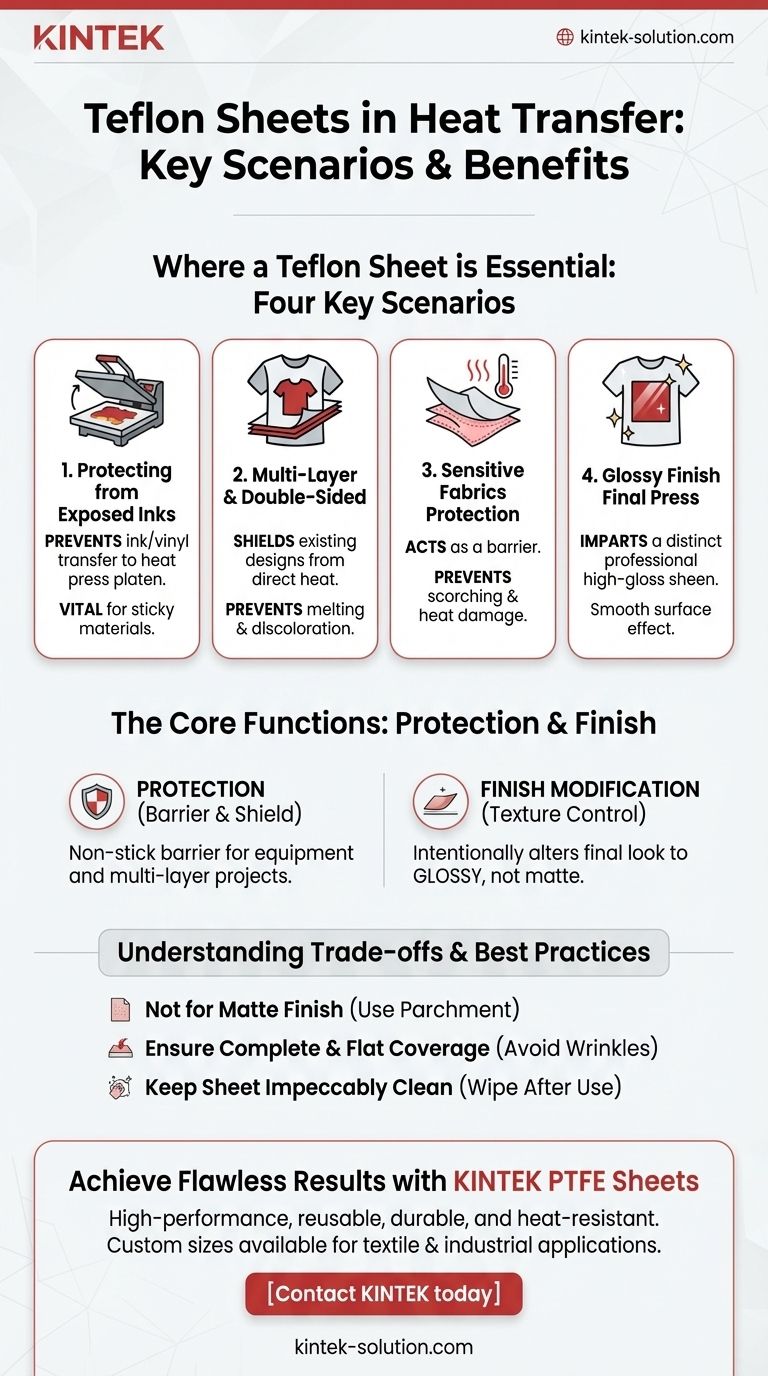

In heat transfer applications, a Teflon sheet is essential in four key scenarios. It is used to protect your heat press from exposed inks, to shield existing designs during multi-layer or double-sided applications, to prevent scorching on sensitive fabrics, and to impart a distinct glossy finish to the final transfer.

A Teflon sheet is not merely a protective accessory; it is a strategic tool that gives you control over your final product. It acts as a durable, non-stick barrier that prevents damage while allowing you to deliberately alter the texture and finish of your design.

The Core Functions of a Teflon Sheet

To understand when to use a Teflon sheet, you must first understand its two primary functions: protection and finish modification. These capabilities stem directly from the material's unique properties.

Function 1: Protecting Your Project and Equipment

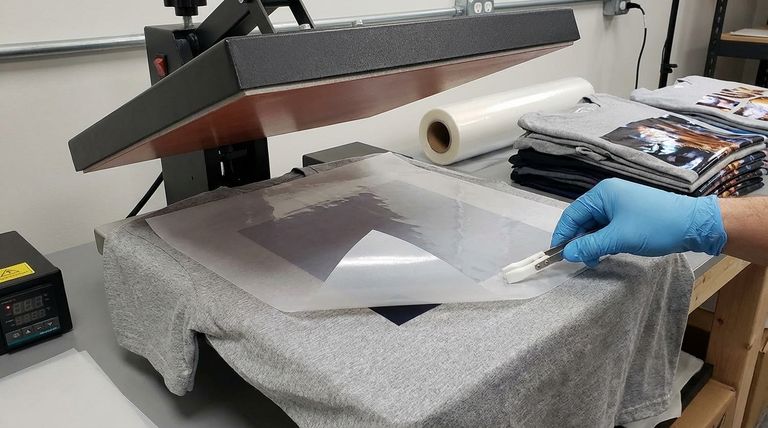

The most common use for a Teflon sheet is as a protective barrier. Its non-stick surface is invaluable when working with inks or vinyl that may have exposed, sticky areas.

Without a cover sheet, these materials can transfer to the upper platen of your heat press, potentially ruining both the machine and your next project.

This protective quality is critical when creating complex, multi-layered designs or printing on both sides of a garment. The sheet shields the already-pressed layers from direct heat, preventing them from melting, discoloring, or sticking to the platen.

Function 2: Modifying the Final Finish

A Teflon sheet directly influences the final look and feel of your heat transfer. Its perfectly smooth surface imparts a shiny, glossy finish onto the heat transfer vinyl (HTV) or ink it covers.

This effect is intentional. If your goal is a high-gloss, commercial look, pressing with a Teflon sheet is the standard method for achieving it. Conversely, if you desire a matte finish, you would use a different cover like parchment or kraft paper.

The Science Behind the Sheet

Teflon's effectiveness comes from its core chemical properties. It is a polymer with extremely high temperature resistance and a very low coefficient of friction—which is why it's famous for being non-stick.

These characteristics ensure it can withstand heat press temperatures without degrading while preventing anything from adhering to its surface. This makes it a durable and reusable tool for any serious heat press workflow.

Understanding the Trade-offs and Best Practices

While incredibly useful, a Teflon sheet is not a universal solution. Using it incorrectly or in the wrong situation can lead to undesirable results.

The Glossy Finish Isn't Always Desirable

The primary trade-off is the finish. If you or your client want a softer, more integrated matte look for your design, a Teflon sheet is the wrong choice. Its smoothing effect will work against this goal.

Ensure Complete and Flat Coverage

For the sheet to work effectively, it must be larger than your design and lie perfectly flat. Any wrinkles or folds in the Teflon sheet can be permanently pressed into your garment and transfer, ruining the final product.

Keep Your Sheet Clean

A Teflon sheet must be kept impeccably clean. Any stray ink, adhesive, or lint on the sheet can be transferred to your next project during pressing. Wipe it down with a soft cloth after each use, especially when working with screen print transfers or other "wet" inks.

How to Apply This to Your Project

Your choice of cover sheet should be a deliberate decision based on the specific outcome you want to achieve.

- If your primary focus is protecting your press and design: Always use a Teflon sheet for projects with exposed ink, multiple layers, or double-sided printing.

- If your primary focus is achieving a glossy, professional finish: Press your final layer with a Teflon sheet as the top cover to impart a characteristic sheen.

- If your primary focus is a matte or natural finish: Avoid the Teflon sheet for the final press and opt for parchment paper or a kraft paper cover instead.

Ultimately, mastering the use of a Teflon sheet is about controlling the final outcome of your work with precision.

Summary Table:

| Scenario | Primary Function | Key Benefit |

|---|---|---|

| Protecting from exposed inks | Equipment Protection | Prevents damage to heat press platen |

| Multi-layer/double-sided applications | Design Protection | Shields existing designs from direct heat |

| Pressing sensitive fabrics | Fabric Protection | Prevents scorching and damage |

| Final press for glossy finish | Finish Modification | Imparts a professional, high-gloss sheen |

Achieve Flawless Results with KINTEK PTFE Sheets

Mastering your heat transfer process requires the right tools. KINTEK manufactures high-performance PTFE (Teflon) sheets and components designed for precision and durability in demanding applications. Whether you're in the textile, promotional product, or specialized industrial sector, our sheets offer superior non-stick properties, exceptional temperature resistance, and consistent performance for reusable protection and perfect finishes.

We specialize in custom fabrication, from prototypes to high-volume orders, ensuring you get the exact size and specification you need.

Ready to enhance your heat press workflow with reliable, high-quality PTFE sheets?

Contact KINTEK today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the general benefits of using PTFE for sealing applications? Master Chemical & Thermal Resistance

- What are some common industrial applications of PTFE sheets? Solve Friction, Corrosion, and Insulation Challenges

- What manufacturing methods are used to produce custom PTFE products? A Guide to Molding and Machining

- What are the general properties and applications of Teflon industrial coatings? Solve Complex Engineering Challenges

- What type of gasket is particularly suitable for industries dealing with hazardous chemicals? The Definitive Choice for Safety

- What are the features of PTFE with a Proprietary Organic Fill? Protect Soft Metals with Low-Friction Performance

- How should one choose the right type of PTFE gasket? A Guide to Optimal Seal Performance

- What are common applications of machined Teflon parts? Solve Friction, Chemical, and Electrical Challenges