The exceptional temperature range of PTFE gaskets is a cornerstone of their value in industrial settings. This property allows them to maintain sealing integrity in conditions ranging from cryogenic lows to high-temperature processing, ensuring operational reliability where other materials would fail. This versatility directly translates to a longer service life, reduced downtime, and improved safety across a vast array of demanding applications.

The true benefit of PTFE's wide temperature range is not just its performance at extremes, but its stability across them. This predictable performance, combined with its chemical inertness, makes it a uniquely reliable and cost-effective solution for sealing in harsh and fluctuating industrial environments.

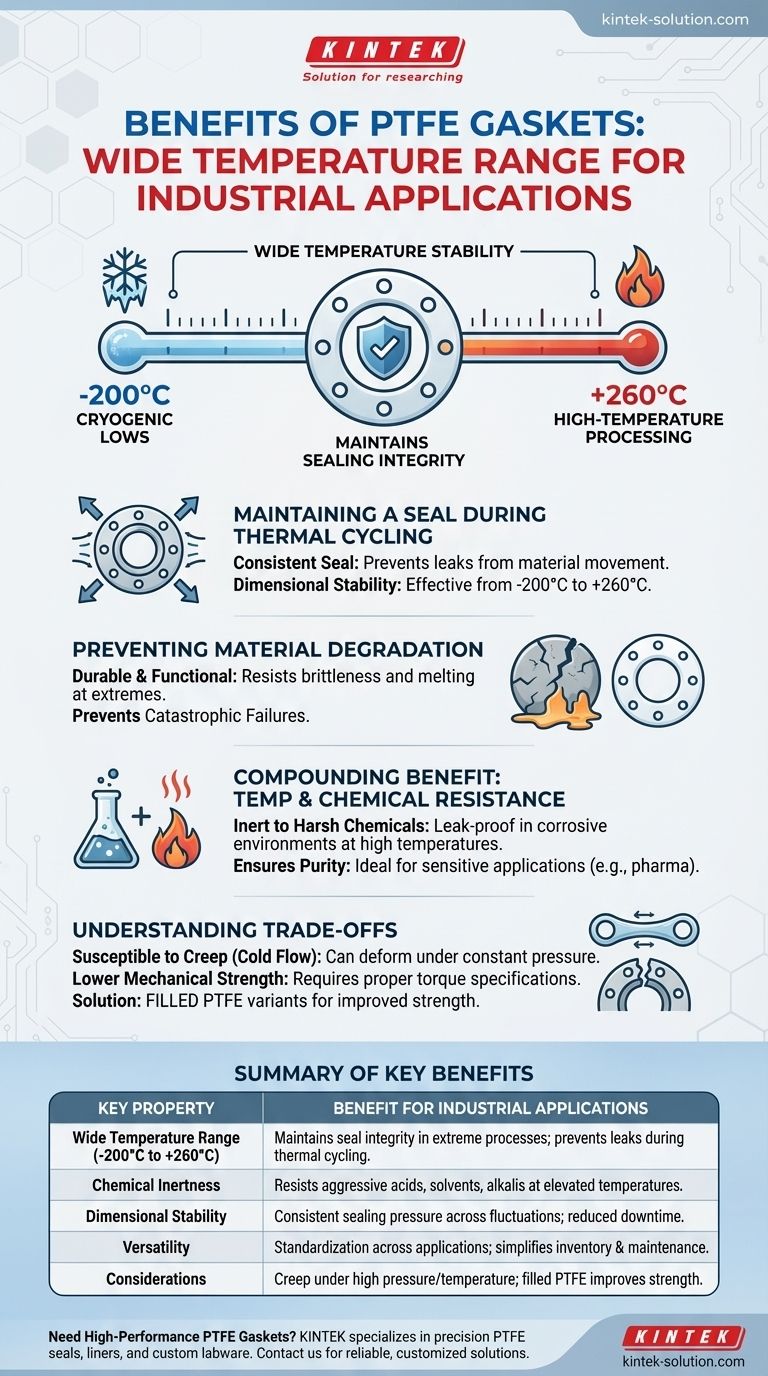

Why Temperature Stability is Critical for Sealing

A gasket's primary function is to create a reliable seal between two surfaces, preventing leaks. Temperature fluctuations are a primary enemy of this function, but PTFE's inherent properties provide a robust defense.

Maintaining a Seal During Thermal Cycling

Most materials expand when heated and contract when cooled. For a gasket, this movement can compromise the sealing pressure, leading to leaks.

PTFE, however, exhibits remarkable dimensional stability across its entire operating range. It maintains a consistent, effective seal whether it's in a cryogenic process or a high-temperature steam line.

Preventing Material Degradation at Extremes

Extreme temperatures can physically and chemically destroy many sealing materials. High heat can cause elastomers to become brittle or melt, while extreme cold can make them lose flexibility and crack.

PTFE remains durable and functional from approximately -200°C to +260°C (-328°F to +500°F). This prevents the material degradation that causes catastrophic seal failure in less resilient materials.

Enabling Versatility Across Processes

This wide temperature band allows engineers to standardize on a single gasket material for many different applications within a facility.

Using PTFE for both high-temperature reactors and low-temperature fluid transport simplifies inventory, reduces the risk of incorrect material selection, and streamlines maintenance procedures.

The Compounding Benefit: Temperature and Chemical Resistance

While its temperature range is a key feature, its true power is unlocked when combined with PTFE's legendary chemical inertness. Many industrial processes are not just hot or cold; they are also corrosive.

Sealing in Harsh Chemical Environments

Industries like petrochemical and chemical manufacturing often involve aggressive acids, solvents, or alkalis at elevated temperatures.

PTFE is virtually inert to all industrial chemicals. It will not swell, degrade, or dissolve, ensuring a leak-proof seal even when handling the most corrosive substances at high temperatures.

Ensuring Purity in Sensitive Applications

In pharmaceutical or medical device manufacturing, gaskets cannot leach contaminants into the product, especially during heat sterilization cycles.

Because PTFE is stable at sterilization temperatures and does not react with process media, it ensures product purity and compliance with strict industry standards.

Understanding the Trade-offs of PTFE

No material is perfect. While its temperature and chemical resistance are top-tier, it's critical to understand PTFE's limitations to ensure proper application.

Susceptibility to Creep (Cold Flow)

PTFE's most well-known weakness is creep, or cold flow. This is the tendency for the material to slowly deform over time when under constant pressure, which can lead to a loss of sealing force.

This effect is more pronounced at higher temperatures. In high-pressure, high-temperature flange applications, this must be accounted for during design and maintenance.

Lower Mechanical Strength

Compared to metallic gaskets or even some advanced polymers, pure PTFE is a relatively soft material.

This makes it susceptible to damage from over-tightening during installation, which can extrude the gasket out of the flange and cause a premature failure. Proper torque specifications are essential.

The Role of Fillers

To counteract these limitations, PTFE is often blended with fillers like glass, carbon, or bronze. These "filled PTFE" variants offer significantly improved creep resistance and mechanical strength.

However, adding fillers can sometimes slightly reduce the gasket's chemical resistance or temperature ceiling, creating a trade-off that must be evaluated for the specific application.

Making the Right Choice for Your Application

Selecting the correct gasket requires balancing the demands of your process with the specific properties of the material.

- If your primary focus is broad chemical exposure across extreme temperature cycles: Pure, virgin PTFE is an excellent choice for its unmatched stability and inertness.

- If your application involves high pressure combined with high temperatures: A filled PTFE gasket (e.g., glass-filled) is likely necessary to resist creep and maintain a long-term seal.

- If your goal is to reduce long-term maintenance costs: Standardizing on PTFE gaskets where appropriate can be highly effective, but ensure your technicians are trained on proper installation torque to prevent damage to the softer material.

By understanding both the unique advantages and the practical limitations of PTFE, you can leverage its wide temperature range to engineer more resilient and efficient systems.

Summary Table:

| Key Property | Benefit for Industrial Applications |

|---|---|

| Wide Temperature Range (-200°C to +260°C) | Maintains seal integrity in cryogenic and high-heat processes, preventing leaks during thermal cycling. |

| Chemical Inertness | Resists aggressive acids, solvents, and alkalis, even at elevated temperatures. |

| Dimensional Stability | Provides consistent sealing pressure across temperature fluctuations, reducing downtime. |

| Versatility | Allows standardization across multiple applications, simplifying inventory and maintenance. |

| Considerations | Susceptible to creep under high pressure/temperature; filled PTFE variants improve strength. |

Need a PTFE gasket that withstands extreme temperatures and corrosive environments?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures reliable sealing solutions tailored to your specific temperature and chemical requirements, from prototypes to high-volume orders.

Contact us today to discuss how our PTFE gaskets can enhance your operational reliability and safety. Get in touch with our experts for a customized solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key industries that rely on PTFE rotary shaft seals? Critical Sealing for Extreme Environments

- What are the temperature limits for PTFE packing performance? Withstand -200°C to 260°C for Reliable Sealing

- What is a Teflon lip seal and what material is it made from? The Ultimate Guide to High-Performance PTFE Seals

- What types of PTFE processing machines are commonly used? From Extrusion to Precision Machining

- Why is PTFE considered a safe choice for O-ring seals? Ensure Reliability in Extreme Conditions

- How does PTFE compare to other elastomers in temperature resilience? Unmatched Performance from -200°C to 260°C

- What are the future trends for PTFE sheets in industrial innovation? From Commodity to Custom-Engineered Solutions

- Are PTFE butterfly valves suitable for high-pressure applications? Balancing Chemical Resistance & Pressure Limits