Due to its unique combination of properties, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer used across a vast range of demanding industries. Its applications are found in chemical processing, aerospace, automotive, medical, pharmaceutical, electrical, food and beverage, and power generation sectors where standard materials would fail.

PTFE's versatility is not derived from a single trait, but from its rare ability to simultaneously resist aggressive chemicals, withstand extreme temperatures, provide excellent electrical insulation, and offer an exceptionally low-friction surface.

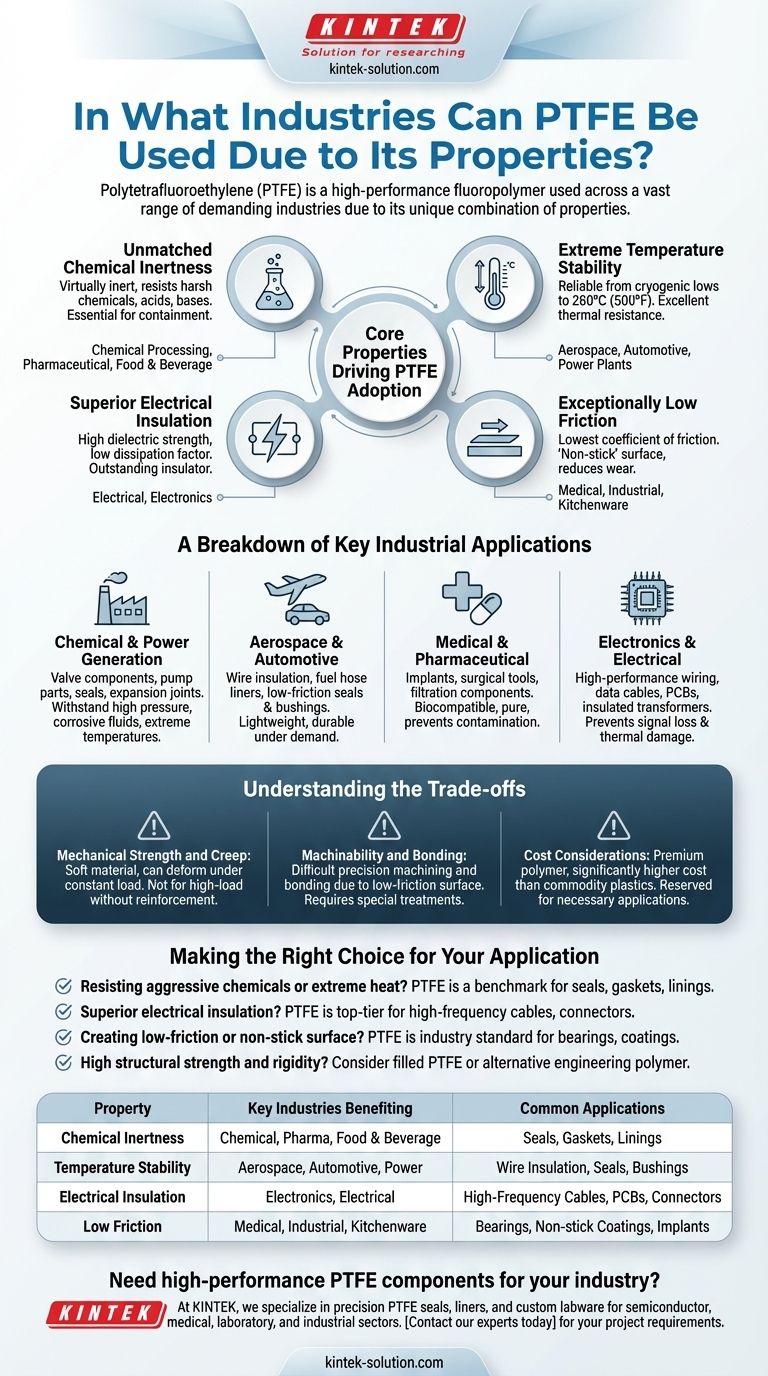

The Core Properties Driving PTFE Adoption

The widespread use of PTFE is a direct result of four key performance characteristics that make it a premier problem-solving material.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, acids, and bases. This makes it an essential material for containing and transporting corrosive substances.

This property is critical in the chemical processing, pharmaceutical, and food and beverage industries for components like seals, gaskets, and linings that ensure purity and prevent degradation.

Extreme Temperature Stability

PTFE maintains its properties over a very wide temperature range, performing reliably in environments from cryogenic lows to highs of 260°C (500°F).

This thermal resistance is crucial for applications in aerospace, automotive, and power plants, where components are exposed to extreme operational heat or fluctuating temperatures.

Superior Electrical Insulation

PTFE possesses a high dielectric strength and a low dissipation factor, making it an outstanding electrical insulator, especially for high-frequency applications.

This is why it is heavily utilized in the electrical and electronics industries for wire and cable insulation, printed circuit boards (PCBs), and connectors.

Exceptionally Low Friction

Known commercially as Teflon, PTFE has one of the lowest coefficients of friction of any solid material. This creates a "non-stick" surface that reduces wear and energy consumption in moving parts.

This property is vital for mechanical applications like bearings and pump parts, as well as for non-stick coatings in kitchenware and preventing biofouling on medical devices.

A Breakdown of Key Industrial Applications

Understanding how these properties solve specific industry challenges reveals why PTFE is so indispensable.

In Chemical and Power Generation

In these harsh environments, PTFE is fabricated into valve components, pump parts, seals, and expansion joints. It provides a reliable seal that can withstand high-pressure steam, corrosive fluids, and extreme process temperatures without failing.

In Aerospace and Automotive

The combination of light weight, temperature stability, and fluid resistance makes PTFE ideal for aerospace and automotive use. It is found in wire insulation, fuel hose liners, and low-friction seals and bushings that must perform reliably under demanding conditions.

In Medical and Pharmaceutical

Because it is both chemically inert and biocompatible, PTFE can be used for medical implants, surgical tools, and filtration components. Its purity is vital for manufacturing processes in the pharmaceutical industry where contamination is not an option.

In Electronics and Electrical

For high-performance wiring and data cables, PTFE insulation prevents signal loss and protects against thermal damage. Its use in PCBs and insulated transformers is fundamental to modern electronics.

Understanding the Trade-offs

While highly capable, PTFE is not a universal solution. Its selection requires an understanding of its inherent limitations.

Mechanical Strength and Creep

PTFE is a relatively soft material. Under a constant load, especially at elevated temperatures, it can deform over time in a process known as creep. It is not suitable for high-load structural applications without reinforcement (e.g., glass or carbon-filled grades).

Machinability and Bonding

Its softness can make precision machining a challenge. Furthermore, PTFE's low-friction, anti-stick surface makes it notoriously difficult to bond to other materials using conventional adhesives. Special surface treatments are often required.

Cost Considerations

PTFE is a premium, high-performance polymer. Its cost is significantly higher than that of commodity plastics like polyethylene or polypropylene, making it an investment reserved for applications where its unique properties are a necessity.

Making the Right Choice for Your Application

Selecting the right material depends entirely on your primary engineering challenge.

- If your primary focus is resisting aggressive chemicals or extreme heat: PTFE is a benchmark material for seals, gaskets, and linings in corrosive or high-temperature systems.

- If your primary focus is superior electrical insulation: PTFE is a top-tier choice for high-frequency cables, connectors, and insulating components where signal integrity is paramount.

- If your primary focus is creating a low-friction or non-stick surface: PTFE is the industry standard for low-wear bearings, self-lubricating parts, and release coatings.

- If your primary focus is high structural strength and rigidity: A standard PTFE is likely unsuitable; consider a filled PTFE grade or an alternative engineering polymer.

Ultimately, PTFE should be viewed as a specialized material engineered to solve problems that other plastics simply cannot handle.

Summary Table:

| Property | Key Industries Benefiting | Common Applications |

|---|---|---|

| Chemical Inertness | Chemical, Pharmaceutical, Food & Beverage | Seals, Gaskets, Linings |

| Temperature Stability | Aerospace, Automotive, Power Generation | Wire Insulation, Seals, Bushings |

| Electrical Insulation | Electronics, Electrical | High-Frequency Cables, PCBs, Connectors |

| Low Friction | Medical, Industrial, Kitchenware | Bearings, Non-stick Coatings, Implants |

Need high-performance PTFE components for your industry?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our custom fabrication expertise ensures you get components that leverage PTFE's full potential to solve your specific application challenges.

Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the temperature range for PTFE usage? Master -200°C to +260°C for Extreme Applications

- How does PTFE's molecular neutrality affect its properties? Unlock Unmatched Chemical and Electrical Performance

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- What are the advantages of polyamide fillers in PTFE? Protect Soft Mating Surfaces with Non-Abrasive Performance

- What is Teflon/PTFE and what are its key characteristics? Unlock the Power of a High-Performance Polymer

- What factors can cause variations in the actual properties of PTFE? Don't Rely on Generic Data Sheets

- What automotive application benefits from PTFE coating? Enhance Vehicle Reliability and Performance

- What are the safety considerations when using PTFE at high temperatures? Managing Decomposition Risks