At its core, a Polytetrafluoroethylene (PTFE) liner is a problem-solver. The main benefits are its exceptionally low friction, extreme chemical inertness, high-temperature stability, and durability. These properties make it an indispensable material for preventing corrosion, reducing wear, and ensuring purity in demanding industrial, medical, and consumer applications.

The true value of a PTFE liner lies in its unique combination of elite characteristics. It simultaneously addresses challenges of friction, chemical attack, and temperature extremes that few other materials can withstand.

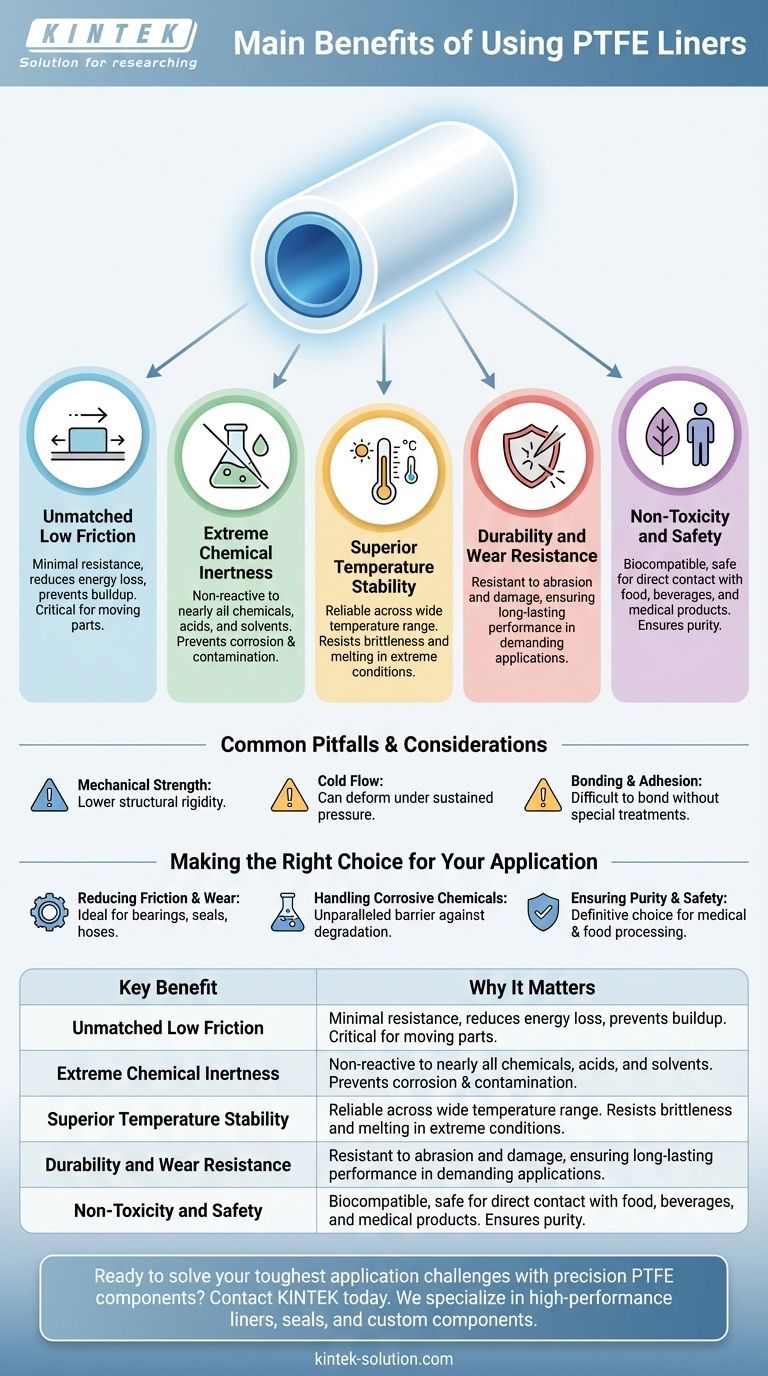

The Core Properties of PTFE Liners

Understanding why PTFE is so effective requires looking at its fundamental properties. Each one solves a specific engineering or operational challenge.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This means surfaces slide against it with minimal resistance.

This non-stick quality is critical for reducing energy loss in piping systems, preventing material buildup, and ensuring smooth operation in moving parts like bearings and seals.

Extreme Chemical Inertness

The strength of the carbon-fluorine bonds in PTFE's molecular structure makes it non-reactive with nearly all chemicals.

It is highly resistant to aggressive acids, bases, and organic solvents. This makes PTFE liners essential for containing and transporting corrosive materials without degradation or contamination.

Superior Temperature Stability

PTFE liners perform reliably across an exceptionally wide range of temperatures.

This thermal stability ensures consistent performance in applications involving extreme heat or cryogenic conditions, preventing the liner from becoming brittle or melting.

Durability and Wear Resistance

Despite its smooth surface, PTFE is a highly durable material resistant to abrasion and damage.

This resilience is vital in applications like medical devices, including catheters and guidewires, where the liner must protect the instrument from wear and tear during repeated use.

Non-Toxicity and Safety

PTFE is inherently non-toxic and biocompatible, making it safe for direct contact with sensitive products.

This property is why it is widely approved and used for applications in the food, beverage, and medical industries, where purity is non-negotiable.

Common Pitfalls and Considerations

While PTFE is a high-performance material, it's crucial to understand its limitations to apply it correctly. Its unique properties create specific engineering trade-offs.

Mechanical Strength

PTFE is not a structural material. While durable against wear and friction, it has lower tensile strength and rigidity compared to metals or other engineering plastics.

Susceptibility to "Cold Flow"

Under sustained pressure, especially at elevated temperatures, PTFE can slowly deform or "creep." This must be accounted for in high-load gasket or seal designs.

Bonding and Adhesion

The same non-stick property that makes PTFE so valuable also makes it very difficult to bond to other substrates. Attaching a PTFE liner often requires special surface treatments like chemical etching to achieve a durable bond.

Making the Right Choice for Your Application

Selecting a PTFE liner is about matching its elite properties to your primary challenge.

- If your primary focus is reducing friction and wear: PTFE is an ideal choice for bearings, seals, and hose systems where you need to minimize energy loss and extend the life of moving components.

- If your primary focus is handling corrosive chemicals: A PTFE liner provides an unparalleled barrier against nearly all acids, bases, and solvents, protecting your equipment from degradation.

- If your primary focus is ensuring purity and safety: The non-toxic and inert nature of PTFE makes it the definitive choice for medical devices and food processing equipment where contamination cannot be risked.

Ultimately, choosing PTFE is an investment in reliability and performance under the most challenging conditions.

Summary Table:

| Key Benefit | Why It Matters |

|---|---|

| Extreme Chemical Inertness | Resists nearly all acids, bases, and solvents, preventing corrosion and contamination. |

| Unmatched Low Friction | Reduces wear and energy loss in moving parts like seals and bearings. |

| Superior Temperature Stability | Performs reliably in extreme heat or cryogenic conditions. |

| Non-Toxic & Biocompatible | Ensures purity and safety for medical, food, and beverage applications. |

| Durability & Wear Resistance | Provides long-lasting performance and protection in demanding environments. |

Ready to solve your toughest application challenges with precision PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE liners, seals, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the exact solution for superior chemical resistance, thermal stability, and purity.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific needs and let our experts help you enhance reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs