At its core, Polytetrafluoroethylene's (PTFE) defining properties are a direct consequence of its molecular neutrality and unique electronic balance. This structure creates an exceptionally stable and non-reactive material, resulting in its signature chemical resistance, electrical inertness, and low-friction surface.

The key takeaway is that the tightly packed, electronegative fluorine atoms form a perfect, non-polar shield around the polymer's carbon backbone. This "fluorine sheath" is the source of PTFE's neutrality, physically and electronically isolating the molecule from its surrounding environment.

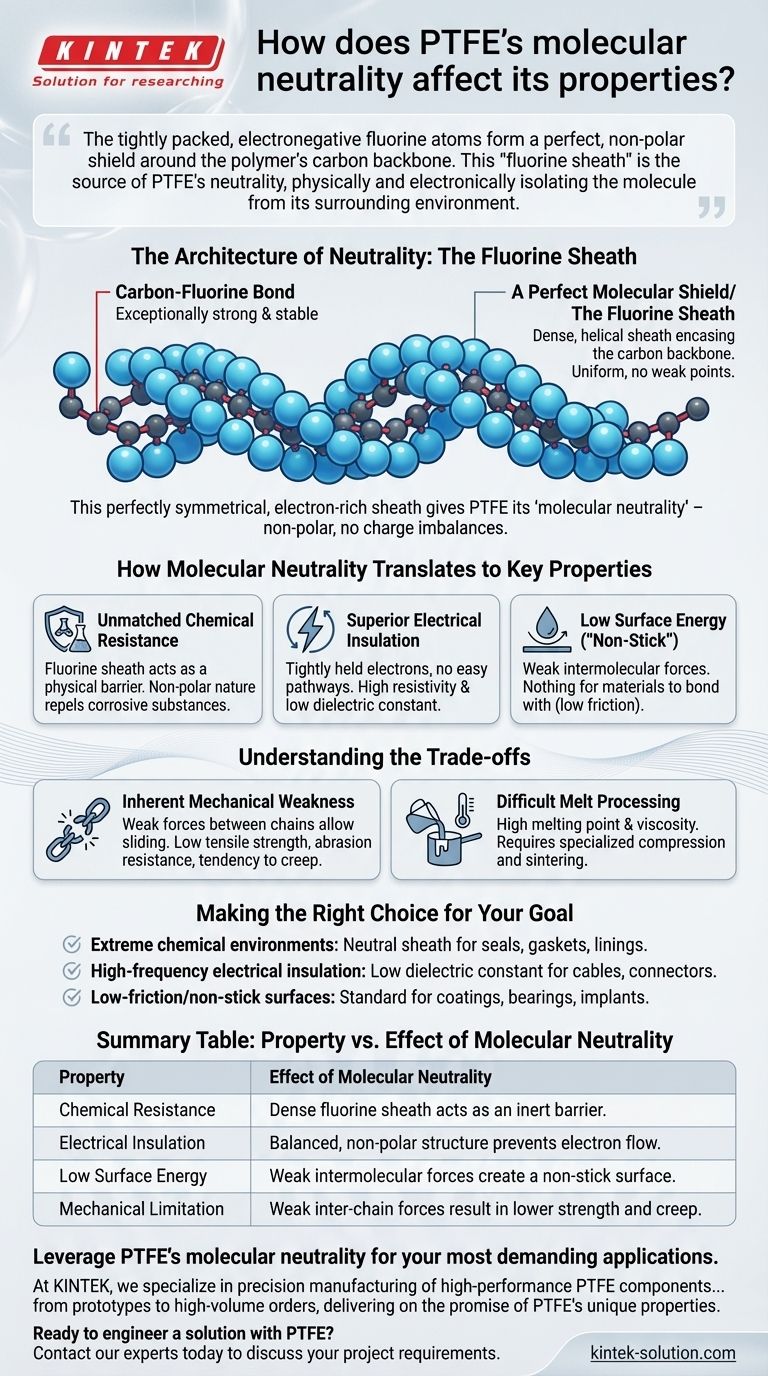

The Architecture of Neutrality: The Fluorine Sheath

The source of PTFE’s performance is not a complex additive package but the simple, brute-force elegance of its molecular architecture. It is designed for stability from the atom up.

The Carbon-Fluorine Bond

PTFE is a fluoropolymer, consisting of a long chain of carbon atoms bonded with fluorine atoms. The bond between carbon and fluorine is exceptionally strong and stable.

A Perfect Molecular Shield

The fluorine atoms are significantly larger than the carbon atoms they are bonded to. They arrange themselves in a tight, helical sheath that completely encases the vulnerable carbon-carbon backbone.

This uniform fluorine sheath leaves no weak points or gaps. It creates a molecule that is smooth and regular on an atomic level, with no significant charge imbalances across its surface.

The Resulting Electronic Balance

This perfectly symmetrical, electron-rich sheath is what gives PTFE its "molecular neutrality." The molecule is non-polar, meaning it has no positive or negative poles to attract other polar molecules.

How Molecular Neutrality Translates to Key Properties

This simple, stable, and neutral structure is directly responsible for the three properties that make PTFE so valuable in demanding industrial and technical applications.

Unmatched Chemical Resistance

Because the fluorine sheath is so dense and stable, it acts as a physical barrier. Corrosive chemicals cannot penetrate the shield to attack the carbon backbone.

Furthermore, the molecule's non-polar nature means it has very weak forces of attraction with other substances, preventing them from reacting with its surface.

Superior Electrical Insulation

An electrical current requires the movement of electrons. The fluorine atoms hold their electrons very tightly, and the balanced, neutral structure provides no free electrons or easy pathways for them to travel.

This results in an extremely high volume and surface resistance, making it one of the best electrical insulators known. Its low dielectric constant means it can insulate high-frequency signals with minimal loss.

Low Surface Energy (The "Non-Stick" Effect)

The same weak intermolecular forces that repel chemicals also repel almost everything else. There is simply nothing on the smooth, neutral surface for other materials—like water, oil, or adhesives—to "grab onto."

This inability to form bonds with other substances is the source of PTFE's famously low coefficient of friction and its non-stick character.

Understanding the Trade-offs

No material is perfect, and the very properties that make PTFE exceptional in some areas create limitations in others. Understanding this is critical for proper application.

Inherent Mechanical Weakness

The same weak intermolecular forces that make the surface non-stick also apply between the PTFE polymer chains themselves. The chains slide past each other easily.

This results in relatively poor mechanical properties, such as low tensile strength, low abrasion resistance, and a tendency to deform under load, a phenomenon known as creep or cold flow.

Difficult Melt Processing

The strong carbon-fluorine bonds and stable molecular structure give PTFE a very high melting point and an extremely high melt viscosity.

This makes it impossible to process using conventional techniques like injection molding. Instead, it requires specialized compression and sintering processes, similar to those used in powder metallurgy.

Making the Right Choice for Your Goal

By connecting PTFE's core molecular structure to its real-world performance, you can specify it with confidence.

- If your primary focus is extreme chemical environments: PTFE's neutral fluorine sheath provides the ultimate inert barrier for seals, gaskets, and chemical tank linings.

- If your primary focus is high-frequency electrical insulation: Its low dielectric constant and high resistivity, born from its electronic balance, are ideal for coaxial cables, connectors, and high-performance circuit boards.

- If your primary focus is low-friction or non-stick surfaces: The molecule's inability to form bonds makes it the standard for high-performance coatings, self-lubricating bearings, and medical implants.

Understanding this direct link between molecular neutrality and material performance is the key to deploying PTFE effectively in your most demanding applications.

Summary Table:

| Property | Effect of Molecular Neutrality |

|---|---|

| Chemical Resistance | Dense fluorine sheath acts as an inert barrier, repelling corrosive substances. |

| Electrical Insulation | Balanced, non-polar structure prevents electron flow, ensuring high resistivity. |

| Low Surface Energy | Weak intermolecular forces create a non-stick surface with a low coefficient of friction. |

| Mechanical Limitation | Weak inter-chain forces result in lower tensile strength and a tendency to creep. |

Leverage PTFE's molecular neutrality for your most demanding applications.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get components that deliver on the promise of PTFE's unique properties: ultimate chemical inertness, superior electrical insulation, and reliable non-stick performance.

Ready to engineer a solution with PTFE? Contact our experts today to discuss your project requirements and how we can bring value to your specialized application.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are the primary applications of PTFE? Unlocking High-Performance Solutions