At its core, PTFE packing is a premier sealing solution valued across industries for its exceptional chemical resistance, stability across a wide range of temperatures, and extremely low friction. These properties make it the material of choice for sealing pumps, valves, and other mechanical equipment in some of the most demanding operational environments imaginable.

The primary benefit of PTFE packing is its unique combination of chemical inertness and mechanical lubricity. This allows it to create a reliable, long-lasting seal that protects both the equipment from wear and the processed product from contamination.

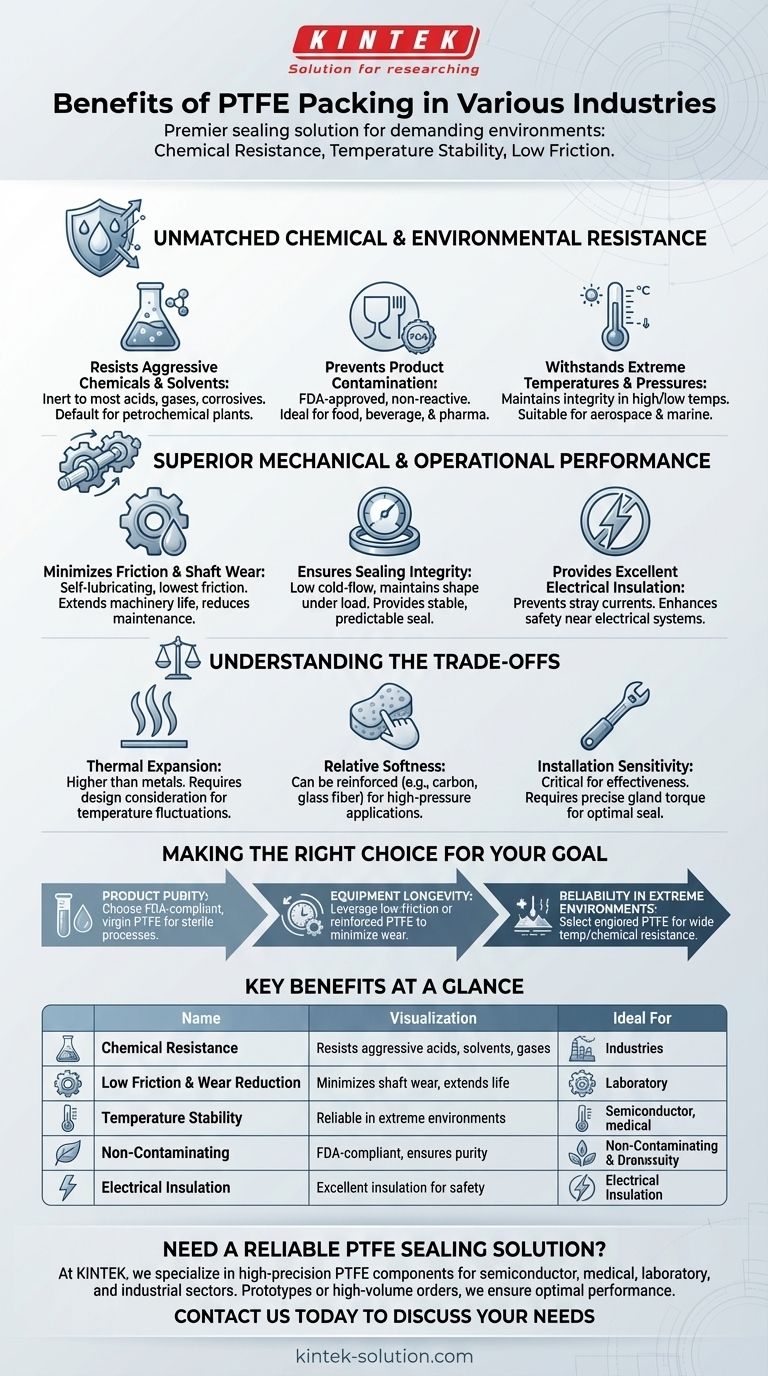

Unmatched Chemical and Environmental Resistance

One of the most significant advantages of Polytetrafluoroethylene (PTFE) is its ability to withstand hostile environments without degrading. This resilience is critical for both safety and operational uptime.

Resists Aggressive Chemicals and Solvents

PTFE is virtually inert to most industrial chemicals, acids, gases, and corrosive substances. This makes it a default choice for equipment in petrochemical plants and chemical processing facilities handling aggressive media.

Prevents Product Contamination

Because PTFE packing is a non-reactive polymer that does not bleed color or leach materials, it is ideal for sensitive applications. It is often FDA-approved, making it a staple in the food, beverage, and pharmaceutical industries where product purity is non-negotiable.

Withstands Extreme Temperatures and Pressures

PTFE maintains its integrity in both high and low-temperature applications. This robustness makes it suitable for aerospace and marine equipment, which must perform reliably under extreme pressure and in corrosive saltwater environments.

Superior Mechanical and Operational Performance

Beyond its chemical resistance, the physical properties of PTFE packing directly contribute to better equipment performance and a longer operational lifespan.

Minimizes Friction and Shaft Wear

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property significantly reduces the wear and tear on rotating shafts and stems, extending the life of expensive machinery and minimizing maintenance costs.

Ensures Sealing Integrity

High-quality PTFE packing exhibits very low "cold-flow," or creep tendency. This means it maintains its shape and sealing pressure even under high mechanical loads, providing a more stable and predictable seal over time.

Provides Excellent Electrical Insulation

As a strong electrical insulator, PTFE is also valuable in applications where sealing components are near electrical systems. It helps prevent stray currents and enhances the safety of the equipment.

Understanding the Trade-offs

While highly effective, PTFE packing is not a universal solution. Understanding its limitations is key to successful implementation.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than many metals. This must be accounted for during design and installation, especially in systems with wide temperature fluctuations, to ensure a consistent seal.

Relative Softness

In its pure form, PTFE is a relatively soft material. For high-pressure applications, it is often reinforced with other materials like carbon or glass fiber to enhance its compressive strength and resistance to extrusion.

Installation Sensitivity

The effectiveness of any packing material is highly dependent on proper installation. The precise properties of PTFE demand careful attention to gland torque specifications to achieve an optimal seal without over-compressing the material.

Making the Right Choice for Your Goal

Selecting the correct packing material depends entirely on your primary operational objective.

- If your primary focus is product purity: Choose an FDA-compliant, non-contaminating virgin PTFE packing to ensure your process media in food, beverage, or pharmaceutical applications remains sterile.

- If your primary focus is equipment longevity: Leverage the low-friction properties of lubricated or reinforced PTFE packing to minimize shaft wear and reduce maintenance intervals in heavy industrial pumps and valves.

- If your primary focus is reliability in extreme environments: Select a grade of PTFE packing engineered for a wide temperature range and resistance to aggressive chemicals, ideal for aerospace, marine, or chemical processing.

By understanding these core benefits and considerations, you can confidently specify the right sealing solution to enhance both performance and reliability.

Summary Table:

| Key Benefit | Description | Ideal For |

|---|---|---|

| Chemical Resistance | Resists aggressive acids, solvents, and gases without degrading. | Chemical processing, petrochemical plants. |

| Low Friction & Wear Reduction | Self-lubricating properties minimize shaft wear and extend equipment life. | Pumps, valves, and rotating machinery. |

| Temperature Stability | Performs reliably in extreme high and low-temperature environments. | Aerospace, marine, and industrial applications. |

| Non-Contaminating | FDA-compliant; ensures product purity in sensitive processes. | Food, beverage, pharmaceutical industries. |

| Electrical Insulation | Provides excellent insulation for safety in electrical applications. | Equipment near electrical systems. |

Need a reliable PTFE sealing solution tailored to your industry? At KINTEK, we specialize in manufacturing high-precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures optimal performance, extended equipment life, and contamination-free operations. Contact us today to discuss your specific needs and let us enhance your application's reliability and efficiency!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What advantages do PTFE valves offer in terms of friction? Achieve Ultra-Low Friction and Energy Savings

- How are extruded PTFE rods used in the electrical/electronics industry? Ensure Superior Insulation and Reliability

- What makes PTFE seats suitable for demanding environments in butterfly valves? Unlock Chemical & Thermal Resilience

- What role do Teflon plastic sheets play in food processing? Solve Stickiness & Boost Efficiency

- What material properties make polymer-plastic ball bearings suitable for diverse industries? Solve Harsh Environment Challenges

- In what applications are PTFE Crimped designs commonly used? Sealing Solutions for Extreme Environments

- What are the key properties of PTFE guide strips? Ensure Low-Friction, High-Temp Performance

- What are the standard gasket choices for PTFE rotary lip seals? Ensure Total System Reliability