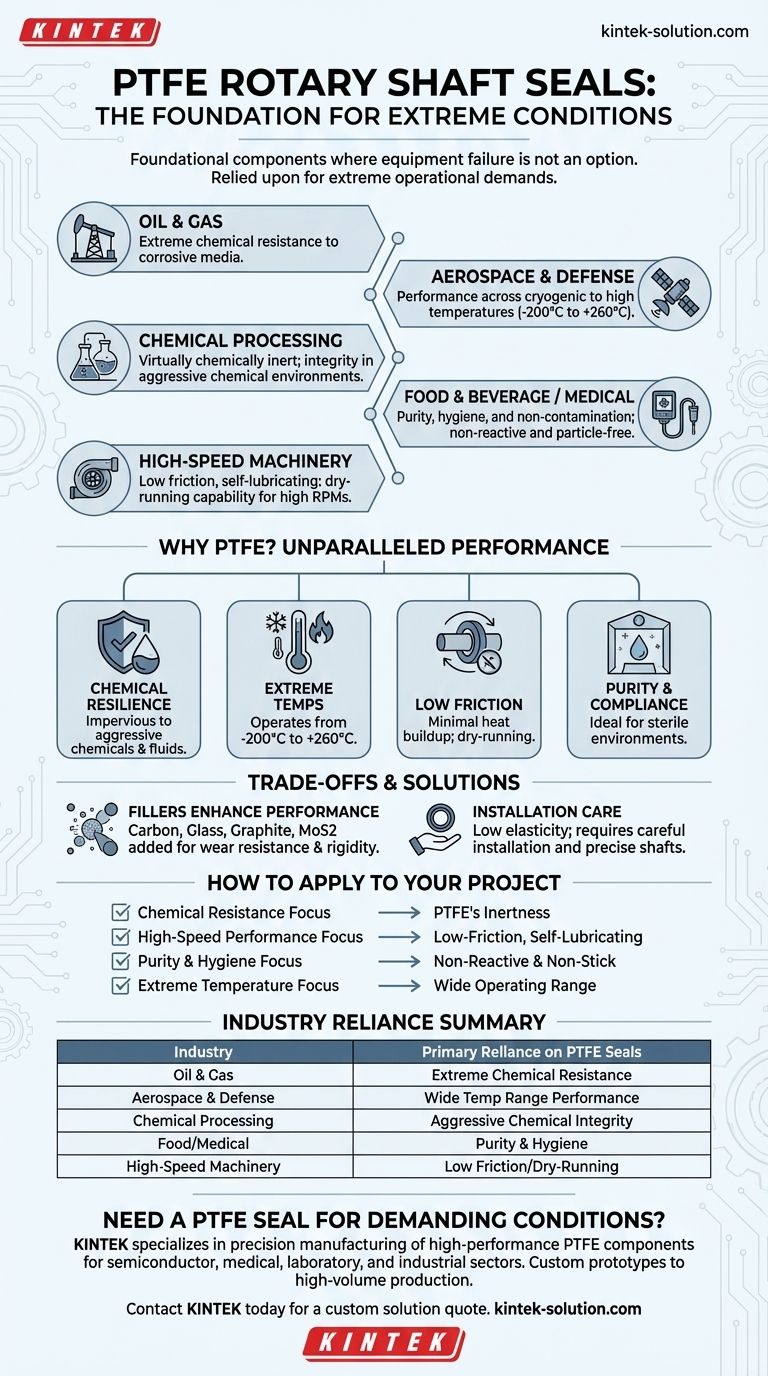

PTFE rotary shaft seals are foundational components in any industry where equipment failure is not an option. They are most heavily relied upon in sectors such as oil and gas, aerospace and defense, chemical processing, food and beverage, and medical device manufacturing due to their unique ability to perform under extreme operational demands.

The core reason specific industries mandate PTFE seals is not arbitrary; it's a direct response to harsh operating conditions. These seals are engineered to withstand aggressive chemicals, extreme temperatures, and high rotational speeds where conventional elastomer seals would rapidly degrade and fail.

Why These Industries Depend on PTFE Seals

The selection of a sealing material is a critical engineering decision. Industries turn to Polytetrafluoroethylene (PTFE) when performance requirements exceed the capabilities of standard materials like rubber. The material's distinct properties solve specific, high-stakes challenges.

Resilience in Aggressive Chemical Environments

PTFE is virtually chemically inert. This property makes it indispensable in applications involving corrosive or aggressive media.

Industries like chemical processing and oil and gas handle fluids that would quickly break down conventional seals, leading to dangerous leaks. PTFE's molecular structure allows it to maintain its integrity, ensuring operational safety and longevity.

Performance Across Extreme Temperature Ranges

Standard sealing materials have a limited thermal operating window. PTFE, however, performs reliably across a vast temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This makes it essential for aerospace and defense applications, which can involve cryogenic fuels on one end and extreme engine heat on the other. It's also critical in many industrial manufacturing processes.

Reliability in High-Speed and Dry-Running Applications

PTFE has an exceptionally low coefficient of friction, giving it self-lubricating or "non-stick" properties. This is crucial for high-speed rotating equipment.

In motorsports, screw compressors, and pumps, high rotational speeds generate significant frictional heat. PTFE seals minimize this heat buildup, reducing wear and allowing for dry-running capabilities that would destroy other seal types.

Purity and Compliance for Sensitive Applications

Contamination is a critical failure point in certain industries. PTFE is non-reactive and does not shed particles, making it ideal for sterile or ultra-clean environments.

This is non-negotiable in food and dairy, medical device manufacturing, and semiconductor manufacturing. In these fields, any contamination from the seal could compromise the final product, leading to significant safety and financial consequences.

Understanding the Trade-offs and Solutions

While PTFE offers unparalleled performance in specific areas, it's not a universal solution. Understanding its limitations is key to proper application.

The Role of Fillers in Enhancing Performance

Virgin PTFE can be relatively soft and susceptible to wear and deformation under load (a phenomenon known as "creep"). To counteract this, it is often blended with fillers.

Common fillers like carbon, glass, graphite, or MoS2 (Molybdenum disulfide) are added to the PTFE base. These materials dramatically improve wear resistance, thermal conductivity, and structural rigidity, tailoring the seal's properties to specific demands like high pressure or abrasive media.

Installation and Elasticity Considerations

Unlike rubber, PTFE has very low elasticity. It does not have the same "memory" or bounce-back as elastomeric materials.

This means installation requires greater care to avoid damaging the seal lip. It also makes PTFE seals less forgiving of shaft imperfections or runout compared to more flexible alternatives.

How to Apply This to Your Project

The decision to use a PTFE seal should be driven entirely by the operational demands of your equipment.

- If your primary focus is chemical resistance: PTFE's inertness is the deciding factor, making it essential for equipment in chemical processing or oil and gas.

- If your primary focus is high-speed performance: The low-friction, self-lubricating properties are critical for high-RPM machinery like compressors, blowers, and performance vehicles.

- If your primary focus is purity and hygiene: The non-reactive and non-stick nature of PTFE is mandatory for any application in the food, medical, or semiconductor industries.

- If your primary focus is extreme temperatures: PTFE's exceptionally wide operating temperature range makes it the default choice for aerospace, defense, and specialized industrial manufacturing.

Ultimately, selecting a PTFE rotary shaft seal is a strategic engineering decision based on its unique ability to maintain integrity in environments that guarantee the failure of other materials.

Summary Table:

| Industry | Primary Reliance on PTFE Seals |

|---|---|

| Oil & Gas | Extreme chemical resistance to corrosive media |

| Aerospace & Defense | Performance across cryogenic to high temperatures |

| Chemical Processing | Integrity in aggressive chemical environments |

| Food & Beverage / Medical | Purity, hygiene, and non-contamination |

| High-Speed Machinery | Low friction and dry-running capability |

Need a PTFE Seal for Demanding Conditions?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including rotary shaft seals, for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a custom prototype or a high-volume production run, our expertise ensures a sealing solution that delivers reliability under extreme pressure, temperature, and chemical challenges.

Contact KINTEK today to discuss your specific application and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support