At its core, machined Teflon (PTFE) is a problem-solver for environments where other materials fail. Its most common applications include high-performance seals and gaskets, self-lubricating bearings and bushings, and superior electrical insulators. You will find these components in demanding industries like aerospace, medical, chemical processing, and food manufacturing.

The decision to use machined Teflon is rarely about mechanical strength. Instead, it is chosen for its unique combination of extreme chemical resistance, an exceptionally low coefficient of friction, and excellent dielectric properties, making it the default material for very specific engineering challenges.

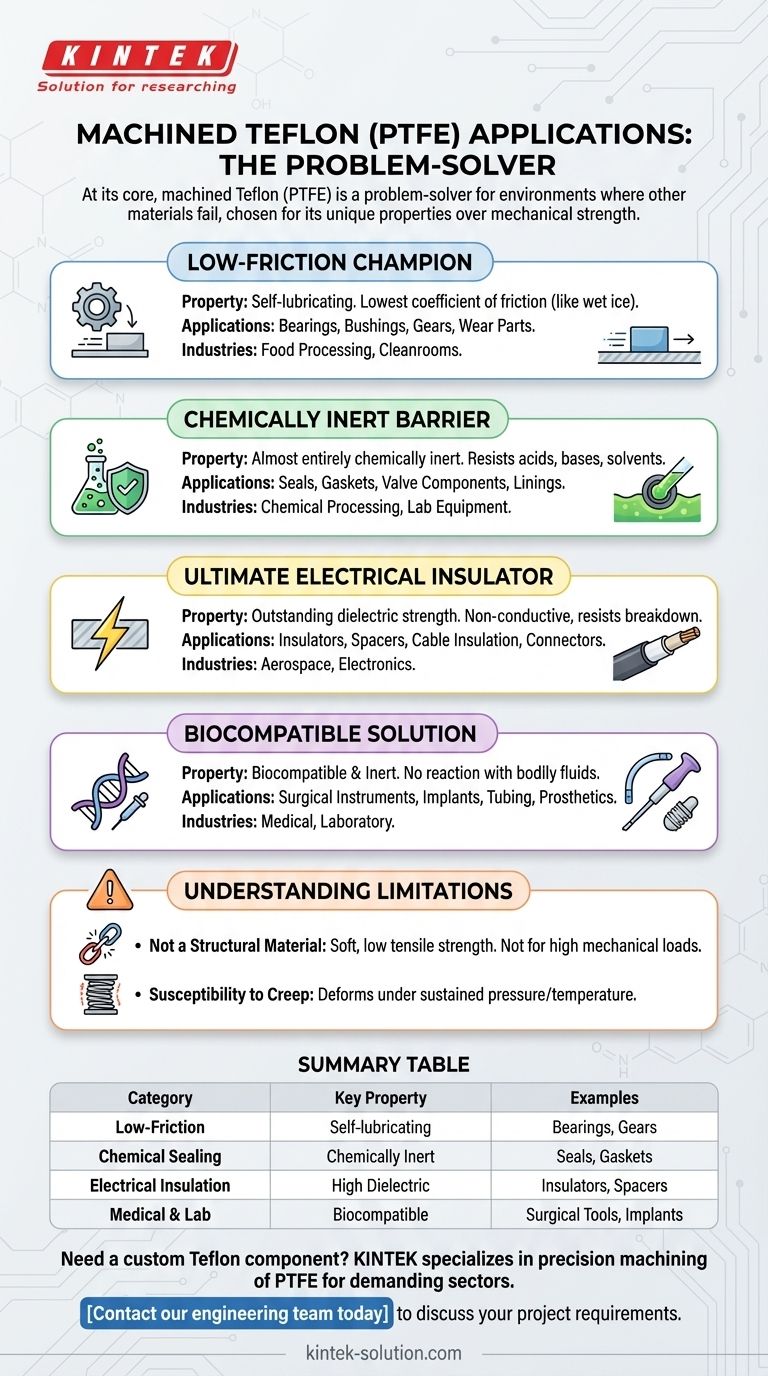

Why Teflon Excels: Linking Properties to Applications

Teflon's value comes from a set of distinct characteristics. Understanding how these properties drive its use is key to knowing when to specify it for a part.

The Low-Friction Champion: Bearings, Bushings, and Wear Parts

Teflon possesses one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This makes it self-lubricating.

This property is ideal for bearings, bushings, gears, and other wear parts where external lubricants are impractical or would contaminate the system, such as in food processing or cleanroom environments.

The Chemically Inert Barrier: Seals, Gaskets, and Valve Components

PTFE is almost entirely chemically inert, meaning it resists corrosion and degradation from the most aggressive acids, bases, and solvents.

This makes it the premier choice for seals, gaskets, and valve components used in chemical processing, pipelines, and laboratory equipment. These parts maintain their integrity even when exposed to harsh substances.

The Ultimate Electrical Insulator: Aerospace and Electronics

Teflon has outstanding dielectric strength and a low dissipation factor, meaning it does not conduct electricity and resists electrical breakdown even at high frequencies.

This is why it is extensively used for electrical insulators, spacers, and cable insulation, particularly in high-stakes aerospace and electronics applications where signal integrity and safety are paramount.

The Biocompatible Solution: Medical and Laboratory Equipment

Because of its inertness, Teflon is highly biocompatible; it does not react with bodily fluids and the human body does not reject it.

This property is critical for medical applications, including surgical instruments, implants, prosthetics, and tubing. Its non-reactive surface is also essential for scientific equipment where sample contamination must be avoided.

Understanding Teflon's Limitations

Objectivity requires acknowledging where a material is not the right fit. Teflon's unique strengths come with clear trade-offs.

Not a Structural Material

Teflon is a relatively soft material with low tensile strength and stiffness compared to engineering plastics like nylon or PEEK, and especially compared to metals.

It is not suitable for parts that must bear significant mechanical loads. It is a problem-solver for surface properties, not a structural backbone.

Susceptibility to Creep

Under sustained pressure, especially at elevated temperatures, Teflon can deform permanently. This phenomenon is known as creep.

Designers must account for this when using Teflon for seals or gaskets that will be under constant compression, as it can affect long-term sealing performance.

Making the Right Choice for Your Goal

Selecting Teflon should be a deliberate decision based on the primary challenge you need to solve.

- If your primary focus is reducing friction without lubrication: Teflon is an excellent choice for bearings, wear pads, and low-friction sliding components.

- If your primary focus is handling aggressive chemicals: Specify Teflon for seals, valve seats, and linings that need to survive corrosive environments.

- If your primary focus is high-frequency electrical insulation: Teflon is the industry standard for high-performance insulators and connectors.

- If your primary focus is biocompatibility or food safety: Its inert and non-stick nature makes it ideal for medical devices and food processing machinery.

Understanding Teflon's specific strengths is the key to successfully applying it where it can uniquely excel.

Summary Table:

| Application Category | Key Teflon Property | Common Part Examples |

|---|---|---|

| Low-Friction Parts | Self-lubricating | Bearings, Bushings, Gears |

| Chemical Sealing | Chemically inert | Seals, Gaskets, Valve components |

| Electrical Insulation | High dielectric strength | Insulators, Spacers, Cable insulation |

| Medical & Lab Equipment | Biocompatible & inert | Surgical tools, Implants, Tubing, Labware |

Need a custom Teflon component for your demanding application?

KINTEK specializes in precision machining of PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume production run, our expertise ensures a part that perfectly balances chemical resistance, low friction, and electrical properties for your unique challenge.

Contact our engineering team today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials