The most common PTFE processing machines are extruders, specifically rod and tube pushers, and compression molding machines. These devices are designed to handle the unique properties of raw PTFE material, forming it into standardized stock shapes that can then be further refined.

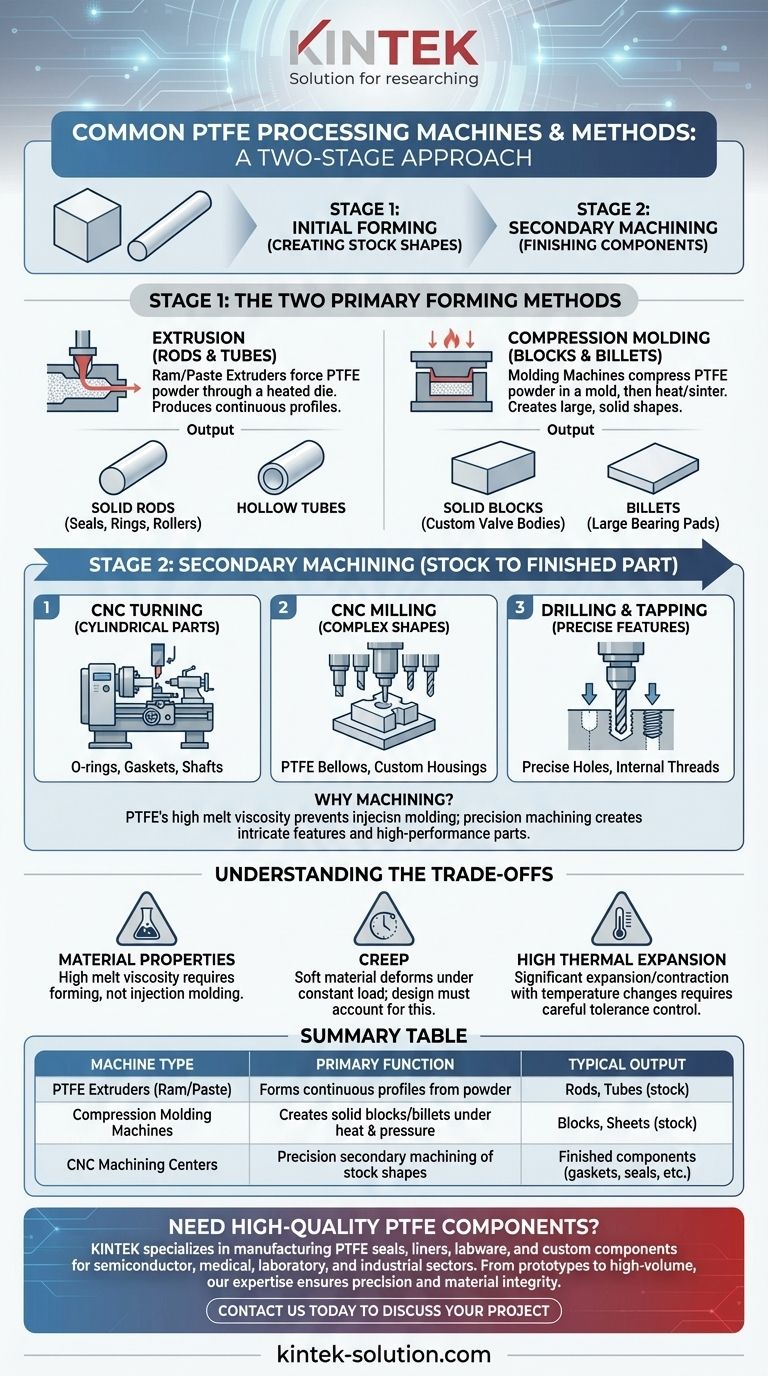

The core principle of PTFE processing is often a two-stage approach: first, using extruders or molding machines to create a solid, stable "stock" shape like a rod or block, and second, using precision CNC machines to craft the final, intricate component from that stock material.

The Two Primary Forming Methods

To understand PTFE processing, it's essential to differentiate between the initial forming of the material and the final machining of the part. The initial forming is handled by specialized machines that create bulk shapes.

Extrusion (Creating Rods and Tubes)

PTFE extruders, often called ram or paste extruders, are used to create continuous, uniform profiles. This process involves forcing powdered PTFE resin through a heated die to form a specific shape.

The two primary types are rod extruders (for solid cylinders) and tube extruders (for hollow cylinders). These machines produce the raw material used for creating parts like seals, rings, and rollers.

Compression Molding (Creating Blocks and Billets)

Molding machines are used to create large, solid blocks or "billets" of PTFE. In this process, PTFE powder is placed into a mold, compressed under immense pressure, and then heated in a process called sintering.

This method is ideal for producing large, thick sheets or blocks that will later be machined into complex, non-cylindrical components, such as a large bearing pad or a custom-designed valve body.

From Stock Shape to Finished Part: Secondary Machining

The parts produced by extrusion and molding are rarely the final product. They are considered "stock material" that requires high-precision secondary machining to achieve the final desired geometry and tolerances.

Why Secondary Machining is Necessary

PTFE's unique properties prevent it from being injection molded like many common plastics. The initial forming processes provide a stable, solid piece of material, but only precision machining can create the intricate features required for high-performance applications.

Common Machining Techniques

Once a rod, tube, or block is formed, it is typically shaped using computer-controlled equipment.

- CNC Turning: This is used for creating cylindrical parts like O-rings, gaskets, and shafts. The PTFE stock material is spun while a cutting tool shapes it.

- CNC Milling: This is used for more complex shapes with intricate patterns, slots, or cavities. It's the method used to create components like PTFE bellows or custom housings.

- Drilling and Tapping: These processes are used to create precise holes and internal threads within a PTFE component.

Understanding the Trade-offs

While highly effective, the multi-stage process for creating PTFE parts has specific considerations that are crucial for engineers and designers to understand.

Material Properties Dictate the Process

PTFE has an extremely high melt viscosity, meaning it doesn't flow like a liquid when heated. This property makes it unsuitable for common, high-speed methods like injection molding. The reliance on extrusion and compression molding is a direct result of this material constraint.

The Challenge of "Creep"

PTFE is a relatively soft material that can slowly deform over time if placed under a constant load, a phenomenon known as creep. Part design and machining processes must account for this to ensure long-term dimensional stability, especially in high-pressure sealing applications.

High Thermal Expansion

PTFE expands and contracts with temperature changes more than most metals. This requires careful control of tolerances during machining to ensure the final part will fit and function correctly across its intended operating temperature range.

Making the Right Choice for Your Goal

The right processing path depends entirely on the geometry and requirements of the final component you need to produce.

- If your primary focus is long, continuous parts like rods or tubing: The process begins with extrusion to create the initial stock shape.

- If your primary focus is large blocks or custom-shaped billets: The process must start with compression molding to form the bulk material.

- If your primary focus is high-precision finished components like gaskets or seals: The final, critical step is always CNC machining from a pre-formed stock shape.

Ultimately, selecting the correct combination of forming and machining ensures your PTFE components meet the precise demands of their application.

Summary Table:

| Machine Type | Primary Function | Typical Output |

|---|---|---|

| PTFE Extruders (Ram/Paste) | Forms continuous profiles from powder | Rods, Tubes (stock for seals, rings) |

| Compression Molding Machines | Creates solid blocks/billets under heat and pressure | Blocks, Sheets (stock for complex parts) |

| CNC Machining Centers | Precision secondary machining of stock shapes | Finished components (gaskets, seals, custom parts) |

Need high-quality, precision-machined PTFE components?

At KINTEK, we specialize in manufacturing PTFE seals, liners, labware, and other custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise spans the entire process—from selecting the right forming method to final precision CNC machining—ensuring your parts meet exact specifications and perform reliably.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and material integrity to overcome challenges like PTFE creep and thermal expansion.

Contact us today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments