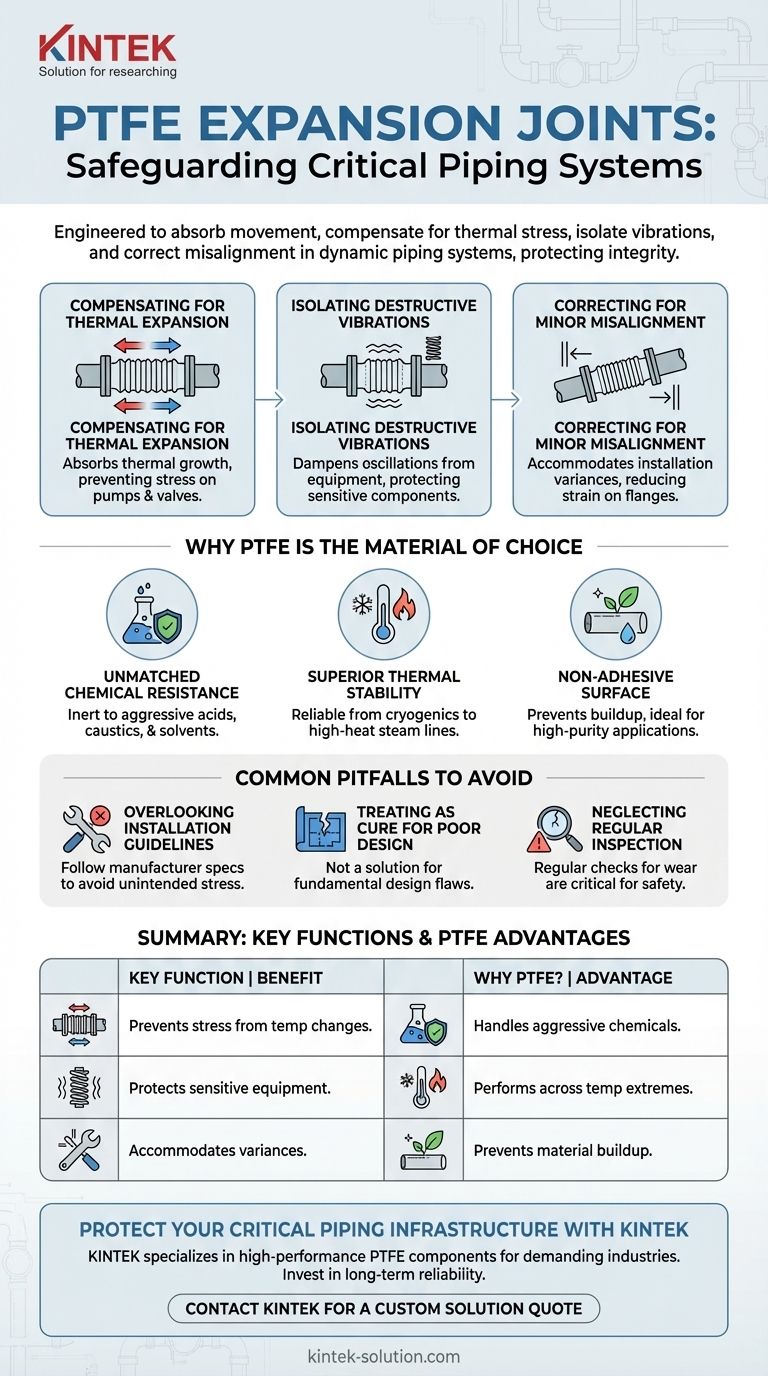

The Core Problems Solved by Expansion Joints

A piping system is rarely static. Temperature fluctuations, mechanical vibrations, and physical stresses create constant forces that can lead to leaks, cracks, and catastrophic failure. Expansion joints are designed to be the "weakest" point in the system in a controlled way, absorbing this energy so that more critical components do not have to.

Compensating for Thermal Expansion

Piping materials expand when heated and contract when cooled. Over long pipe runs, this movement can be significant, placing immense stress on fixed points like vessel nozzles, pumps, and valves. A PTFE expansion joint acts like an accordion, compressing and extending to absorb this thermal growth.

Isolating Destructive Vibrations

Equipment such as pumps, compressors, and engines transmit vibrations through the piping system. These constant oscillations can fatigue metal components over time. An expansion joint serves as a flexible break in the line, dampening the vibrations and isolating sensitive equipment from damage.

Correcting for Minor Misalignment

During construction or over the life of a facility, perfect pipe alignment is difficult to achieve and maintain. An expansion joint can accommodate minor parallel or angular misalignment, reducing the strain that would otherwise be placed on pipe flanges, welds, and fittings.

Why PTFE is the Material of Choice

While expansion joints can be made from materials like rubber or metal, PTFE offers a unique combination of properties that make it indispensable for demanding industrial applications.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals and corrosive agents. This makes it the only viable option for systems transporting aggressive acids, caustics, and solvents that would rapidly destroy rubber or metal joints.

Superior Thermal Stability

PTFE expansion joints can operate reliably across a wide range of temperatures, from cryogenic applications to high-temperature steam lines in power plants. This stability ensures predictable performance where other materials would become brittle or lose their structural integrity.

Non-Adhesive Surface

The surface of PTFE is inherently non-stick. In industries like food production and pharmaceuticals, this prevents material buildup, reduces the risk of contamination, and simplifies cleaning and sterilization processes, ensuring system purity.

Common Pitfalls to Avoid

The effectiveness of a PTFE expansion joint is entirely dependent on its correct application and installation. Misunderstanding its limitations can lead to premature failure.

Overlooking Installation Guidelines

Each expansion joint is engineered for a specific range of movement. Failing to follow manufacturer guidelines for installation, such as pre-compression or ensuring proper alignment, will place unintended stress on the joint and dramatically shorten its service life.

Treating it as a Cure for Poor Design

An expansion joint is meant to absorb the expected movements of a well-designed system. It is not a solution for fundamental design flaws, such as inadequate pipe support or extreme misalignment.

Neglecting Regular Inspection

While durable, PTFE joints are not immune to wear and damage, especially in high-pressure or high-cycle environments. Regular visual inspections for signs of cracking, discoloration, or leakage are critical for preventative maintenance and ensuring system safety.

Making the Right Choice for Your System

Selecting the correct component is critical for ensuring the safety and longevity of your piping infrastructure.

- If your primary focus is handling aggressive chemicals: PTFE is the industry standard due to its exceptional and near-universal corrosion resistance.

- If your primary focus is maintaining system purity: The non-adhesive properties of PTFE make it the ideal choice for food, beverage, and pharmaceutical applications.

- If your primary focus is managing high temperatures or pressures: PTFE's thermal stability offers reliable and safe performance in demanding environments like power plants and chemical reactors.

Ultimately, choosing a PTFE expansion joint is an investment in the long-term reliability and safety of your most critical piping infrastructure.

Summary Table:

| Key Function | Benefit |

|---|---|

| Compensates for Thermal Expansion | Prevents stress on pipes, pumps, and valves from temperature changes. |

| Isolates Vibrations | Protects sensitive equipment from damage caused by pumps and compressors. |

| Corrects Minor Misalignment | Accommodates installation variances, reducing strain on flanges and welds. |

| Why PTFE? | Advantage |

| Unmatched Chemical Resistance | Handles aggressive acids, caustics, and solvents where other materials fail. |

| Superior Thermal Stability | Performs reliably from cryogenic temperatures to high-heat steam lines. |

| Non-Adhesive Surface | Prevents material buildup, ideal for food, pharma, and high-purity applications. |

Protect Your Critical Piping Infrastructure with Precision-Engineered PTFE Components

Is your piping system at risk from thermal stress, vibration, or corrosive chemicals? KINTEK specializes in manufacturing high-performance PTFE components, including custom expansion joints, seals, liners, and labware.

We serve demanding industries like semiconductor, medical, laboratory, and industrial processing, where failure is not an option. Our expertise ensures you get a solution tailored to your specific pressure, temperature, and chemical resistance requirements—from prototypes to high-volume production.

Invest in long-term reliability. Contact KINTEK today to discuss your application and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability