In the automotive world, PTFE coatings are most commonly found on components requiring extremely low friction, chemical inertness, and high durability. Key applications include windshield wiper blades for a smooth glide, as well as a vast array of critical seals and gaskets within the engine, transmission, and fuel systems.

At its core, Polytetrafluoroethylene (PTFE) is not just a single-use material but a versatile engineering solution. Its value comes from a unique combination of properties—near-zero friction, high heat tolerance, and chemical immunity—that solve critical challenges of wear, efficiency, and reliability in the demanding automotive environment.

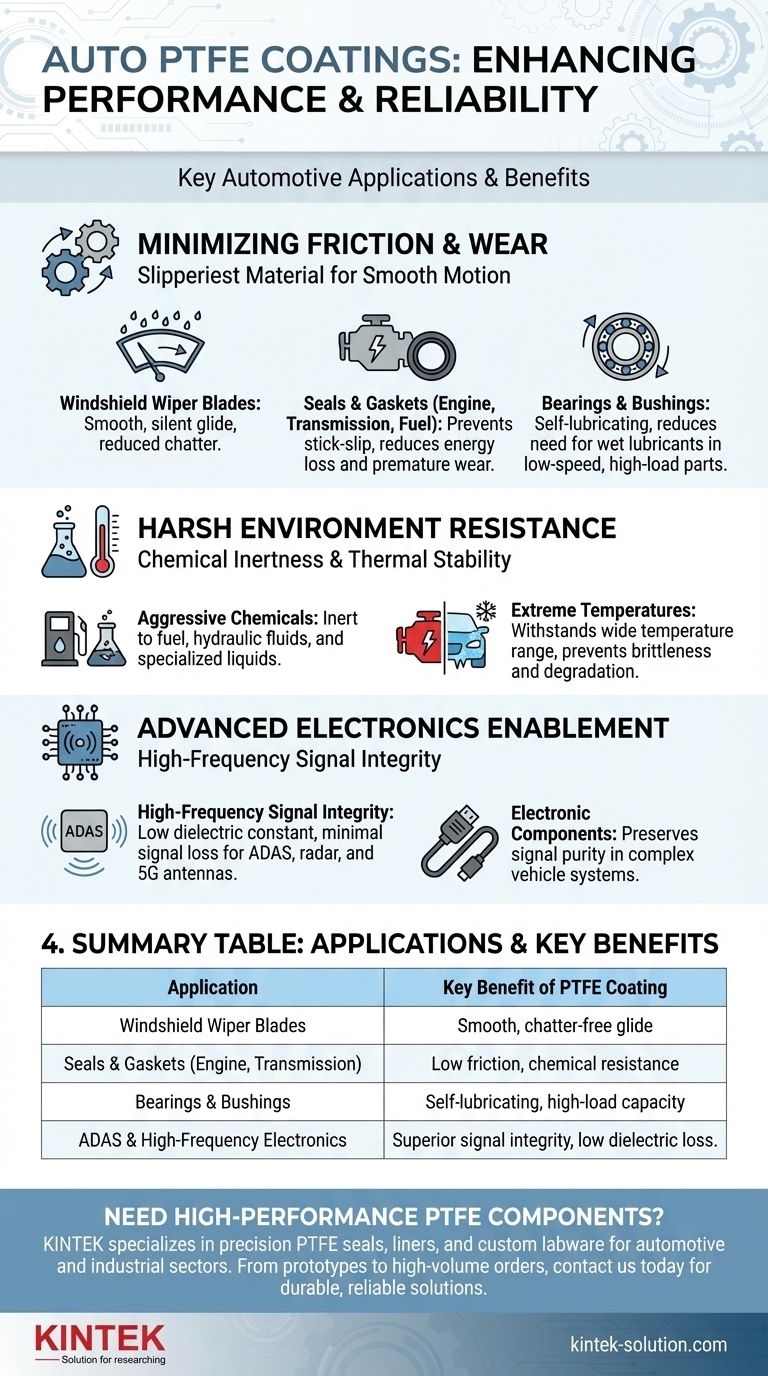

The Core Benefit: Minimizing Friction and Wear

The most recognized characteristic of PTFE is its extremely low coefficient of friction, making it one of the slipperiest materials known. This property is foundational to its use in parts that slide or rotate.

Windshield Wiper Blades

A PTFE coating on wiper blades is a classic example of its benefit. The slick surface allows the blade to glide effortlessly and silently across the windshield, reducing chatter and ensuring a smooth, clean wipe in all conditions.

Seals and Gaskets

PTFE is a premier material for dynamic seals, which are used on moving or rotating parts. It prevents the "stick-slip" phenomenon, reducing energy loss and preventing premature wear on components like shafts and housings.

You will find PTFE seals in critical systems such as:

- Fuel injection pumps

- Gearboxes and transmissions

- Air conditioning compressors

- Hydraulic and power steering systems

Bearings and Bushings

For low-speed, high-load applications, PTFE-coated bearings and bushings offer a self-lubricating surface. This reduces the need for wet lubricants, simplifies design, and enhances the longevity of suspension components and other moving parts.

Excelling in Harsh Chemical and Thermal Environments

An automobile is a hostile environment, filled with corrosive fluids and extreme temperature swings. PTFE's inherent stability makes it an ideal choice for protecting components.

Resisting Aggressive Chemicals

PTFE is almost completely inert, meaning it does not react with most chemicals. This makes it essential for seals and gaskets in the fuel system, where it is constantly exposed to gasoline or diesel, and in hydraulic systems containing specialized fluids.

Tolerating Extreme Temperatures

From the heat of the engine block to the cold of a winter start, automotive parts must maintain their integrity. PTFE withstands a very wide temperature range, ensuring that seals and gaskets do not become brittle or degrade under thermal stress.

Preventing Blow-Out in High-Pressure Systems

In applications like engine head gaskets or flanges in the exhaust system, pressure containment is critical. When combined with fillers, PTFE gaskets offer superior "blow-out resistance," maintaining a secure seal under high pressure and temperature.

Enabling Advanced Automotive Electronics

Modern vehicles are complex electronic systems. As data speeds increase for features like advanced driver-assistance systems (ADAS) and in-car connectivity, signal integrity becomes paramount.

High-Frequency Signal Integrity

PTFE has an exceptionally low dielectric constant and low signal loss. This means it acts as a near-perfect insulator for high-frequency electrical signals, allowing them to travel through circuit boards and cables with minimal degradation or delay.

Applications in ADAS and Connectivity

This electrical property makes PTFE laminates a critical material for high-frequency systems. They are used in the construction of radar sensors, 5G antennas, and other communication modules where preserving signal purity is essential for performance and safety.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. Understanding its limitations is key to using it effectively.

The Role of Fillers

Pure, or "virgin," PTFE can be relatively soft and prone to creep under load. To enhance its mechanical properties, it is often blended with fillers like glass, carbon, or bronze. These fillers dramatically improve wear resistance and compressive strength but may slightly alter its coefficient of friction or chemical resistance profile.

Application and Bonding Challenges

PTFE is famously non-stick, which makes bonding it to other materials a highly specialized industrial process. A PTFE coating is not something that can be simply painted on; it requires precise surface preparation and curing to ensure a durable bond.

Cost vs. Performance

PTFE is a premium performance material, and its cost reflects that. Its use is therefore justified in applications where standard elastomers or plastics would fail and where its unique combination of properties provides a clear reliability or performance advantage.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on the primary problem you need to solve.

- If your primary focus is reducing friction and mechanical wear: PTFE is the industry standard for dynamic seals, low-friction bearings, and sliding surfaces that demand smooth, reliable motion.

- If your primary focus is durability against heat and chemicals: PTFE gaskets and seals provide unmatched reliability in fuel systems, transmissions, and engine components exposed to aggressive fluids and high temperatures.

- If your primary focus is maintaining signal integrity in high-frequency electronics: PTFE-based laminates are the superior choice for building radar modules, antennas, and other advanced sensors where minimal signal loss is critical.

Ultimately, leveraging PTFE effectively means matching its unique properties to a specific engineering challenge, ensuring a more reliable and higher-performing component.

Summary Table:

| Application | Key Benefit of PTFE Coating |

|---|---|

| Windshield Wiper Blades | Smooth, chatter-free glide |

| Seals & Gaskets (Engine, Transmission) | Low friction, chemical resistance |

| Bearings & Bushings | Self-lubricating, high-load capacity |

| ADAS & High-Frequency Electronics | Superior signal integrity, low dielectric loss |

Need high-performance PTFE components for your automotive application? KINTEK specializes in manufacturing precision PTFE seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your components meet rigorous standards for durability, chemical resistance, and reliability. Contact us today to discuss how our PTFE solutions can enhance your product's performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability