A PTFE seat butterfly valve achieves its exceptional corrosion resistance by creating an impenetrable barrier. This design ensures that the valve's core metal body and stem are completely isolated from the process fluid, which only comes into contact with the chemically inert Polytetrafluoroethylene (PTFE) lining.

The fundamental strategy of a PTFE-lined valve is not to make the metal components resistant to corrosion, but to prevent them from ever touching the corrosive media in the first place. The PTFE liner acts as a total protective shield.

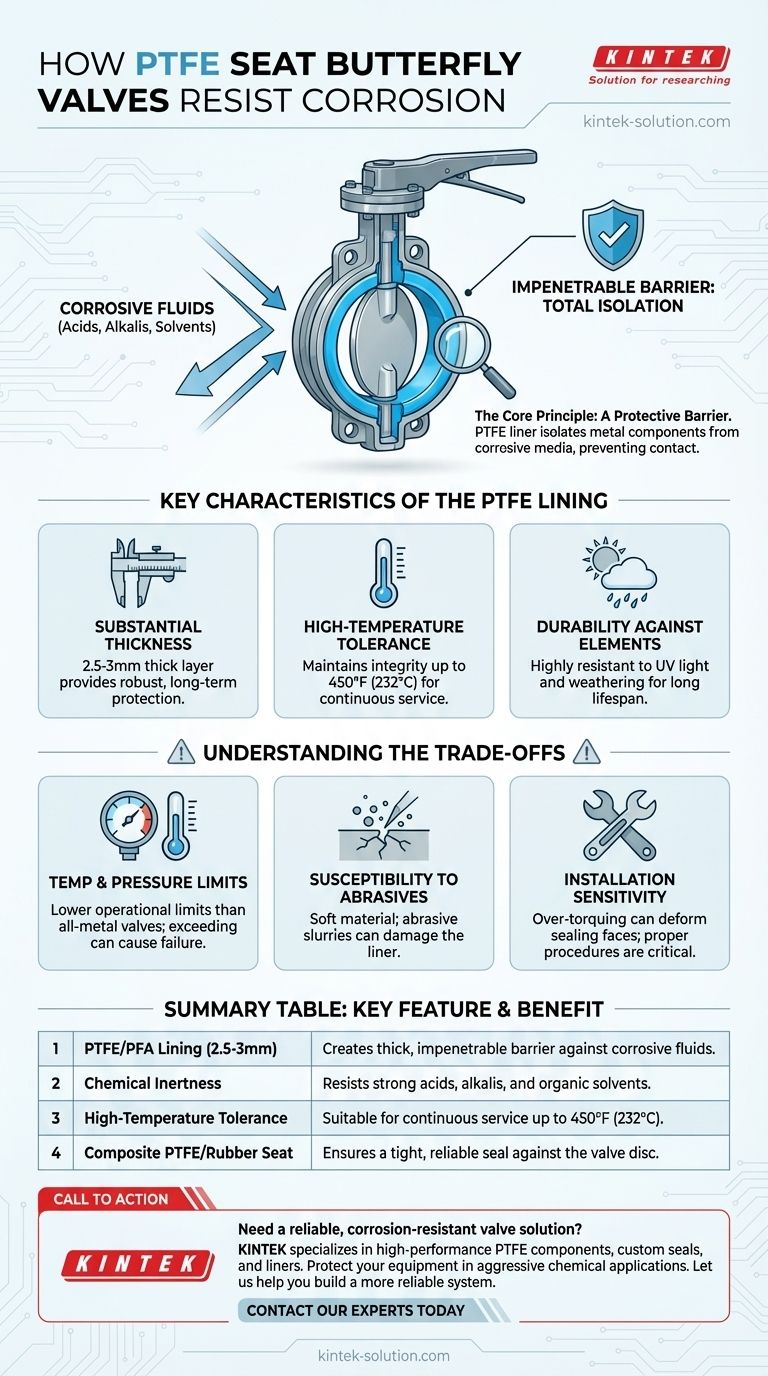

The Core Principle: A Protective Barrier

A PTFE-lined valve is engineered around the concept of complete isolation. The design effectively places a corrosion-proof plastic valve inside the structural metal housing of a traditional butterfly valve.

Isolate and Protect

The primary mechanism is a thick, continuous liner made of PTFE (also known by the brand name Teflon) that covers all wetted surfaces of the valve.

This means the corrosive acid, alkali, or solvent flowing through the pipe never makes contact with the cast iron, carbon steel, or stainless steel valve body.

The Chemical Inertness of PTFE

The choice of PTFE is critical. This material is one of the most chemically inert substances known, making it impervious to chemical attack and oxidation.

It reliably withstands a vast range of aggressive media, including strong acids, strong alkalis, aqua regia, and all organic solvents.

Ensuring a Perfect Seal

The design often features a rubber seat lined with PTFE. This combines the flexibility and sealing power of rubber with the chemical resistance of PTFE.

This composite construction ensures a tight, reliable seal against the valve disc, preventing any leakage that could compromise the metal components and lead to failure.

Key Characteristics of the PTFE Lining

The effectiveness of the valve is directly tied to the quality and properties of its protective liner. These features are essential to its performance in harsh environments.

Substantial Thickness

The PTFE or PFA lining is typically 2.5-3mm thick. This substantial layer provides robust, long-term protection and is not merely a thin coating that can be easily scratched or permeated.

High-Temperature Tolerance

PTFE maintains its integrity and protective qualities at elevated temperatures, often rated for continuous service up to 450°F (232°C). This makes it suitable for a wide range of chemical processes.

Durability Against Elements

Beyond chemical resistance, PTFE is also highly resistant to weathering and degradation from UV light. This ensures a long operational lifespan, even in outdoor installations exposed to harsh conditions.

Understanding the Trade-offs

While highly effective, PTFE-lined valves are not a universal solution. Understanding their limitations is key to proper application and avoiding premature failure.

Temperature and Pressure Limits

PTFE is a polymer, not a metal. It has clear operational limits for temperature and pressure that are generally lower than those of all-metal or alloy valves. Exceeding these specifications can lead to liner failure.

Susceptibility to Abrasives

PTFE is a relatively soft material. These valves are best suited for clean fluids. Applications involving abrasive slurries or suspended solids can physically damage the liner, compromising its protective function and causing leaks.

Installation Sensitivity

The integrity of the liner is paramount. Over-torquing flange bolts during installation can crush or deform the PTFE sealing faces, creating a leak path. Proper installation procedures are critical to the valve's long-term performance.

Making the Right Choice for Your Goal

Selecting the right valve requires matching its capabilities to the specific demands of your system.

- If your primary focus is handling highly aggressive chemicals: The near-universal chemical inertness of a PTFE-lined valve makes it an excellent and cost-effective choice.

- If your application involves moderate temperatures and non-abrasive fluids: This valve provides exceptional, reliable protection within its specified operational limits.

- If you need to prevent fluid contamination: The non-stick, inert nature of PTFE ensures that nothing leaches from the valve body into the process medium.

By leveraging the principle of total isolation, the PTFE-lined butterfly valve offers a powerful solution for safely managing corrosion in your system.

Summary Table:

| Key Feature | Benefit |

|---|---|

| PTFE/PFA Lining (2.5-3mm) | Creates a thick, impenetrable barrier against corrosive fluids. |

| Chemical Inertness | Resists strong acids, alkalis, and organic solvents. |

| High-Temperature Tolerance | Suitable for continuous service up to 450°F (232°C). |

| Composite PTFE/Rubber Seat | Ensures a tight, reliable seal against the valve disc. |

Need a reliable, corrosion-resistant valve solution for your critical process?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom seals, liners, and specialized labware. Our expertise ensures your equipment is protected against even the most aggressive chemicals in semiconductor, medical, laboratory, and industrial applications.

We offer custom fabrication from prototypes to high-volume orders, tailored to your exact specifications. Let us help you build a more reliable and durable system.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the material options for PTFE O-ring seals? A Guide to High-Performance Filled PTFE Compounds

- How are PTFE rods utilized in electronic and electrical applications? Unlock Superior Performance & Reliability

- How does PTFE's chemical resistance benefit industrial applications? Boost Equipment Lifespan & Safety

- Where is PTFE packing typically used? The Go-To Sealing Solution for Harsh Environments

- How do stainless steel impellers compare to PTFE impellers in terms of non-stick properties? Prevent Residue & Buildup

- How do PTFE properties benefit butterfly valve performance? Enhance Durability & Efficiency

- What are PTFE bellows and diaphragms, and why are they important in critical systems?

- What materials are used in PTFE bellows and what compliance standards do they meet? Ensure Safety and Performance