In load-bearing applications, PTFE is utilized as a self-lubricating solid. Its primary function is to create an extremely low-friction surface between moving parts, eliminating the need for traditional liquid lubricants like oil or grease. Components such as bearings, piston rings, and slide plates are made from PTFE to directly reduce wear, minimize energy loss, and ensure smooth, consistent movement under load.

The core value of PTFE in load-bearing systems is its ability to function as a dry lubricant. This eliminates the need for external oils or greases, drastically reducing maintenance while preventing component wear and ensuring smooth, efficient operation in environments where traditional lubrication would fail or cause contamination.

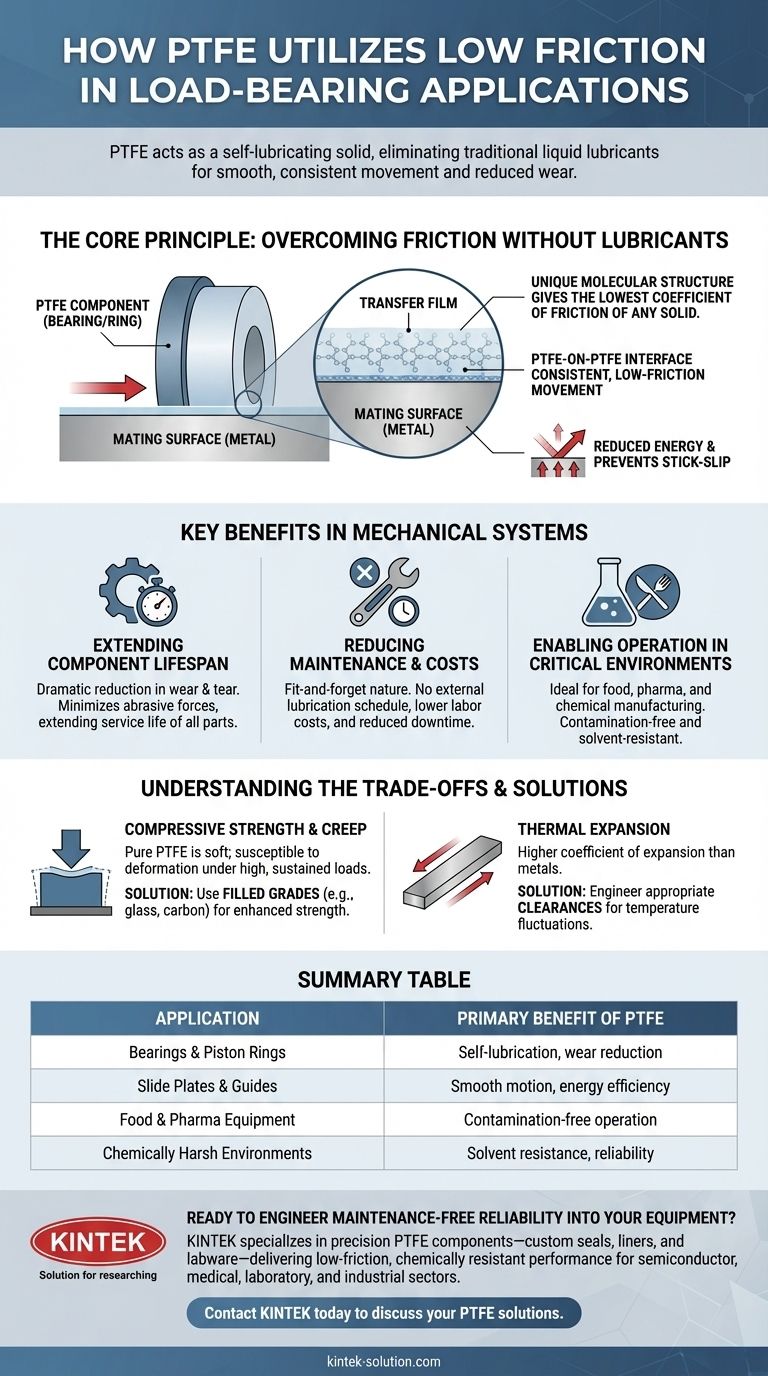

The Core Principle: Overcoming Friction Without Lubricants

PTFE's effectiveness comes from its unique molecular structure, which gives it the lowest coefficient of friction of any known solid. This property is not a coating or an additive; it is an inherent characteristic of the material itself.

The Mechanism of Self-Lubrication

When a component made of PTFE slides against another surface, it creates a transfer film. This means a microscopic layer of PTFE is deposited on the mating surface, resulting in a smooth, PTFE-on-PTFE interface.

This mechanism is what provides the consistent, low-friction movement, as the parts are essentially gliding on a thin layer of the polymer itself.

Direct Impact on Performance

This self-lubricating action reduces the energy required to move a system, improving overall operational efficiency. It prevents the "stick-slip" phenomenon common in other materials, leading to smoother and more predictable motion, which is critical in precision machinery.

Key Benefits in Mechanical Systems

Deploying PTFE in load-bearing roles is a strategic choice to solve specific engineering challenges, moving beyond simple friction reduction to deliver tangible operational advantages.

Extending Component Lifespan

The most direct benefit of low friction is a dramatic reduction in wear and tear. By minimizing the abrasive forces between moving parts, PTFE extends the service life of both the PTFE component and the surface it slides against.

This is especially valuable for gears, guides, and other parts where constant sliding action would otherwise lead to rapid degradation.

Reducing Maintenance and Costs

PTFE components require no external lubrication schedule. This "fit-and-forget" nature eliminates the labor and material costs associated with regular greasing or oiling, while also reducing equipment downtime for maintenance.

Enabling Operation in Critical Environments

Many industries cannot use traditional lubricants due to the risk of contamination or chemical incompatibility. PTFE is an ideal solution in these scenarios.

It is widely used in food processing, pharmaceutical, and textile manufacturing, where product purity is paramount. It also excels in applications where solvents would dissolve and wash away conventional lubricants.

Understanding the Trade-offs

While its low-friction properties are unparalleled, PTFE is not a universal solution. An objective assessment requires acknowledging its mechanical limitations.

Compressive Strength and Creep

Compared to metals, pure PTFE is a relatively soft material. Under high, sustained loads, it can be susceptible to creep, which is the tendency to slowly deform over time.

For applications with very high contact pressures, filled grades of PTFE (mixed with glass, carbon, or other agents) are often used to enhance strength and rigidity.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. This means it expands and contracts more significantly with temperature changes.

Designers must account for this by engineering appropriate clearances to prevent binding or failure in systems that experience wide temperature fluctuations.

When to Specify PTFE for Your Application

Choosing PTFE is about matching its unique strengths to your primary operational goal.

- If your primary focus is reducing maintenance and extending service life: PTFE is ideal for creating components that require no external lubrication schedule, directly engineering reliability into the system.

- If you are designing for a clean or chemically harsh environment: Use PTFE where traditional oils or greases would contaminate products (e.g., food, pharma) or be dissolved by solvents.

- If your goal is to maximize energy efficiency and smooth operation: PTFE minimizes frictional losses in sliding systems, ensuring more input energy is converted into useful work with predictable, consistent movement.

Ultimately, incorporating PTFE is a strategic decision to replace ongoing maintenance with inherent material performance.

Summary Table:

| Application | Primary Benefit of PTFE |

|---|---|

| Bearings & Piston Rings | Self-lubrication, wear reduction |

| Slide Plates & Guides | Smooth motion, energy efficiency |

| Food & Pharma Equipment | Contamination-free operation |

| Chemically Harsh Environments | Solvent resistance, reliability |

Ready to engineer maintenance-free reliability into your equipment?

KINTEK specializes in precision PTFE components—from custom seals and liners to complex labware—that deliver the low-friction, chemically resistant performance detailed in this article. Whether you need prototypes or high-volume production for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures your components meet exacting standards for durability and efficiency.

Contact KINTEK today to discuss how our PTFE solutions can solve your specific load-bearing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the advantages of spring-loaded lift check valves? Achieve Reliable, Non-Slam Backflow Prevention

- What is Teflon Lined Carbon Steel Pipe, and what are its properties? A Cost-Effective Solution for Corrosive Fluids

- What are the common types of fillers used in PTFE compounds? Enhance Performance for Demanding Applications

- What industries are PTFE gaskets particularly suitable for? Ideal for Chemical, Pharma, and Food Processing

- What industries commonly use PTFE extruded rods? Key Applications in High-Performance Sectors

- What are the operating temperature ranges for PTFE and nylon? Choose the Right Polymer for Extreme or Moderate Heat

- How do PTFE seals contribute to reducing maintenance costs? Slash Costs with Superior Durability

- What is the heat-set process for PTFE seal elements? Simplify Installation and Ensure a Reliable Seal