The most common fillers for PTFE compounds are glass fiber, carbon, graphite, molybdenum disulfide (MoS2), and bronze powder. Other specialized fillers include stainless steel, ceramics, and various polymers like polyimide, which are selected to engineer very specific material properties for demanding applications.

Fillers are added to Polytetrafluoroethylene (PTFE) to fundamentally enhance its mechanical properties. While virgin PTFE offers exceptional chemical resistance and low friction, it is inherently soft and prone to deformation (creep) under load; fillers are the primary method for improving its wear resistance, strength, and thermal conductivity.

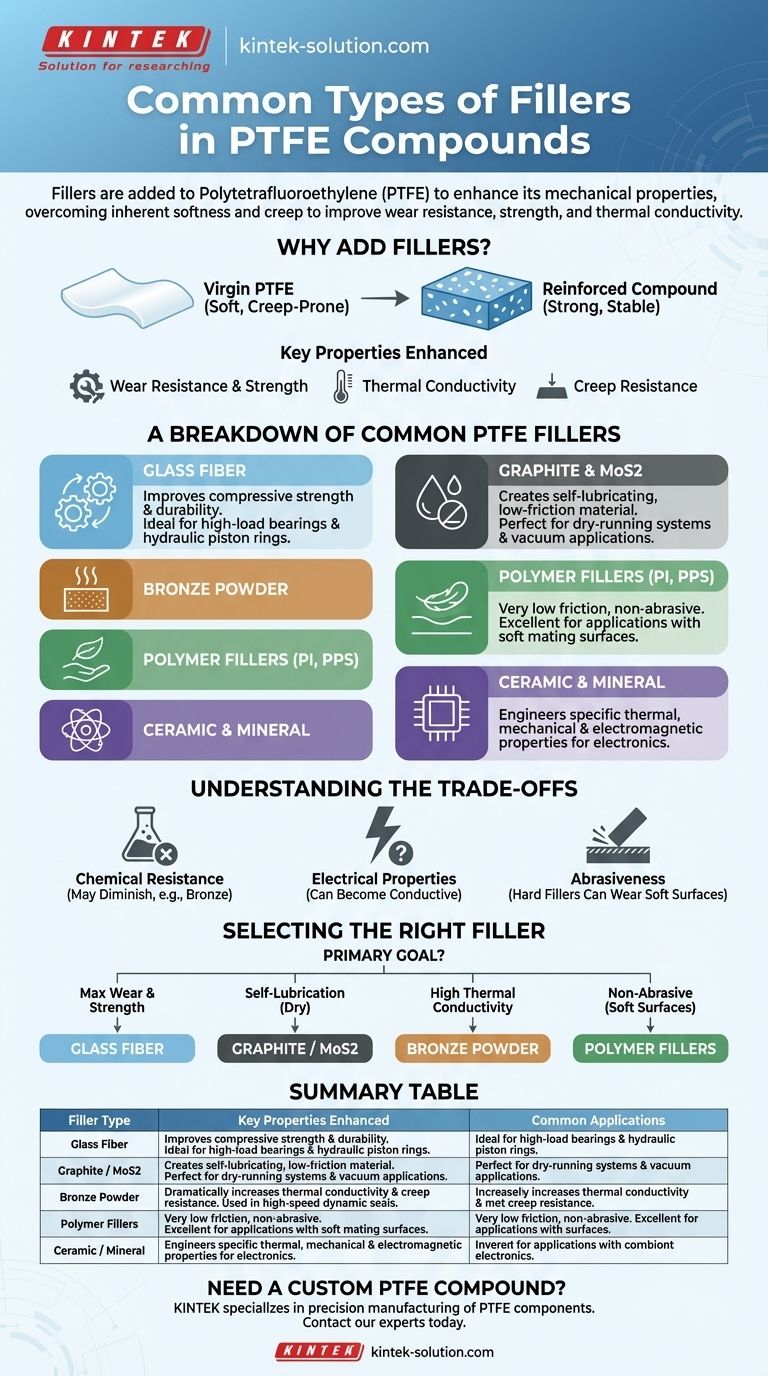

Why Add Fillers to PTFE?

While virgin PTFE has remarkable characteristics, it falls short in applications requiring mechanical integrity. Fillers are the solution to these inherent limitations.

Overcoming PTFE's Core Weaknesses

Virgin PTFE is soft and exhibits high flexibility. This leads to creep, or deformation under sustained pressure, and poor wear resistance when subjected to friction.

Adding a filler creates a composite material. This new material structure significantly improves compressive strength and rigidity, allowing PTFE to be used in demanding physical applications.

Key Properties Enhanced by Fillers

The primary goal of using fillers is to augment specific performance characteristics. These enhancements include drastically improved wear resistance, reduced creep, and increased thermal conductivity to dissipate heat more effectively.

Some fillers can also be used to modify electrical properties, transforming PTFE from a pure insulator into a static-dissipative or conductive material.

A Breakdown of Common PTFE Fillers

The choice of filler directly dictates the final properties of the compound. Each material offers a unique profile of benefits tailored to different operational environments.

Glass Fiber

Glass is the most widely used filler in PTFE. It provides a significant boost to compressive strength and overall durability.

This makes glass-filled PTFE a common choice for applications like hydraulic piston rings where high wear resistance under pressure is critical.

Graphite and Molybdenum Disulfide (MoS2)

These two fillers are often used to enhance PTFE's already low coefficient of friction, creating a self-lubricating material.

Graphite improves wear properties and is electrically conductive, while MoS2 offers excellent performance in vacuum or dry-running applications. They are frequently combined to maximize these benefits.

Bronze Powder

Bronze is added to dramatically increase thermal conductivity and improve resistance to creep. Materials with bronze fillers can dissipate heat far more effectively than other compounds.

This makes bronze-filled PTFE ideal for high-speed dynamic applications where friction-generated heat can be a point of failure.

Polymer Fillers (Polyimide, PPS)

High-performance polymers like Polyimide (PI) or Polyphenylene Sulfide (PPS) can be used as fillers. These create a compound with a very low friction coefficient that is non-abrasive.

Because they are less abrasive than glass, polymer fillers are an excellent choice for applications involving softer mating surfaces like stainless steel, aluminum, or other plastics.

Ceramic and Mineral Fillers

Fillers like alumina (Al2O3) or calcium fluoride (CaF2) are used to engineer specific thermal, mechanical, and electromagnetic properties.

They are often specified for high-tech applications in electronics or advanced machinery where precise material characteristics are non-negotiable.

Understanding the Trade-offs

Adding fillers is not without compromises. Enhancing one property often means altering another, which is a critical consideration during material selection.

Impact on Chemical Resistance

While PTFE is famous for its near-universal chemical inertness, some fillers can diminish this property. Bronze-filled PTFE, for example, has significantly lower resistance to acids and alkalis.

Effect on Electrical Properties

Virgin PTFE is an excellent electrical insulator. The addition of conductive fillers like carbon, graphite, or stainless steel will alter this, making the material more conductive and unsuitable for applications requiring high dielectric strength.

Abrasiveness

Hard fillers like glass fiber can be abrasive to the surfaces they run against, especially softer metals. In such cases, a less abrasive filler like graphite or a polymer would be a more suitable choice to prevent premature wear on mating components.

Selecting the Right Filler for Your Application

The optimal PTFE compound is determined entirely by its intended use. Understanding your primary performance goal is the key to making the correct choice.

- If your primary focus is maximum wear resistance and compressive strength: Glass fiber is the most common and cost-effective choice.

- If your primary focus is self-lubrication and low friction, especially in dry-running systems: Graphite, Molybdenum Disulfide (MoS2), or a combination of the two is ideal.

- If your primary focus is high thermal conductivity and creep resistance: Bronze filler provides the best performance for dissipating heat in dynamic systems.

- If your primary focus is running against soft metal surfaces without causing abrasion: Polymer fillers like polyimide offer excellent lubricity without damaging the mating component.

Choosing the correct filler transforms PTFE from a specialized polymer into a versatile and robust engineering material capable of solving a wide range of mechanical challenges.

Summary Table:

| Filler Type | Key Properties Enhanced | Common Applications |

|---|---|---|

| Glass Fiber | Wear resistance, compressive strength | Hydraulic piston rings, high-load bearings |

| Graphite / MoS2 | Self-lubrication, low friction | Dry-running systems, vacuum applications |

| Bronze Powder | Thermal conductivity, creep resistance | High-speed dynamic seals, bushings |

| Polymer Fillers (PI, PPS) | Low friction, non-abrasive | Applications with soft mating surfaces |

| Ceramic / Mineral | Specific thermal/electrical properties | Electronics, advanced machinery |

Need a custom PTFE compound for your specific application?

The right filler is critical to performance. KINTEK specializes in the precision manufacturing of PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. We leverage our expertise to help you select or custom-formulate the ideal PTFE compound to solve your unique challenges—improving wear, reducing friction, managing heat, or preventing creep.

We offer full custom fabrication, from rapid prototypes to high-volume production runs, ensuring you get a component engineered for success.

Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the available grades of PTFE balls? Choose the Right Grade for Your Application

- What temperature range can Teflon (PTFE) balls withstand? -200°C to +260°C Performance Guide

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime