In terms of temperature resilience, Polytetrafluoroethylene (PTFE) operates in a class far beyond most standard elastomers. While common materials like Nitrile have a functional ceiling around 100°C (212°F), PTFE maintains its integrity and performance across a vast spectrum, from cryogenic lows of -200°C (-328°F) up to continuous high-heat environments of 260°C (500°F). This exceptionally wide operational window makes it a default choice for applications involving extreme thermal cycling.

The core issue is not simply that PTFE has a wider temperature range, but that it uniquely combines elite high-heat stability, unparalleled cryogenic performance, and near-total chemical inertness. This combination solves problems that no single standard elastomer can address.

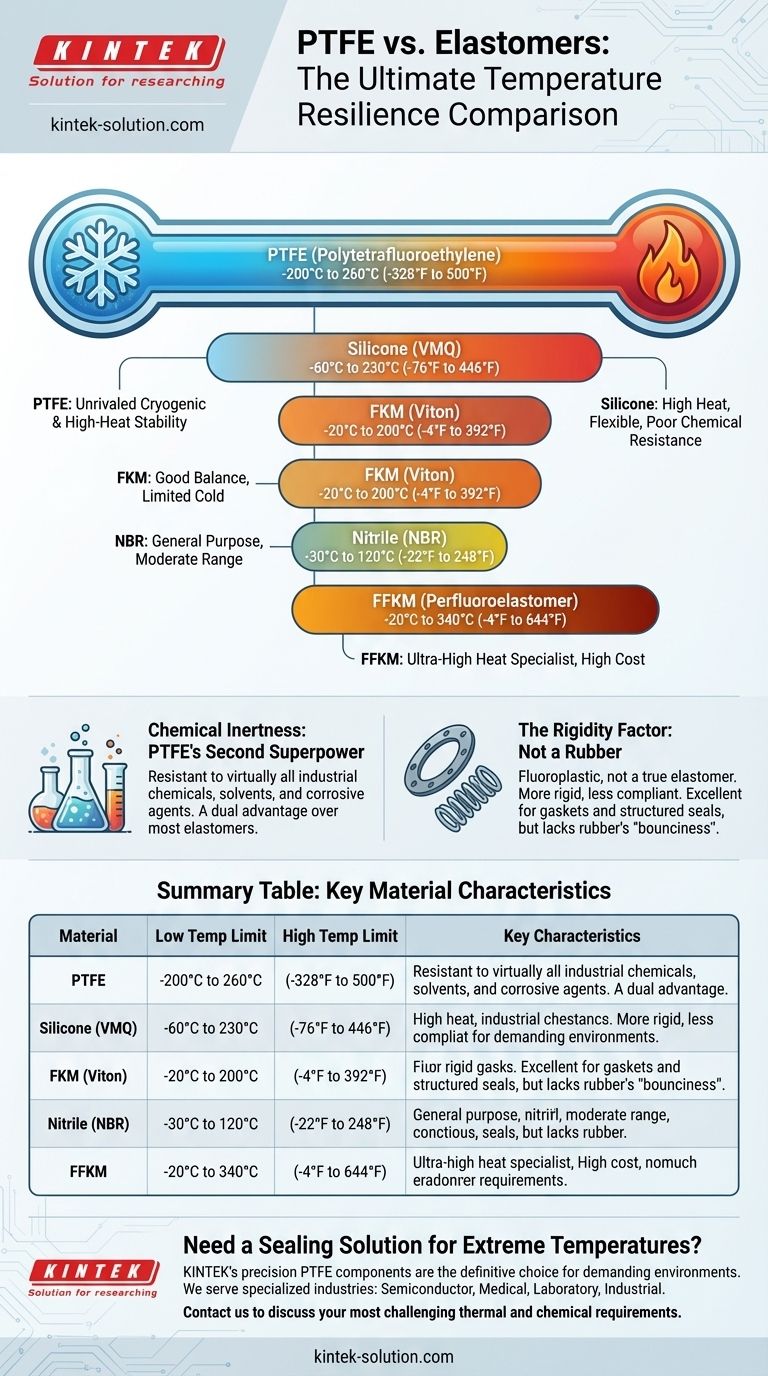

A Tale of Two Extremes: PTFE's Unmatched Thermal Range

The defining characteristic of PTFE is its ability to perform reliably at both ends of the temperature spectrum, where traditional elastomers would fail catastrophically.

Dominance in High Temperatures

PTFE provides a continuous service temperature of approximately 260°C (500°F). This comfortably exceeds the limits of most common industrial elastomers.

For instance, Fluoroelastomer (FKM/Viton) typically peaks around 200°C (392°F), while Silicone maxes out near 230°C (446°F). This makes PTFE a more robust solution for demanding high-heat applications.

Unrivaled Cryogenic Performance

This is where PTFE truly distances itself from the competition. It remains functional and avoids brittleness at temperatures as low as -200°C (-328°F).

In contrast, most elastomers like Nitrile or EPDM become brittle and lose their sealing properties well before -45°C (-49°F). This makes PTFE essential for cryogenic fluid transfer, aerospace, and deep-space applications.

How Other Materials Compare

Understanding the limits of other materials clarifies precisely where PTFE fits into an engineering decision. Each material occupies a specific performance niche.

Standard-Duty: NBR and EPDM

Nitrile (NBR) and EPDM are workhorse materials for general-purpose applications. Their temperature ranges are comparatively narrow, typically between -30°C to 120°C for NBR and -45°C to 150°C for EPDM. They offer excellent value within these moderate bounds.

High-Heat Specialists: Silicone (VMQ) and FKM (Viton)

Silicone and FKM are often selected when heat resistance beyond NBR or EPDM is required. Silicone can match PTFE's high-temperature performance, but it lacks PTFE's broad chemical resistance.

FKM offers a good balance of heat (up to 200°C) and chemical resistance, but it cannot handle the extreme cold that PTFE endures.

The Ultra-High Heat Contender: FFKM

Perfluoroelastomers (FFKM) are one of the few materials that can exceed PTFE's upper temperature limit, with some grades performing up to 340°C (644°F).

However, this top-end performance comes at the cost of inferior low-temperature capability and significantly higher material cost.

Understanding the Trade-offs

Temperature is a critical variable, but it is never the only factor. The mechanical properties and application environment are equally important.

The Rigidity Factor

It's crucial to recognize that PTFE is a fluoroplastic, not a true elastomer. It is significantly more rigid and less compliant than materials like Silicone or NBR.

This means that while it is an excellent material for gaskets or structured seals, it lacks the "bounciness" or memory of rubber, which can be critical for certain dynamic sealing applications.

Chemical Inertness: PTFE's Second Superpower

PTFE's thermal stability is matched by its near-total chemical inertness. It is resistant to virtually all industrial chemicals, solvents, and corrosive agents.

This dual resistance is often why it is chosen. An application involving both high temperatures and aggressive chemicals will almost always point toward PTFE over materials like Silicone, which have poor chemical compatibility.

PTFE Variations and Reinforcements

Pure PTFE is not the only option. Reinforcing PTFE with fillers like carbon or stainless steel (RPTFE) can slightly alter its properties, in some cases extending the upper temperature limit to 288°C (550°F) at the expense of some low-temperature capability.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary operational goal.

- If your primary focus is extreme cold (cryogenic) combined with high heat: PTFE is the definitive and often only choice due to its unparalleled operational range.

- If your primary focus is only high heat (up to 230°C) and you need more sealing flexibility: Silicone (VMQ) is a strong, more compliant alternative, provided chemical exposure is not severe.

- If your primary focus is extreme heat above 260°C (500°F): Perfluoroelastomers (FFKM) are the necessary upgrade, but expect compromises in low-temperature performance and cost.

- If your primary focus is a moderate temperature range in a general-purpose application: Standard elastomers like Nitrile (NBR) or EPDM offer the best balance of sealing performance and cost-effectiveness.

Ultimately, selecting the right material depends on a clear-eyed assessment of your entire operational environment, not just its temperature.

Summary Table:

| Material | Low Temp Limit | High Temp Limit | Key Characteristics |

|---|---|---|---|

| PTFE | -200°C (-328°F) | 260°C (500°F) | Extreme thermal range, chemical inertness, rigid |

| Silicone (VMQ) | -60°C (-76°F) | 230°C (446°F) | Flexible, good heat resistance, poor chemical resistance |

| FKM (Viton) | -20°C (-4°F) | 200°C (392°F) | Good heat/chemical balance, limited low-temp performance |

| Nitrile (NBR) | -30°C (-22°F) | 120°C (248°F) | Cost-effective, general purpose, moderate range |

| FFKM | -20°C (-4°F) | 340°C (644°F) | Ultra-high heat specialist, very high cost |

Need a Sealing Solution for Extreme Temperatures?

When your application demands performance from cryogenic conditions to high-heat environments, KINTEK's precision PTFE components are the definitive choice. We manufacture custom PTFE seals, liners, and labware that deliver the unparalleled thermal resilience and chemical inertness detailed in this article.

We serve specialized industries where failure is not an option:

- Semiconductor processing equipment

- Medical and life science devices

- Laboratory and analytical instrumentation

- Industrial manufacturing

Our expertise in custom fabrication ensures you get the right solution, from prototypes to high-volume production.

Contact KINTEB today to discuss how our PTFE components can solve your most challenging thermal and chemical requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of Teflon Bellow Mechanical Seals? Achieve Unmatched Reliability in Harsh Environments

- What types of products can be made from PTFE sheets in the chemical industry? | Gaskets, Liners & Seals

- How do PTFE coatings benefit industrial manufacturing? Enhance Equipment Life & Efficiency

- How are PTFE bellow seals affected by environmental factors? Discover Their Exceptional Resilience

- What are the two main methods used to manufacture PTFE gaskets? Ensure Optimal Sealing Performance

- What are the different types of PTFE seals? Choose the Right Seal for Your Application

- How are PTFE sheets utilized in the electrical industry? For Superior Insulation and Signal Integrity

- Are PTFE flange gaskets customizable? Tailor Your Sealing Solution for Peak Performance