In the healthcare industry, Teflon (PTFE) sheets are primarily utilized for their unique combination of biocompatibility, chemical inertness, and extremely low friction. These properties make them ideal for coating medical devices like catheters and surgical instruments, which helps to reduce infection rates, prevent adverse reactions with body tissue, and improve patient comfort during procedures.

The core value of Teflon in medicine is its ability to create a safe, non-reactive, and non-stick barrier. This barrier is critical for improving the safety of invasive devices, ensuring the purity of pharmaceuticals, and enhancing the performance of surgical tools.

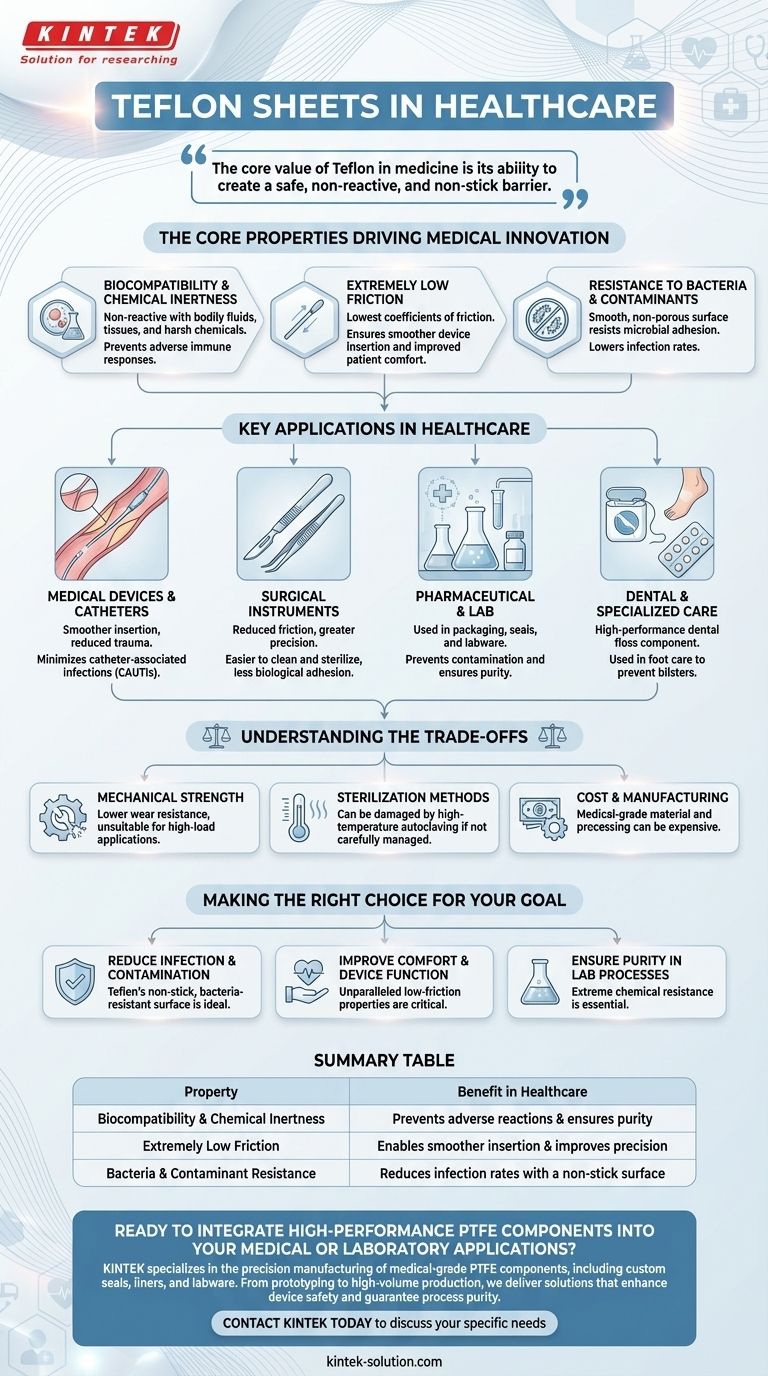

The Core Properties Driving Medical Innovation

To understand Teflon's role in healthcare, you must first understand the fundamental material properties that make it so valuable. Its application isn't arbitrary; it's a direct result of its unique molecular structure.

Biocompatibility and Chemical Inertness

Teflon is exceptionally non-reactive. It does not react with bodily fluids, tissues, or the aggressive chemicals used during sterilization processes.

This inertness is critical for preventing contamination and ensuring that implanted devices or surgical tools do not cause an adverse immune response in the patient.

Extremely Low Friction

Known for its "non-stick" surface, Teflon has one of the lowest coefficients of friction of any solid material.

This lubricity is essential for devices like catheters, which can be inserted more smoothly and with less trauma to the patient. It also allows moving parts in medical equipment to function without traditional lubricants that could become contaminants.

Resistance to Bacteria and Contaminants

The smooth, non-porous surface of Teflon makes it difficult for bacteria and other microbes to adhere.

This property directly contributes to lower infection rates. Furthermore, antimicrobial agents can be incorporated into Teflon coatings to create an actively sterile surface on medical devices.

Key Applications in Healthcare

These core properties translate into several critical applications across the medical and pharmaceutical sectors.

Medical Devices and Catheters

Catheters coated with Teflon are smoother, making insertion easier and more comfortable for the patient. The coating also provides a bacteria-resistant surface, which is crucial for reducing the risk of catheter-associated urinary tract infections (CAUTIs).

Surgical Instruments and Equipment

A thin coating of Teflon on surgical instruments reduces friction, making them more precise during procedures. It also makes them easier to clean and sterilize, as biological matter is less likely to stick to the surface.

Pharmaceutical and Laboratory Settings

Due to its chemical resistance, Teflon is used for pharmaceutical packaging, seals, and lab equipment like beakers and stirring bars. It ensures that sensitive chemical compounds and medicines are not contaminated by reacting with their containers.

Dental and Specialized Care

Teflon's versatility extends to specialized fields. It is used in certain dental fillings and is the primary component of high-performance dental floss. Its low-friction properties are also leveraged in some foot care products to prevent blisters.

Understanding the Trade-offs

While highly effective, Teflon is not a universal solution. It's important to recognize its limitations to apply it correctly.

Mechanical Strength

Teflon is a relatively soft material with lower wear resistance compared to metals or harder polymers. This makes it unsuitable for high-load, high-wear applications such as the primary surfaces of artificial joints.

Sterilization Methods

While resistant to many chemical sterilizers, Teflon can be damaged by certain high-temperature sterilization methods like autoclaving if not managed properly. This requires careful consideration of the sterilization protocols for any device that incorporates it.

Cost and Manufacturing

High-quality, medical-grade Teflon and the processes required to apply it as a coating or machine it into precise components can be more expensive than other conventional materials, impacting the final cost of a medical device.

Making the Right Choice for Your Goal

Selecting the right material is about matching its properties to the primary objective of the medical application.

- If your primary focus is reducing infection and contamination: Teflon's non-stick, bacteria-resistant, and inert surface is the ideal choice for device coatings and pharmaceutical packaging.

- If your primary focus is improving patient comfort and device function: Its unparalleled low-friction properties are critical for catheters, guide wires, and surgical tools that interact with sensitive tissues.

- If your primary focus is ensuring purity in lab processes: Its extreme chemical resistance makes it essential for labware and containers where sample or product integrity is the highest priority.

Ultimately, Teflon's unique material science has made it an indispensable tool for engineering safer and more effective healthcare solutions.

Summary Table:

| Property | Benefit in Healthcare |

|---|---|

| Biocompatibility & Chemical Inertness | Prevents adverse reactions with body tissue and ensures purity in pharmaceuticals. |

| Extremely Low Friction | Enables smoother insertion of catheters and improves precision of surgical tools. |

| Bacteria & Contaminant Resistance | Reduces infection rates by creating a non-stick, non-porous surface. |

Ready to integrate high-performance PTFE components into your medical or laboratory applications?

KINTEK specializes in the precision manufacturing of medical-grade PTFE components, including custom seals, liners, and labware. Our expertise ensures the material integrity and biocompatibility required for the semiconductor, medical, and laboratory industries. From prototyping to high-volume production, we deliver solutions that enhance device safety, improve patient comfort, and guarantee process purity.

Contact KINTEK today to discuss your specific needs and discover how our custom PTFE fabrication can benefit your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the properties and applications of reinforced PTFE compounds? Enhance Performance with Engineered Materials

- Why is Teflon difficult to machine to tight tolerances? Overcome Material Instability

- What are the mechanical properties of PTFE balls? Leverage Low Friction & Chemical Resistance

- What are the key benefits of using PTFE lined valves in chemical plants? Boost Safety and Cut Costs

- What are the key properties of PTFE envelope gaskets? Ensure Reliable Sealing in Demanding Environments

- What materials are offered for PTFE bushes? Choose the Right Filled PTFE Compound for Your Application

- What are the benefits of PTFE packing in various industries? Enhance Sealing Performance & Reliability

- How are Teflon sheets used in embroidery? Achieve Professional Results with a Simple Tool