At its core, a Teflon check valve is an automatic safety device used in control systems to ensure that a process medium—whether liquid or gas—can only flow in a single, intended direction. Its primary function is to prevent backflow, which can damage equipment, contaminate processes, and create unsafe conditions. The use of Teflon (PTFE) as a lining material is a specific design choice for handling highly corrosive or high-temperature substances.

The function of a check valve is to enforce one-way flow, but the function of a Teflon check valve is to perform this critical safety task under chemically aggressive or high-temperature conditions that would cause standard valves to fail.

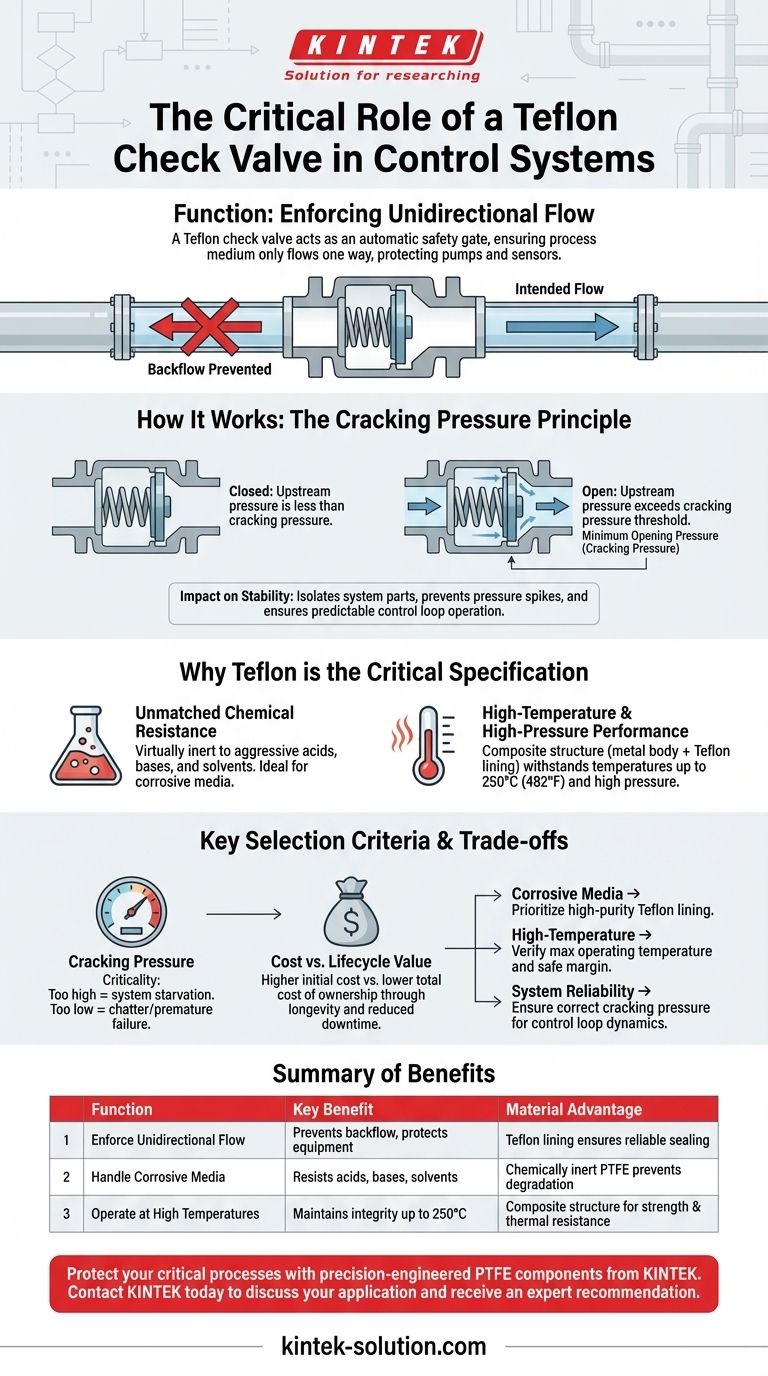

The Core Function: Enforcing Unidirectional Flow

A check valve is one of the simplest and most crucial components in any fluid control system. Its purpose is singular: to act as a one-way gate.

How It Works: The Cracking Pressure Principle

A check valve remains closed by default. It only opens when the pressure on the upstream side becomes great enough to overcome the valve's internal mechanism (a spring or gravity).

This minimum opening pressure is known as the cracking pressure. Once this threshold is met, the valve opens and allows flow. If the upstream pressure falls below this point, or if backpressure from the downstream side increases, the valve automatically snaps shut.

The Impact on Control Loop Stability

In an automated control loop, consistent and predictable flow is essential. Backflow can introduce pressure spikes, disrupt measurements from sensors, and damage sensitive upstream equipment like pumps.

By preventing reverse flow, a check valve isolates different parts of the system, ensuring that each component operates within its designed parameters and contributing to overall system stability and safety.

Why "Teflon" is the Critical Specification

While any check valve prevents backflow, the material it's made from dictates its application. Choosing a Teflon-lined valve is a deliberate engineering decision for demanding environments.

Unmatched Chemical Resistance

Teflon is virtually inert to almost all industrial chemicals, including aggressive acids, bases, and solvents. This makes it the ideal choice for systems handling corrosive media that would quickly degrade metal or plastic valves.

High-Temperature and High-Pressure Performance

Teflon-lined valves are composite structures. They feature a robust metal body (like cast iron or stainless steel) that can withstand high pressure and physical impact.

The internal Teflon lining provides the chemical and thermal barrier, with many designs rated for continuous service at temperatures up to 250°C (482°F). This combination provides strength and resistance in a single component.

Understanding the Trade-offs and Selection Criteria

Improper valve selection is a common point of failure that can compromise both system performance and safety. Understanding the key variables is critical.

The Criticality of Cracking Pressure

Specifying the correct cracking pressure is non-negotiable. If the cracking pressure is too high, the valve may not open during normal operation, starving the system.

If it's too low, the valve might "chatter" (open and close rapidly) with minor pressure fluctuations, leading to premature wear and potential failure.

Cost vs. Lifecycle Value

Teflon-lined valves carry a higher initial cost than simple commodity check valves. However, this cost must be weighed against the potential cost of failure.

In a corrosive environment, a cheaper valve may fail in weeks or months, causing costly downtime, process contamination, and safety hazards. The Teflon valve's longevity represents a lower total cost of ownership in these applications.

Making the Right Choice for Your System

Selecting the correct Teflon check valve requires matching its specifications to your system's precise operational demands.

- If your primary focus is handling highly corrosive media: Prioritize a valve with a thick, high-purity Teflon lining to ensure maximum chemical inertness and a long service life.

- If your primary focus is high-temperature processes: Verify the valve's maximum operating temperature and ensure it provides a safe margin above your system's peak thermal conditions.

- If your primary focus is system reliability: Ensure the cracking pressure is specified correctly for your control loop's dynamics to prevent backflow without impeding normal operation.

Ultimately, the right Teflon check valve acts as a silent guardian, protecting your system's integrity and preserving your process's profitability.

Summary Table:

| Function | Key Benefit | Material Advantage |

|---|---|---|

| Enforce Unidirectional Flow | Prevents backflow, protects pumps & sensors | Teflon lining ensures reliable sealing |

| Handle Corrosive Media | Resists acids, bases, and solvents | Chemically inert PTFE prevents degradation |

| Operate at High Temperatures | Maintains integrity up to 250°C (482°F) | Composite metal/PTFE structure for strength & thermal resistance |

Protect your critical processes with precision-engineered PTFE components from KINTEK.

Is your control system handling aggressive chemicals or operating at high temperatures? A custom-fabricated Teflon check valve from KINTEK can be the key to preventing costly downtime, equipment damage, and process contamination.

We specialize in manufacturing high-performance PTFE components—including seals, liners, labware, and custom parts like check valves—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a solution that matches your exact pressure, temperature, and chemical resistance requirements, from prototype to high-volume production.

Contact KINTEK today to discuss your application and receive a expert recommendation.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments