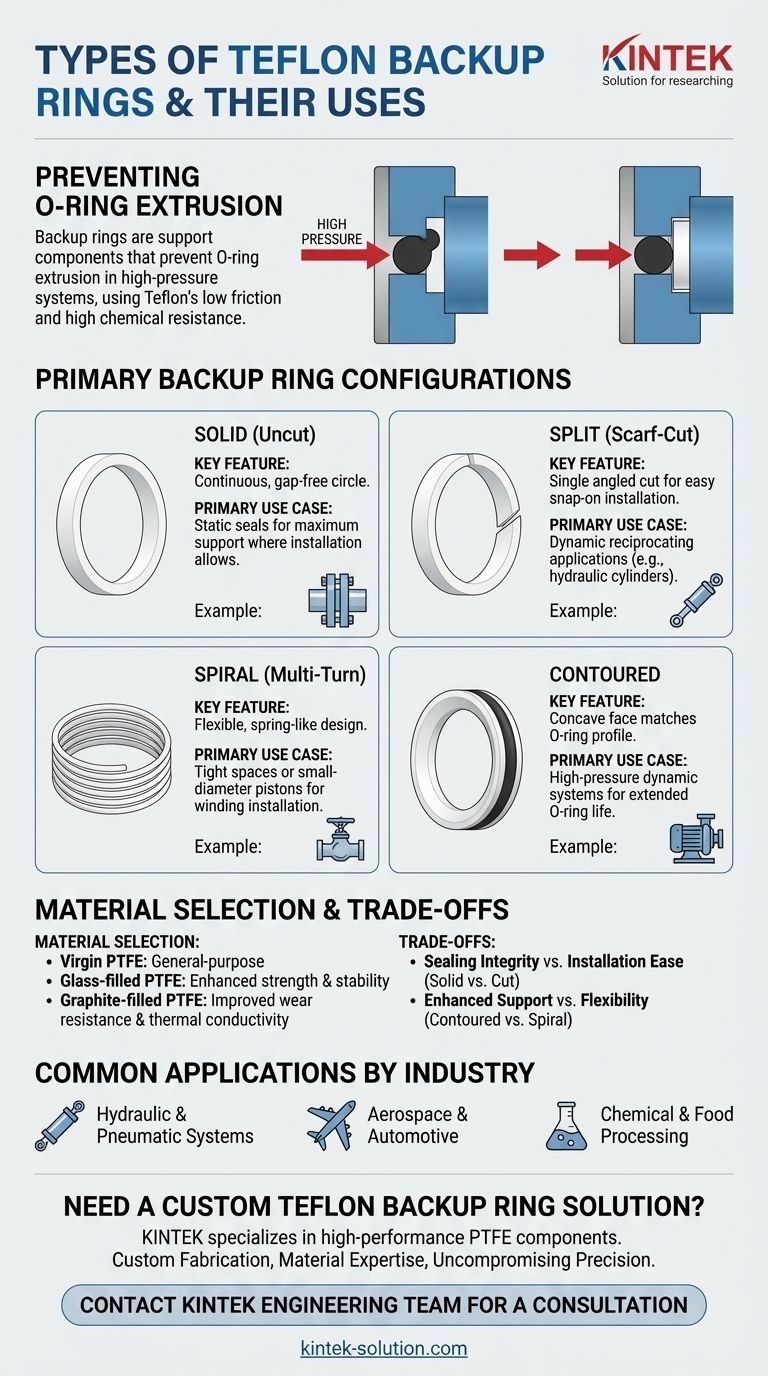

The primary types of Teflon backup rings are Solid (uncut), Split (scarf-cut), Spiral (multi-turn), and Contoured. Each is engineered to solve a specific installation or performance challenge, with the fundamental goal of preventing O-ring extrusion in high-pressure sealing applications. Their effectiveness stems from Teflon's unique properties of low friction and high chemical resistance, making them indispensable in demanding industrial environments.

The choice of a Teflon backup ring is a deliberate engineering decision dictated by the application's specific demands. You must balance the need for absolute sealing integrity against the practicalities of installation and the dynamic forces at play within the system.

The Fundamental Role of a Backup Ring

Before comparing types, it is critical to understand the problem they solve. Backup rings are not seals themselves; they are support components.

Preventing O-ring Extrusion

In high-pressure systems, the force can physically push, or extrude, a softer O-ring into the small gap between mating metal parts. This damages the O-ring, leading to seal failure and leaks.

A backup ring is a rigid, strong ring installed next to the O-ring. It sits on the low-pressure side, physically blocking the gap and providing a robust surface for the O-ring to press against, preventing extrusion.

Why Teflon (PTFE)?

Teflon, or Polytetrafluoroethylene (PTFE), is the material of choice for its unique combination of properties. It is nearly chemically inert, has an extremely low coefficient of friction, and operates across a wide temperature range. This makes it compatible with aggressive hydraulic fluids, chemicals, and demanding operating conditions.

A Profile of Each Ring Type

The four main configurations of Teflon backup rings are defined by their physical geometry, which directly relates to their installation method and ideal use case.

Solid (Uncut) Rings

The Solid ring is a continuous, unbroken circle. It offers the best possible support because it presents no seams or gaps for an O-ring to extrude through.

Its primary application is in static seals, where one of the components can be easily installed over the ring. Due to its rigidity, it cannot be snapped into place in a typical groove.

Split (Scarf-Cut) Rings

The Split ring is cut through at a single point, usually at an angle (a scarf cut). This cut allows the ring to be slightly opened and easily snapped over a shaft or into a groove.

This design is the most common for dynamic reciprocating applications, like hydraulic cylinders, where ease of assembly and maintenance is crucial.

Spiral (Multi-Turn) Rings

A Spiral ring is manufactured like a spring, consisting of one or more 360° turns of Teflon material. This design provides significant flexibility.

It is ideal for installations where space is limited or where a standard split ring might be difficult to install. It can be "wound" into a groove, making it suitable for pistons with small diameters.

Contoured Rings

Contoured rings have a concave face designed to match the curved profile of the adjacent O-ring. This shape provides more uniform support and reduces stress concentrations on the O-ring.

These are often used in high-pressure dynamic systems where maximizing the life and performance of the O-ring is a top priority.

Understanding the Trade-offs

Selecting a backup ring involves weighing performance against practicality. No single type is universally superior.

Sealing Integrity vs. Installation Ease

The primary trade-off is between the Solid and cut rings (Split and Spiral). A Solid ring offers a theoretically perfect, gap-free seal but can be difficult or impossible to install in many designs.

A Split or Spiral ring provides a minor potential leak or extrusion path at its cut, but this is negligible in most applications and is a necessary compromise for practical installation.

Material Selection and Fillers

While often called "Teflon," the base PTFE material can be blended with fillers to enhance specific properties.

Virgin PTFE is used for general-purpose applications. Glass-filled PTFE provides enhanced strength and dimensional stability under load. Graphite-filled PTFE offers improved wear resistance and thermal conductivity.

Common Applications by Industry

The versatility of these rings makes them critical in several key sectors.

Hydraulic and Pneumatic Systems

This is the most common use case. In hydraulic cylinders, valves, and pumps, backup rings are essential for handling the high pressures that would otherwise destroy standard O-rings.

Aerospace and Automotive

In these industries, reliability is paramount. Backup rings are used in flight control actuators, landing gear systems, and fuel systems where high performance and resistance to aggressive fluids are required.

Chemical and Food Processing

Teflon's chemical inertness makes these rings perfect for sealing systems that handle aggressive acids, solvents, or bases. In food and beverage applications, the material's purity and resistance to cleaning agents ensure hygienic operation.

Selecting the Right Backup Ring for Your System

Your final choice should be guided by the specific operational requirements of your equipment.

- If your primary focus is maximum sealing performance in a static application: The Solid (uncut) ring is the superior choice as it provides no extrusion or leak path.

- If your primary focus is ease of installation for dynamic reciprocating seals: The Split (scarf-cut) ring offers the best balance of performance and practicality.

- If your primary focus is installation in a tight space or a piston with a small diameter: The Spiral (multi-turn) ring provides the necessary flexibility to be wound into place.

- If your primary focus is enhanced support and extended O-ring life in high-pressure dynamic systems: The Contoured ring's shape provides superior stability and reduces localized stress.

By understanding these core types and their trade-offs, you can confidently specify the precise component needed for system reliability and longevity.

Summary Table:

| Type | Key Feature | Primary Use Case |

|---|---|---|

| Solid (Uncut) | Continuous, gap-free ring | Static seals for maximum support |

| Split (Scarf-Cut) | Single angled cut for easy installation | Dynamic reciprocating applications (e.g., hydraulic cylinders) |

| Spiral (Multi-Turn) | Flexible, spring-like design | Tight spaces or small-diameter pistons |

| Contoured | Concave face matching O-ring profile | High-pressure dynamic systems for extended O-ring life |

Need a custom Teflon backup ring solution for your application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including precision backup rings, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we deliver:

- Custom Fabrication: From prototypes to high-volume orders, tailored to your exact specifications.

- Material Expertise: Virgin, glass-filled, or graphite-filled PTFE to meet your performance needs.

- Uncompromising Precision: Ensuring reliability and longevity in the most demanding environments.

Let us help you prevent O-ring extrusion and enhance your system's reliability. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions