In electronics manufacturing, Teflon sheet is used as a high-performance electrical insulator and thermal barrier. Its primary roles are to provide a stable, non-conductive barrier between different parts of a circuit and to protect components from heat damage during both manufacturing and operation.

The core value of Teflon in electronics is not just its ability to insulate, but its unique combination of electrical, thermal, and chemical resistance. This makes it an essential material for creating custom, reliable components in demanding and high-stakes applications.

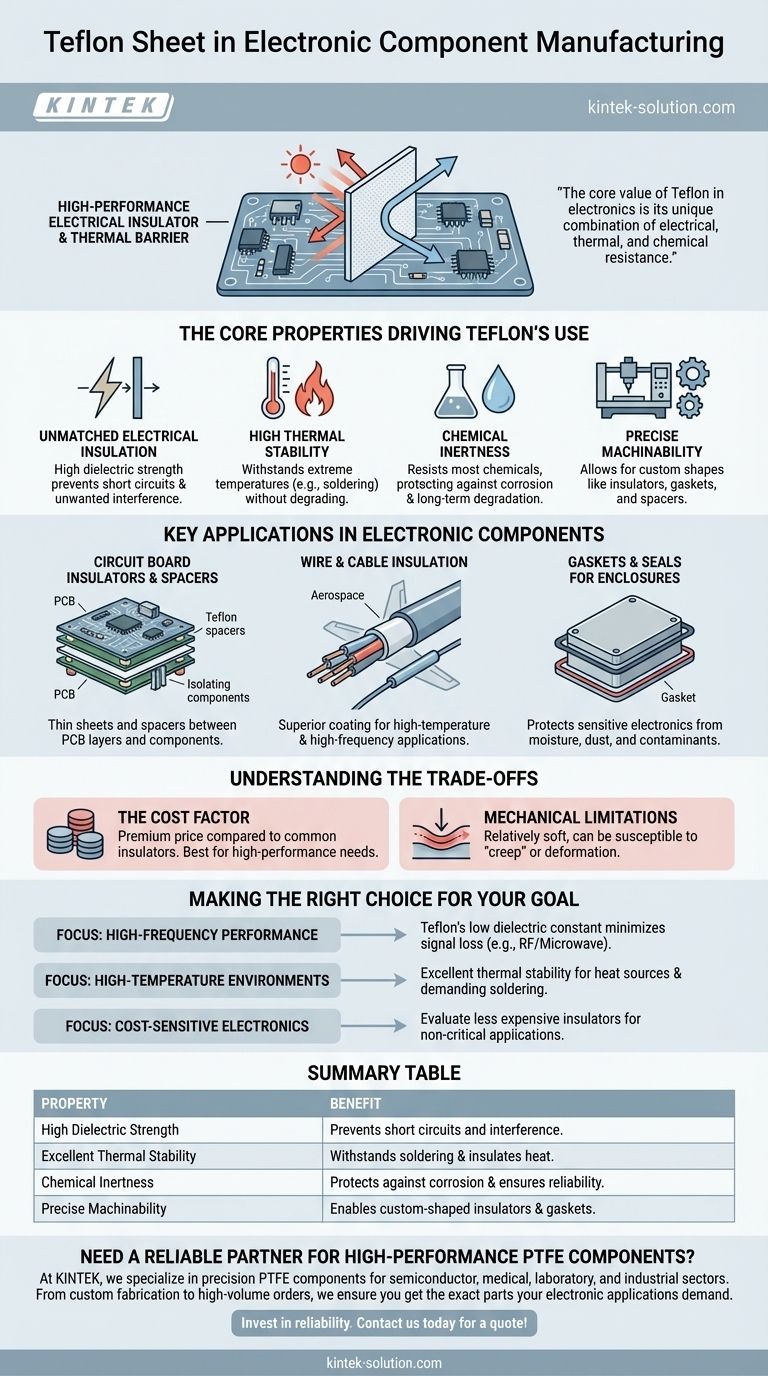

The Core Properties Driving Teflon's Use in Electronics

To understand why Teflon (PTFE) is so widely adopted, we must look at its fundamental material properties. These characteristics directly solve common challenges in electronic component design and assembly.

Unmatched Electrical Insulation

Teflon has an extremely high dielectric strength, meaning it is an excellent electrical insulator. This property is crucial for preventing short circuits and unwanted electrical interference between sensitive components on a circuit board.

High Thermal Stability

With a very high melting point, Teflon can withstand the extreme temperatures of manufacturing processes like soldering without degrading. It also reliably insulates components that generate significant heat during normal operation, ensuring stability.

Chemical Inertness

Teflon is almost completely inert, meaning it does not react with most chemicals. This ensures the long-term integrity and reliability of electronic components, protecting them from corrosion or degradation from environmental exposure.

Precise Machinability

Manufacturers can use advanced CNC equipment to machine Teflon sheets into highly precise and custom shapes. This allows for the creation of bespoke insulators, gaskets, and spacers that fit perfectly within complex electronic assemblies.

Key Applications in Electronic Component Manufacturing

These core properties translate into several critical applications where standard plastics or insulators would fail.

Circuit Board Insulators and Spacers

Teflon is machined into thin sheets or custom-shaped spacers that are placed between layers of a printed circuit board (PCB). They are also used to physically isolate individual components, preventing electrical contact.

Wire and Cable Insulation

As a coating or "jacket" for electrical wires, Teflon provides superior insulation, especially in high-temperature or high-frequency applications. This is common in aerospace and military-grade hardware where reliability is paramount.

Gaskets and Seals for Enclosures

Teflon's resistance to water and chemicals makes it an ideal material for gaskets and seals. These are used to protect sensitive electronics inside an enclosure from moisture, dust, and other contaminants.

Understanding the Trade-offs

While powerful, Teflon is not the solution for every scenario. Acknowledging its limitations is key to making an informed decision.

The Cost Factor

Teflon is a premium material and is significantly more expensive than common insulators like PVC or polyethylene. Its use is typically reserved for applications where its high-performance characteristics are a necessity.

Mechanical Limitations

The material is relatively soft and can be susceptible to "creep" or deforming under sustained pressure. This makes it less suitable for high-load structural applications compared to more rigid engineering plastics.

Making the Right Choice for Your Goal

Your specific goal will determine if Teflon is the appropriate material for your electronic component.

- If your primary focus is high-frequency performance: Teflon's low dielectric constant is critical for minimizing signal loss in RF and microwave circuits.

- If your primary focus is high-temperature environments: Its excellent thermal stability makes it a reliable choice for components near heat sources or those undergoing demanding soldering.

- If your primary focus is cost-sensitive consumer electronics: You will likely need to evaluate less expensive insulators, as Teflon's high performance comes at a premium price.

Ultimately, choosing Teflon is an investment in reliability and performance for electronic components where failure is not an option.

Summary Table:

| Property | Benefit in Electronics |

|---|---|

| High Dielectric Strength | Prevents short circuits and electrical interference. |

| Excellent Thermal Stability | Withstands soldering temperatures and insulates heat-generating parts. |

| Chemical Inertness | Protects against corrosion and ensures long-term reliability. |

| Precise Machinability | Enables custom-shaped insulators, spacers, and gaskets. |

Need a reliable partner for high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom sheets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get the exact Teflon parts your electronic applications demand.

Invest in reliability. Contact us today to discuss your project requirements and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the typical friction coefficient values for PTFE? A Guide to Low-Friction Performance

- What are the core materials used in TFE Encapsulated gaskets and their applications? A Guide to Superior Sealing

- What challenges are associated with machining PTFE? Overcoming Heat, Tolerances, and Safety

- What are the main disadvantages of virgin PTFE products in fluid sealing applications? Overcoming Creep and Cold Flow

- What industries benefit most from PTFE coatings? Unlock Superior Performance in Demanding Environments

- What are the main benefits of using PTFE liners? Achieve Unmatched Chemical and Thermal Resistance

- Why are PTFE seats preferred in electric actuated butterfly valves? Enhance Valve Performance and Actuator Lifespan

- What types of Teflon backup rings are available and their uses? Ensure Sealing Integrity in High-Pressure Systems