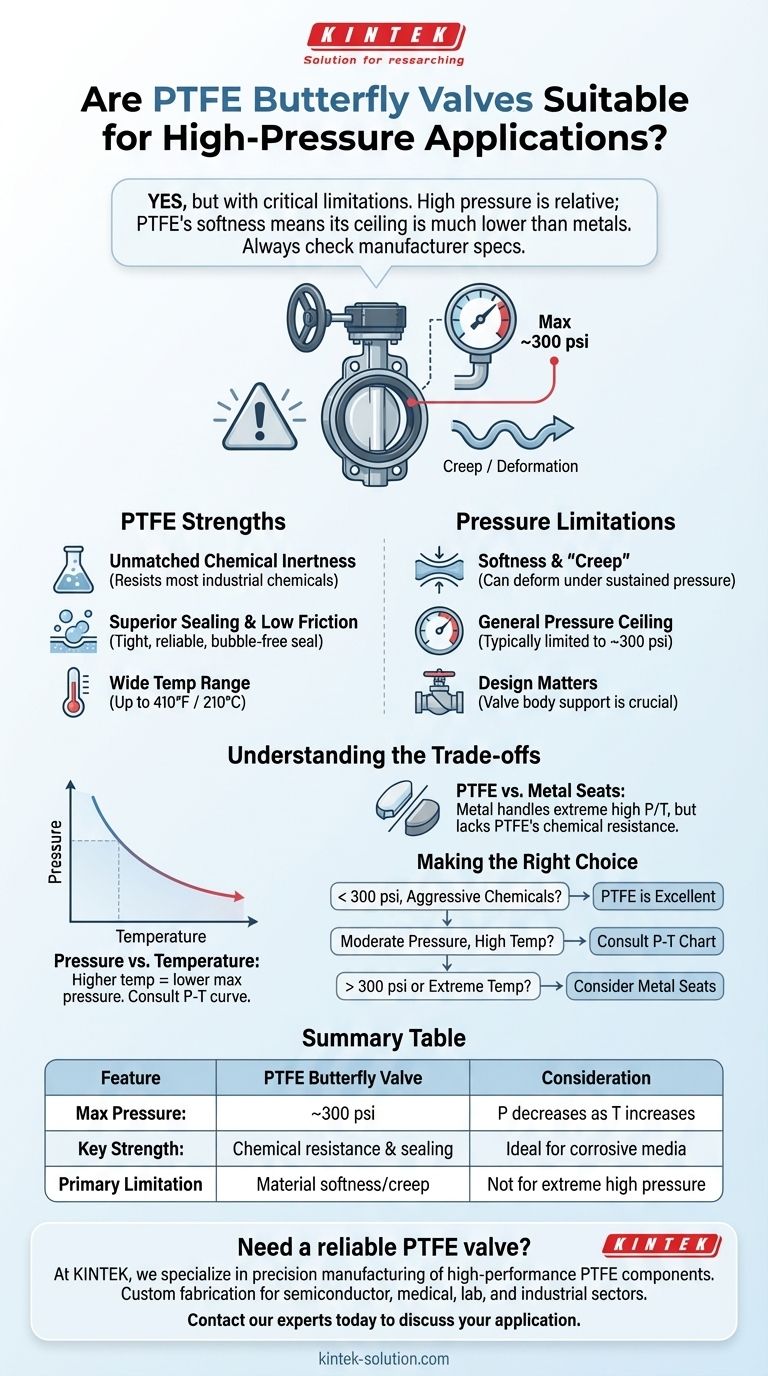

Yes, PTFE butterfly valves are suitable for many high-pressure applications, but this suitability comes with critical limitations. The term "high pressure" is relative, and for a soft material like PTFE, the ceiling is much lower than for metals. The valve's specific design and construction are the ultimate factors determining its maximum allowable pressure rating.

The core takeaway is this: PTFE offers unmatched chemical resistance and excellent sealing, making it ideal for corrosive environments, but its inherent softness means it can deform under pressure. For this reason, its use is generally limited to applications below 300 psi, and you must always defer to the manufacturer's official specifications.

The Strengths of PTFE in Valve Design

Before examining its limitations, it's important to understand why PTFE is such a sought-after material for valve components in the first place.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and corrosive media. This makes it an essential choice for applications in chemical processing, oil and gas, and pharmaceuticals where other materials would quickly degrade.

Superior Sealing and Low Friction

The material's low coefficient of friction allows the valve disc to rotate smoothly against the seat with minimal torque. This reduces wear, extends the valve's service life, and ensures a tight, reliable bubble-free seal.

Wide Operating Temperature Range

PTFE seats can handle a broad range of temperatures, typically up to around 410°F (210°C). This thermal stability makes them versatile for processes that involve significant temperature fluctuations.

Understanding PTFE's Pressure Limitations

The very properties that make PTFE an excellent sealant also create its primary limitation: its softness. This is the central factor in its pressure-handling capability.

The Concept of "Creep" and Deformation

Under sustained mechanical stress, soft materials like PTFE can slowly deform or "creep." High pressure exerts this stress on the valve seat. If the pressure is too great, the PTFE can be extruded out of position, leading to seal failure.

The General Pressure Ceiling

While dependent on the specific valve design, a general upper limit for many PTFE-seated butterfly valves is around 300 psi. Applications requiring pressure significantly above this threshold are often considered outside the ideal operating window for standard PTFE designs.

The Critical Role of Valve Design

Manufacturers use specific engineering techniques to mitigate creep. The valve body can be designed to fully support and contain the PTFE seat, which increases its ability to withstand pressure. This is why a valve from one manufacturer may have a different pressure rating than another, even if both use PTFE seats.

Understanding the Trade-offs

Selecting a valve is always an exercise in balancing competing requirements. With PTFE, the primary trade-off is between chemical compatibility and mechanical strength.

Pressure vs. Temperature

A valve's pressure rating is not a static number. As the operating temperature increases, the PTFE material softens further, which reduces its maximum allowable pressure. Always consult the manufacturer's pressure/temperature curve to ensure safe operation.

PTFE vs. Metal Seats

For true high-pressure and high-temperature service, metal-seated butterfly valves are often the preferred choice. Metal seats can handle extreme pressures and temperatures far beyond PTFE's limits. However, they typically lack the broad chemical resistance and bubble-tight sealing capabilities of a soft-seated PTFE valve.

Never Exceed Manufacturer Specifications

The most critical takeaway is that the manufacturer's data sheet is the definitive source of truth. Relying on general guidelines is insufficient; the valve's specific design, engineering, and testing determine its safe operating limits.

Making the Right Choice for Your Application

To select the correct valve, you must first define your system's primary demand.

- If your primary focus is handling aggressive chemicals below 300 psi: A PTFE-lined or seated butterfly valve is likely an excellent and cost-effective choice.

- If your application involves both moderate pressure and high temperatures: You must carefully consult the manufacturer's pressure-temperature chart to verify the valve is rated for those specific conditions.

- If your application involves true high pressure (well above 300 psi) or extreme temperatures: You should investigate high-performance butterfly valves with metal seats or consider other valve types designed for severe service.

Understanding this balance between chemical resistance and mechanical strength is the key to selecting the right valve for your system's safety and longevity.

Summary Table:

| Feature | PTFE Butterfly Valve | Consideration |

|---|---|---|

| Max Pressure | Typically up to 300 psi | Pressure rating decreases as temperature increases |

| Key Strength | Unmatched chemical resistance & excellent sealing | Ideal for corrosive media |

| Primary Limitation | Material softness can lead to creep/deformation | Not for extreme high-pressure service |

| Best For | Chemical processing, pharmaceuticals, labs (moderate pressure) | When chemical inertness is the top priority |

Need a reliable PTFE valve for your specific pressure and chemical requirements?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including seals, liners, and custom labware. Our expertise is crucial for applications in the semiconductor, medical, laboratory, and industrial sectors, where material integrity under pressure is non-negotiable.

We provide custom fabrication from prototypes to high-volume orders, ensuring your valve solution is perfectly engineered for your operating conditions—balancing chemical resistance with mechanical performance.

Contact our experts today to discuss your application and get a valve that delivers both safety and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry