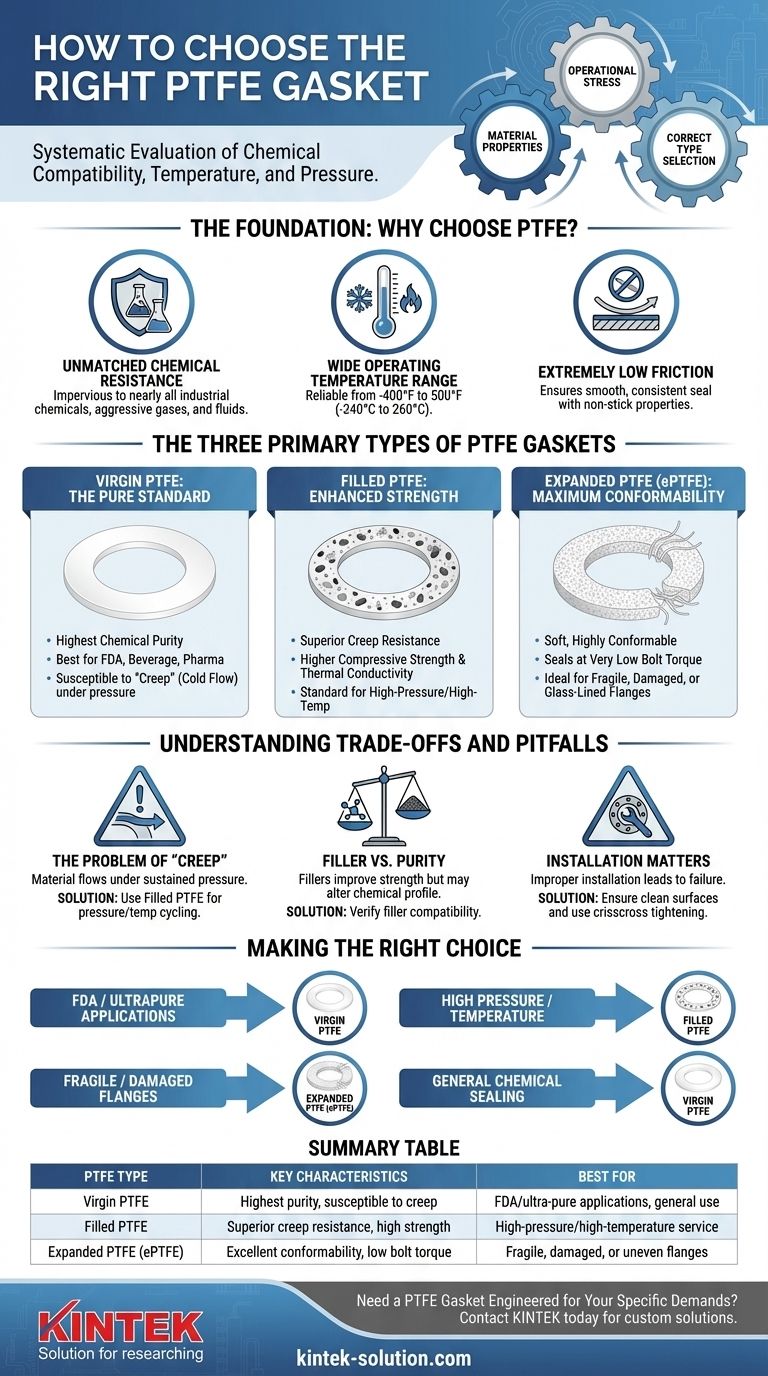

Choosing the right Polytetrafluoroethylene (PTFE) gasket requires a systematic evaluation of your application's specific demands. The correct selection hinges on matching the material's properties—primarily chemical compatibility, temperature range, and pressure rating—to the operational stress it will endure, and then selecting the appropriate type: Virgin, Filled, or Expanded PTFE.

The core challenge is not simply choosing PTFE, but understanding its limitations. While all PTFE offers elite chemical resistance, selecting the right variant—whether it's pure, filled with reinforcing agents, or expanded for conformability—is the critical step to preventing seal failure in demanding industrial environments.

The Foundation: Why Choose PTFE?

Before selecting a specific type, it's essential to understand the inherent advantages of the base material. PTFE is specified for applications where other materials would quickly fail.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials used in industry. It is non-reactive and impervious to degradation from nearly all industrial chemicals, aggressive gases, and fluids.

Wide Operating Temperature Range

Standard PTFE performs reliably across an exceptionally broad temperature spectrum, typically from -400°F to 500°F (-240°C to 260°C).

Extremely Low Friction

The material has an exceptionally low coefficient of friction, which contributes to its "non-stick" properties and helps ensure a smooth, consistent seal under compression.

The Three Primary Types of PTFE Gaskets

The most critical decision is choosing the correct form of PTFE. Each type is engineered to solve a different set of problems.

Virgin PTFE: The Pure Standard

This is pure, unadulterated PTFE. It offers the highest level of chemical resistance and is often required for food, beverage, and pharmaceutical applications due to its purity.

However, it is the softest variant and is susceptible to "creep" or "cold flow," where the material deforms permanently under sustained pressure, especially at elevated temperatures.

Filled PTFE: Enhanced for Strength and Stability

To counteract the weaknesses of virgin PTFE, inert filler materials are added. Common fillers like glass, carbon, or graphite dramatically improve the gasket's mechanical properties.

Filled PTFE offers superior resistance to creep, higher compressive strength, and better thermal conductivity. This makes it the standard choice for high-pressure or high-temperature service.

Expanded PTFE (ePTFE): Maximum Conformability

Expanded PTFE is a soft, highly conformable material created by expanding virgin PTFE. This process creates a porous, fibrous structure that compresses into a tough, dense gasket under load.

Its primary advantage is its ability to seal effectively with very low bolt torque. This makes it ideal for sealing old, damaged, or fragile flanges (like glass-lined or plastic) that could crack under high compressive loads.

Understanding the Trade-offs and Pitfalls

Selecting the optimal gasket requires acknowledging the compromises inherent in each material choice. An incorrect assessment here is a frequent source of seal failure.

The Problem of "Creep"

The single biggest weakness of Virgin PTFE is creep (cold flow). Under sustained pressure and temperature, the material slowly flows out of the flange, leading to a loss of bolt torque and eventual leakage. For any application involving significant pressure or temperature cycling, Filled PTFE is the safer choice.

Filler Material vs. Chemical Purity

While fillers dramatically improve mechanical strength, they can slightly alter the material's chemical compatibility profile. Always verify that the specific filler material is resistant to the media in your system. This is also why Virgin PTFE remains the standard for applications demanding absolute purity, such as FDA-compliant processes.

Gasket Thickness and Flange Condition

A common mistake is using a gasket that is too thick. While a thicker gasket can help seal a warped or uneven flange, it also provides more material that can creep or extrude. A thinner gasket provides a stronger, more stable seal on flat, high-quality surfaces.

Installation Is Not an Afterthought

Even the perfect gasket will fail if installed improperly. Ensure flange surfaces are clean and that bolts are tightened incrementally using a crisscross pattern to apply even pressure.

Making the Right Choice for Your Application

Use your primary operational goal to guide your final decision. The right material becomes clear when you prioritize the most critical demand of your system.

- If your primary focus is FDA compliance or ultrapure applications: Virgin PTFE is your required starting point.

- If your primary focus is handling high pressure or temperature: A Filled PTFE gasket is essential to resist creep and maintain a long-term seal.

- If your primary focus is sealing fragile, damaged, or uneven flanges: Expanded PTFE (ePTFE) provides the necessary conformability at low bolt loads.

- If your primary focus is general-purpose chemical sealing at moderate conditions: Virgin PTFE is a reliable and cost-effective solution.

Matching the specific PTFE variant to your application's unique stresses is the definitive path to a secure and lasting seal.

Summary Table:

| PTFE Type | Key Characteristics | Best For |

|---|---|---|

| Virgin PTFE | Highest chemical purity, susceptible to creep | FDA/ultra-pure applications, general chemical sealing |

| Filled PTFE | Superior creep resistance, high strength | High-pressure/high-temperature service |

| Expanded PTFE (ePTFE) | Excellent conformability, low bolt torque | Fragile, damaged, or uneven flanges |

Need a PTFE Gasket Engineered for Your Specific Demands?

Choosing the right PTFE variant is critical for preventing seal failure. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring your gasket is perfectly matched to your application's chemical, temperature, and pressure requirements.

Let our experts help you achieve a secure, lasting seal. Contact KINTEK today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key properties of fluoroplastics used in PTFE lined valves? Ensure Purity and Reliability

- What issue can arise due to PTFE's softness during machining? Mastering Dimensional Accuracy

- What are the key properties of Teflon that affect its machining? Master the Challenges for Precision Parts

- What are the benefits of PTFE butterfly valves in industrial applications? Enhance Safety, Purity & Efficiency

- What is the typical bond strength of etched PTFE to metals? Achieve Reliable Sealing & Positioning

- What is the role of factory run tests for PTFE Lip Seals? De-Risk Your Critical Sealing Applications

- Why are PTFE bars considered essential in modern industrial applications? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE used for gaskets? Superior Sealing for Harsh Chemical & Temperature Environments