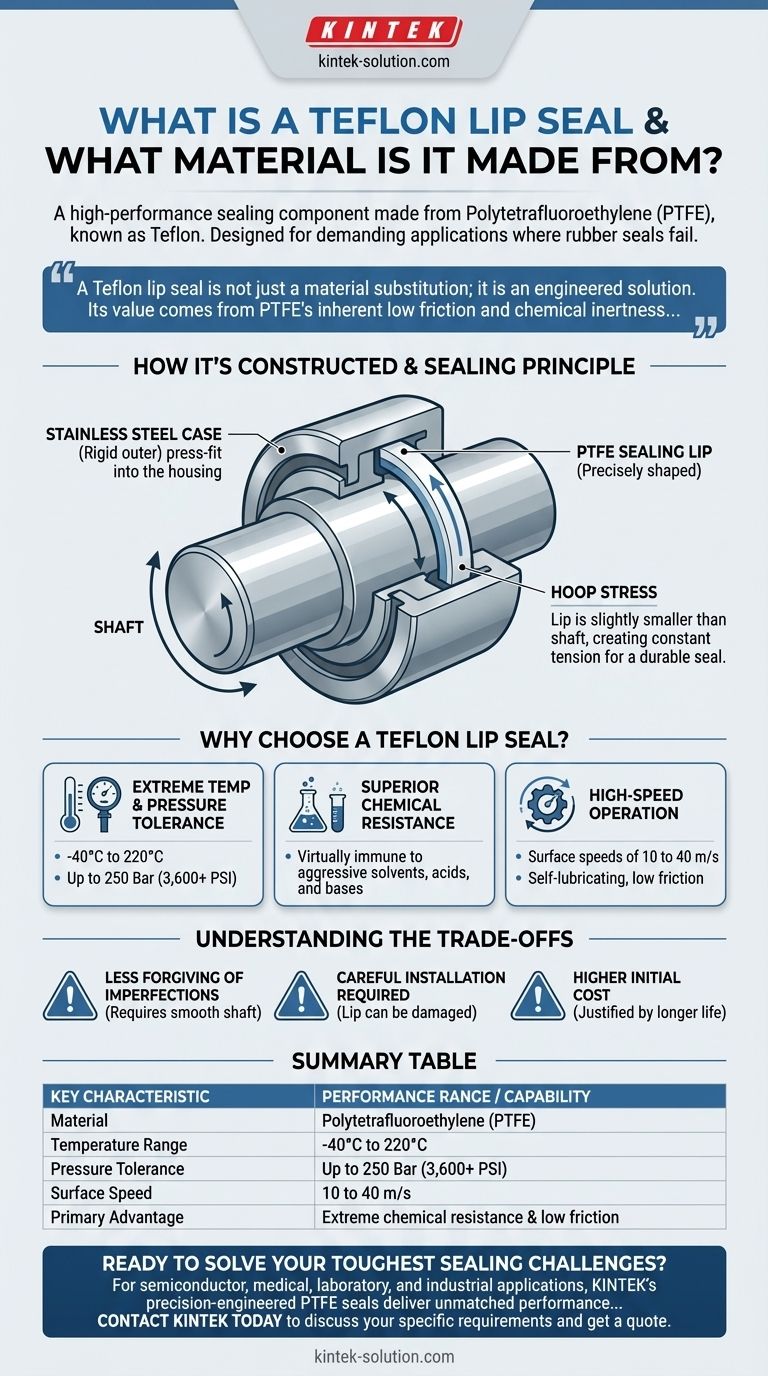

In short, a Teflon lip seal is a high-performance sealing component designed for demanding applications where traditional rubber seals fail. It is made from a fluoropolymer called Polytetrafluoroethylene (PTFE), the material universally known by its brand name, Teflon. Its unique properties allow it to function effectively in environments with high speeds, extreme temperatures, and aggressive chemicals.

A Teflon lip seal is not just a material substitution; it is an engineered solution. Its value comes from PTFE's inherent low friction and chemical inertness, making it the superior choice for high-pressure, high-speed rotating shafts in challenging operational conditions.

What Defines a Teflon Lip Seal?

To understand why these seals are specified for critical applications, we need to look at both their core material and their mechanical construction.

The Core Material: PTFE

The heart of the seal is Polytetrafluoroethylene (PTFE). This is a synthetic fluoropolymer composed of carbon and fluorine atoms.

This chemical structure gives PTFE its signature characteristics: an extremely low coefficient of friction (making it self-lubricating) and exceptional resistance to chemical attack.

How It's Constructed

A Teflon lip seal is often a multi-part assembly, not just a simple ring of PTFE. A typical design includes a rigid outer case, usually made of stainless steel, that is press-fit into the equipment housing.

This case holds the precisely shaped PTFE sealing element (the "lip"). The design ensures the lip is energized against the rotating shaft, creating a reliable seal.

The Sealing Principle: Hoop Stress

Unlike a flexible rubber seal that simply squeezes into place, a Teflon lip seal leverages hoop stress. The sealing lip is manufactured with a diameter slightly smaller than the shaft it will seal against.

When installed, the lip is stretched over the shaft, creating a constant, uniform pressure. This tension, combined with the low-friction nature of PTFE, results in a durable seal that generates minimal heat and wear.

Why Choose a Teflon Lip Seal Over Alternatives?

Engineers specify Teflon lip seals when operational demands exceed the capabilities of standard elastomeric (rubber) seals. The advantages are clear and significant.

Extreme Temperature and Pressure Tolerance

Teflon seals maintain their integrity and performance across a vast temperature range, typically from -40°C to 220°C.

They are also engineered for high-pressure applications, capable of handling pressures up to 250 Bar (over 3,600 PSI), where a rubber seal would be extruded and destroyed.

Superior Chemical Resistance

PTFE is one of the most chemically inert materials used in industry. It is virtually immune to attack from aggressive solvents, acids, and bases, making it essential for chemical processing and pharmaceutical applications.

High-Speed Operation

The self-lubricating, low-friction surface of PTFE is ideal for sealing high-speed rotating shafts. These seals can operate effectively at surface speeds of 10 to 40 m/s, minimizing heat generation and wear that would quickly degrade other materials.

Understanding the Trade-offs

While highly effective, Teflon lip seals are a specialized component, and it's crucial to understand their limitations to avoid misapplication.

Less Forgiving of Imperfections

PTFE is a relatively rigid material compared to elastomers. This means Teflon lip seals are less forgiving of shaft imperfections, surface scratches, or significant misalignment, which can create leak paths.

Careful Installation is Required

The same rigidity that provides stability also means installation requires more care. The seal lip can be damaged if it's forced over sharp edges or installed improperly, compromising its performance from the start.

Higher Initial Cost

As a high-performance, often composite component, the initial procurement cost of a Teflon lip seal is typically higher than that of a standard nitrile or viton rubber seal. This cost, however, is often justified by longer service life and reduced maintenance in demanding environments.

Making the Right Choice for Your Application

Selecting the correct seal depends entirely on the specific demands of your equipment.

- If your primary focus is sealing high-speed rotating equipment: The low-friction properties of a Teflon lip seal are ideal, minimizing heat generation and wear.

- If your primary focus is compatibility with aggressive chemicals or solvents: The inert nature of PTFE makes this seal one of the most reliable choices available.

- If your primary focus is operating in extreme temperatures or high pressures: A Teflon lip seal provides stability and performance where traditional elastomers would degrade or fail.

By understanding its unique material properties and construction, you can confidently specify a Teflon lip seal for your most demanding engineering challenges.

Summary Table:

| Key Characteristic | Performance Range / Capability |

|---|---|

| Material | Polytetrafluoroethylene (PTFE) |

| Temperature Range | -40°C to 220°C |

| Pressure Tolerance | Up to 250 Bar (3,600+ PSI) |

| Surface Speed | 10 to 40 m/s |

| Primary Advantage | Extreme chemical resistance & low friction |

Ready to solve your toughest sealing challenges?

For semiconductor, medical, laboratory, and industrial applications, KINTEK's precision-engineered PTFE seals deliver unmatched performance in extreme conditions. Our custom fabrication expertise ensures a perfect fit—from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific requirements and get a quote for reliable, high-performance sealing solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance