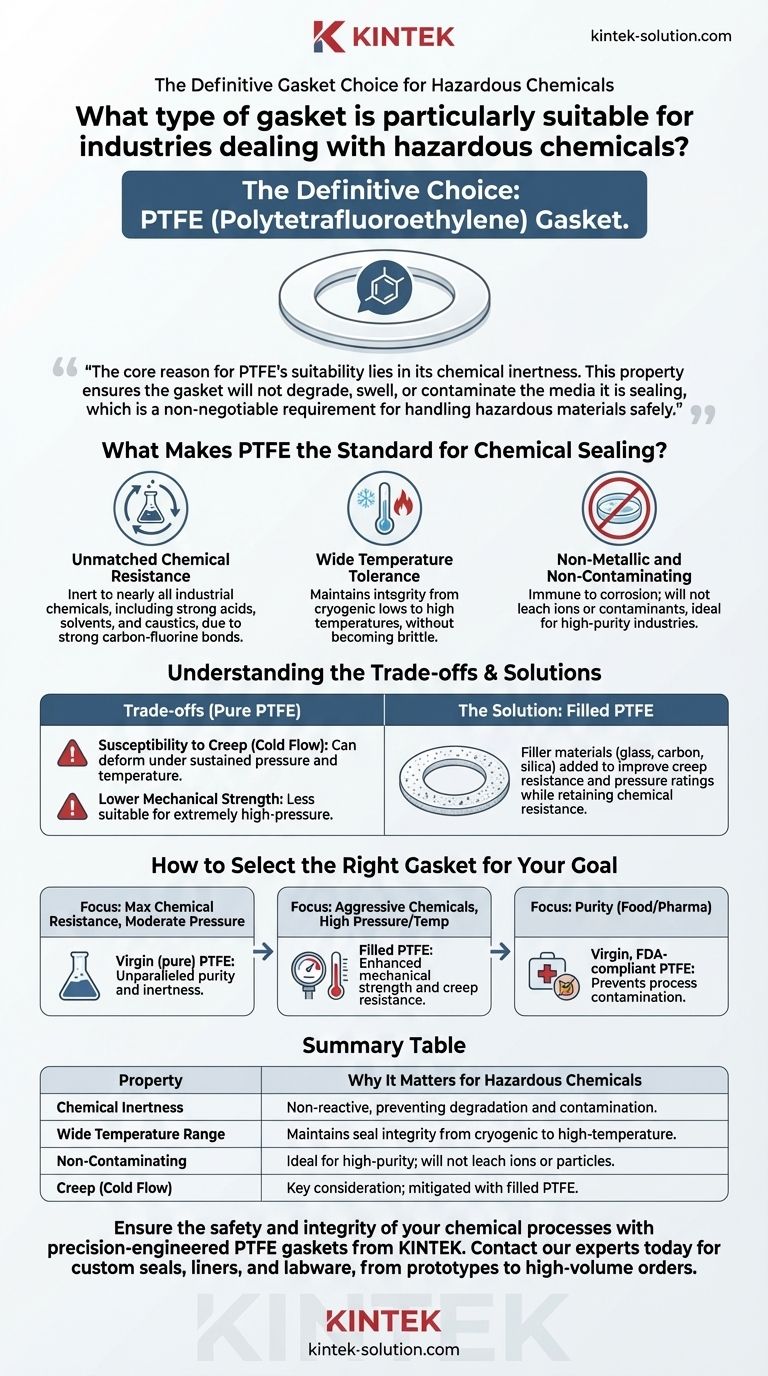

For industries dealing with hazardous chemicals, the definitive choice is a PTFE (Polytetrafluoroethylene) gasket. Its unique molecular structure makes it exceptionally non-reactive, providing a reliable and safe seal against a vast range of aggressive and corrosive substances where other materials would quickly fail.

The core reason for PTFE's suitability lies in its chemical inertness. This property ensures the gasket will not degrade, swell, or contaminate the media it is sealing, which is a non-negotiable requirement for handling hazardous materials safely.

What Makes PTFE the Standard for Chemical Sealing?

The selection of a gasket for hazardous applications is a critical safety decision. PTFE has become the industry benchmark due to a specific combination of inherent properties that make it uniquely suited for these demanding environments.

Unmatched Chemical Resistance

The strength of the carbon-fluorine bonds in PTFE's molecular structure is exceptionally high. This makes the material non-reactive, or inert, to nearly all industrial chemicals, including strong acids, solvents, and caustics.

Wide Temperature Tolerance

Many chemical processes involve extreme temperatures. PTFE gaskets maintain their integrity and sealing capability across a broad thermal range, from cryogenic lows to high-temperature applications, without becoming brittle or degrading.

Non-Metallic and Non-Contaminating

Being a non-metallic polymer, PTFE is immune to the corrosion that affects metal gaskets. This also means it will not leach ions or other contaminants into the process media, a critical factor for high-purity industries like pharmaceuticals and food processing.

Understanding the Trade-offs

While PTFE is superior in chemical applications, no material is without limitations. Understanding its mechanical properties is crucial for proper implementation and to avoid seal failure.

Susceptibility to Creep

The most significant trade-off of pure PTFE is its tendency for creep, or "cold flow." Under sustained pressure and temperature, the material can deform over time, potentially leading to a loss of bolt torque and a compromised seal.

Lower Mechanical Strength

Compared to metallic or semi-metallic gaskets, pure PTFE is a softer material. This makes it less suitable for extremely high-pressure applications without some form of reinforcement.

The Solution: Filled PTFE

To overcome these mechanical limitations, manufacturers often add filler materials like glass, carbon, or silica to the PTFE. These filled PTFE gaskets offer significantly improved resistance to creep and higher pressure ratings while retaining excellent chemical resistance.

How to Select the Right Gasket for Your Goal

Choosing the correct gasket variant is essential for ensuring both safety and operational reliability in your specific application.

- If your primary focus is maximum chemical resistance for moderate pressure: Virgin (pure) PTFE is often the ideal choice due to its unparalleled purity and inertness.

- If your primary focus is sealing aggressive chemicals under high pressure or temperature: A filled PTFE gasket is necessary to provide the mechanical strength and creep resistance required to maintain a long-term seal.

- If your primary focus is purity for food, medical, or pharmaceutical use: Always specify a virgin, FDA-compliant PTFE gasket to prevent any possibility of process contamination.

Understanding these material properties is the key to selecting a seal that guarantees both safety and performance.

Summary Table:

| Property | Why It Matters for Hazardous Chemicals |

|---|---|

| Chemical Inertness | Non-reactive with nearly all acids, solvents, and caustics, preventing degradation and contamination. |

| Wide Temperature Range | Maintains seal integrity from cryogenic to high-temperature processes. |

| Non-Contaminating | Ideal for high-purity industries; will not leach ions or particles into the media. |

| Creep (Cold Flow) | A key consideration; can be mitigated with filled PTFE for high-pressure applications. |

Ensure the safety and integrity of your chemical processes with precision-engineered PTFE gaskets from KINTEK.

Whether you require the ultimate purity of virgin PTFE for pharmaceutical applications or the enhanced mechanical strength of filled PTFE for high-pressure systems, our custom fabrication expertise ensures a perfect seal for your specific needs. We serve the semiconductor, medical, laboratory, and industrial sectors with components built for reliability.

Contact our experts today to discuss your application and receive a quote for custom PTFE seals, liners, and labware, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications