In professional embroidery, a Teflon sheet is an indispensable tool for heat application. It primarily serves two critical functions: acting as a protective heat shield for your project and as a non-stick barrier that prevents adhesives and other residues from contaminating your equipment. This simple accessory ensures a clean, professional finish every time.

The true value of a Teflon sheet isn't just about protection; it's about control. It creates an essential barrier between your heat source, your delicate fabric, and any adhesives, preventing scorching, unwanted shine, and sticky messes that can ruin a project.

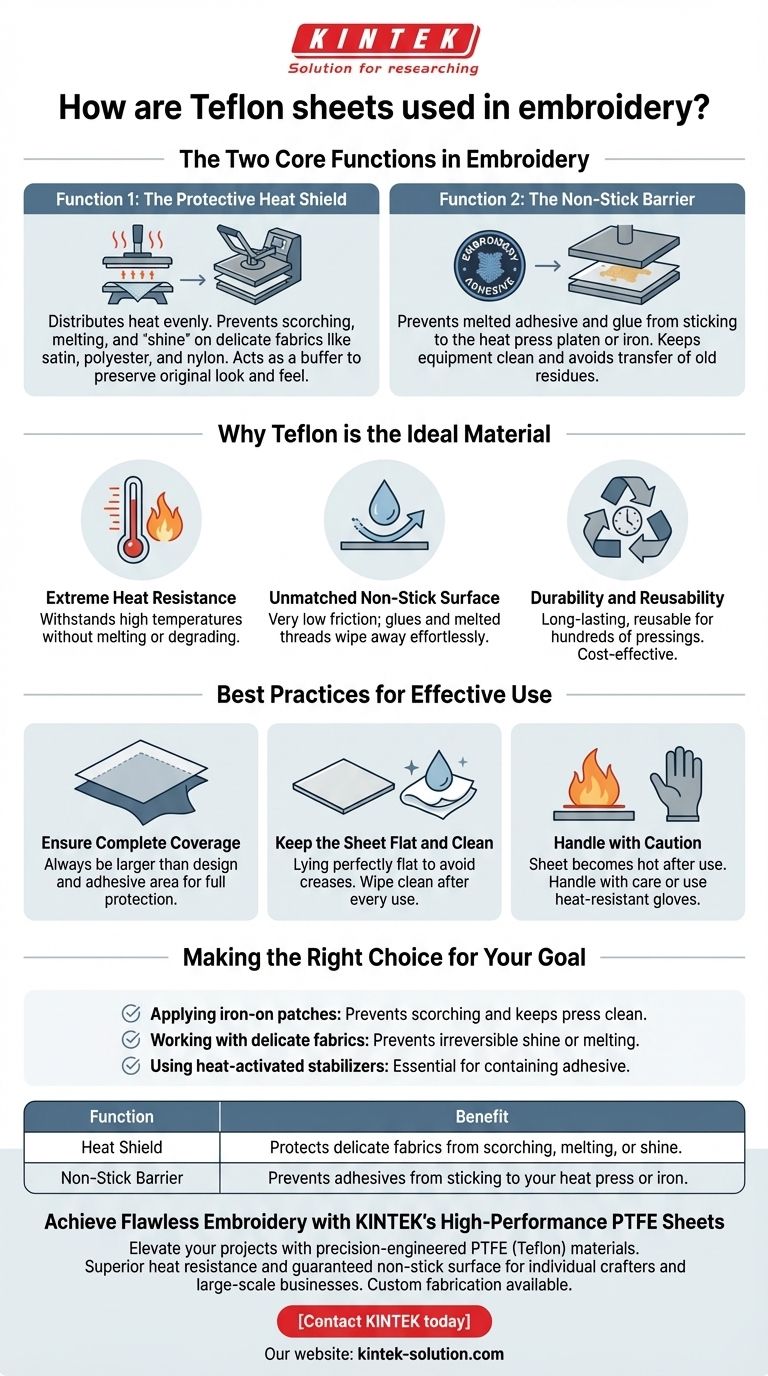

The Two Core Functions in Embroidery

Understanding how a Teflon sheet works reveals why it is a non-negotiable tool for anyone using a heat press or iron with their embroidery projects.

Function 1: The Protective Heat Shield

Many embroidery processes, such as applying patches or using heat-activated stabilizers, require high temperatures.

Direct contact from a heat press or iron can easily damage delicate fabrics. Materials like satin, polyester, or nylon are prone to scorching, melting, or developing an undesirable "shine" under intense, direct heat.

A Teflon sheet acts as a buffer, distributing the heat evenly across the surface of the garment. This prevents direct contact and shields the fabric fibers from damage, preserving the material's original look and feel.

Function 2: The Non-Stick Barrier

Embroidery often involves adhesives, from temporary spray tack to permanent, heat-activated backings like Heat-N-Bond.

When heated, these adhesives can liquefy and ooze from the edges of your design or patch. Without a barrier, this melted glue transfers directly onto the hot surface of your heat press platen or iron.

The non-stick property of Teflon, famous for its use in cookware, prevents this. Any excess adhesive sticks to the sheet, not your equipment. This keeps your press clean and prevents old, discolored glue from being accidentally transferred to your next project.

Why Teflon is the Ideal Material

Teflon's unique properties, developed for demanding industrial and aerospace applications, make it perfectly suited for the embroidery studio.

Extreme Heat Resistance

Teflon is engineered to withstand incredibly high temperatures without degrading. The heat generated by a standard craft press is well within its safe operating range, ensuring it will not melt, burn, or release fumes.

Unmatched Non-Stick Surface

The material has one of the lowest coefficients of friction known, meaning very few substances will stick to it. This is why it's used for everything from non-stick pans to industrial seals. For embroidery, it means glues and melted synthetic threads wipe away effortlessly.

Durability and Reusability

A high-quality Teflon sheet is not a disposable item. It is a durable, long-lasting tool that can be wiped clean and reused for hundreds or even thousands of pressings, making it a highly cost-effective investment.

Best Practices for Effective Use

Using a Teflon sheet correctly is simple but crucial for achieving the best results and avoiding common mistakes.

Ensure Complete Coverage

Your Teflon sheet should always be larger than the design and any adhesive area. This guarantees that both your garment and your heat press platen are fully protected from contact.

Keep the Sheet Flat and Clean

A wrinkle or fold in the Teflon sheet can press a permanent crease into your fabric. Always ensure the sheet is lying perfectly flat before applying heat.

Furthermore, wipe the sheet clean after every use. Any adhesive residue left on the sheet can easily be transferred to the next garment you press.

Handle with Caution

Remember that the sheet absorbs and holds heat. After pressing, it will be extremely hot to the touch. Always handle it with care or use heat-resistant gloves to move it.

Making the Right Choice for Your Goal

Integrate a Teflon sheet into your workflow to solve specific, common embroidery challenges.

- If your primary focus is applying iron-on patches: Always use a Teflon sheet to prevent scorching the patch or garment while keeping your press free of melted adhesive.

- If your primary focus is working with delicate fabrics like satin or performance wear: Use a Teflon sheet as a mandatory heat shield to prevent irreversible shine or melting.

- If your primary focus is using any form of heat-activated stabilizer or backing: A Teflon sheet is essential for containing adhesive and ensuring a clean, easy release from your press.

Ultimately, a Teflon sheet is a simple, inexpensive form of insurance that guarantees a clean, professional outcome for every heat-related embroidery task.

Summary Table:

| Function | Benefit |

|---|---|

| Heat Shield | Protects delicate fabrics from scorching, melting, or shine. |

| Non-Stick Barrier | Prevents adhesives from sticking to your heat press or iron. |

Achieve Flawless Embroidery with KINTEK's High-Performance PTFE Sheets

Elevate your embroidery projects with the same precision-engineered PTFE (Teflon) materials trusted by the semiconductor and medical industries. KINTEK manufactures durable, reusable PTFE sheets that provide superior heat resistance and a guaranteed non-stick surface, protecting your delicate fabrics and expensive equipment.

Whether you're an individual crafter or a large-scale embroidery business, we offer custom fabrication from prototypes to high-volume orders to meet your exact needs.

Contact KINTEK today to discuss your requirements and ensure a professional finish on every project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments