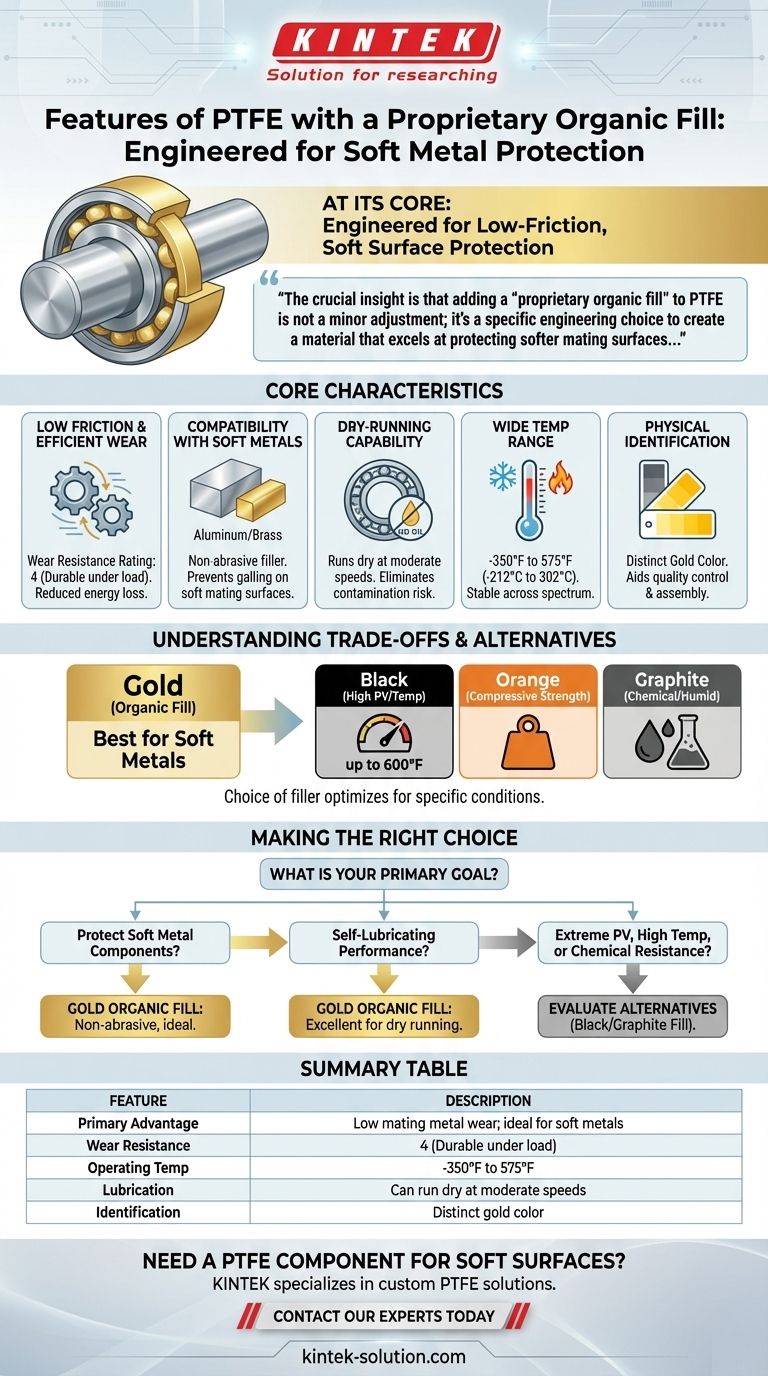

At its core, Polytetrafluoroethylene (PTFE) with a proprietary organic fill is an engineered material designed for efficient, low-friction performance, especially in applications involving soft metal surfaces. Its key features include excellent wear characteristics, the ability to run dry at moderate speeds, a very wide operating temperature range from -350°F to 575°F, and a distinct gold color for identification.

The crucial insight is that adding a "proprietary organic fill" to PTFE is not a minor adjustment; it's a specific engineering choice to create a material that excels at protecting softer mating surfaces in bearing and sealing applications, a task for which standard or differently filled PTFEs may be unsuitable.

Core Characteristics of This Material

The unique combination of base polymer (PTFE) and a specific filler creates a performance profile tailored for distinct mechanical challenges.

Low Friction and Efficient Wear

This material is defined by its low coefficient of friction and efficient wear characteristics. It is assigned a wear resistance rating of 4, indicating a durable composition under load.

This translates to longer component life and reduced energy loss in moving systems.

Compatibility with Soft Metals

A primary feature is its low mating metal wear. The organic filler is non-abrasive, making it an excellent choice for applications where the PTFE component runs against softer metals like aluminum, brass, or certain steels.

This prevents galling or damage to the more critical or expensive metal component.

Dry-Running Capability

Like many PTFE compounds, it can run dry without external lubrication at moderate surface speeds. This simplifies system design and is critical for environments where lubricants could cause contamination or are impractical to apply.

Wide Operating Temperature Range

The material remains stable and functional across an exceptionally broad temperature spectrum, from -350°F to 575°F (-212°C to 302°C). This makes it suitable for everything from cryogenic processes to high-temperature industrial machinery.

Physical Identification

For practical purposes, this specific formulation is easily identifiable by its distinct gold color. This aids in quality control and ensures the correct material is used during assembly and maintenance.

Understanding the Trade-offs and Alternatives

No single material is perfect for every situation. The choice of filler is a critical trade-off, optimizing PTFE for one set of conditions while making it less suitable for others.

When to Consider Other Fillers

The "proprietary organic fill" is optimized for soft surfaces. If your application has different primary demands, other fillers may be superior.

- High PV and Temperature: A different proprietary fill, black in color, is engineered for high Pressure-Velocity (PV) and high-temperature applications up to 600°F.

- Compressive Strength: A modified PTFE with a "premium organic fill," orange in color, is specifically designed for better compressive strength.

- Humid or Chemical Environments: A graphite-filled PTFE offers very good wear resistance and high chemical compatibility, making it ideal for fluid or high-humidity applications.

The Context of "Wear Resistance"

The provided "wear resistance rating" is a useful benchmark for comparison. The gold organic fill has a rating of 4, while a graphite fill has a rating of 2.

However, this number is relative. Real-world performance depends entirely on the complete system: the load, speed, temperature, and the hardness and finish of the mating surface.

Making the Right Choice for Your Goal

Selecting the correct material requires aligning its specific strengths with the primary demands of your application.

- If your primary focus is protecting soft metal components: This gold-colored, organically filled PTFE is specifically designed to be non-abrasive and is an ideal choice.

- If your primary focus is self-lubricating performance: Its ability to run dry at moderate speeds makes it excellent for bearing and sealing applications where external lubricants are undesirable.

- If your primary focus is extreme high-pressure, high-velocity (PV), or chemical resistance: You should evaluate alternative fillers, such as the black proprietary fill or graphite-filled PTFE, which are engineered for those specific stresses.

Ultimately, choosing the right filled PTFE is about matching the unique enhancements provided by the filler to the specific challenges of your engineering problem.

Summary Table:

| Feature | Description |

|---|---|

| Primary Advantage | Low mating metal wear; ideal for soft metals (aluminum, brass) |

| Wear Resistance Rating | 4 (Durable under load) |

| Operating Temperature | -350°F to 575°F (-212°C to 302°C) |

| Lubrication | Can run dry at moderate speeds |

| Identification | Distinct gold color |

Need a PTFE component that protects your soft metal surfaces?

KINTEK specializes in precision manufacturing of custom PTFE components, including seals, liners, and bearings with proprietary organic fills. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions from prototypes to high-volume production.

Contact our experts today to discuss how our filled PTFE materials can solve your specific application challenges and extend the life of your equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments