In environments with corrosive or reactive substances, PTFE-lined pipes have a significantly longer operational lifespan than standard steel pipes. The inert nature of the PTFE (Polytetrafluoroethylene) lining acts as a protective shield, preventing the chemical degradation and corrosion that are the primary causes of failure in unprotected steel.

The core difference in lifespan comes down to one factor: protection. Standard steel is vulnerable to direct attack from corrosive materials, while a PTFE lining creates an impassable barrier, preserving the structural integrity of the steel pipe for much longer.

The Core Problem: Why Standard Steel Pipes Fail

Understanding why PTFE-lined pipes excel requires first understanding the inherent vulnerabilities of standard steel when used in demanding industrial applications.

Vulnerability to Corrosion

Standard steel, an alloy of iron and carbon, is highly susceptible to oxidation, or rust. When exposed to moisture and oxygen, especially in the presence of chemicals that accelerate the process, the steel begins to degrade, compromising its structural strength.

Susceptibility to Chemical Attack

Beyond general corrosion, many industrial processes involve highly acidic or alkaline substances. These chemicals can directly attack and dissolve the steel, leading to thinning walls, leaks, and eventual catastrophic failure.

How PTFE Lining Extends Service Life

A PTFE-lined pipe combines the structural strength of steel with the chemical resistance of a fluoropolymer. This creates a system that is superior to either material on its own.

Creating a Non-Reactive Barrier

PTFE is one of the most chemically inert substances known. It does not react with acids, bases, or solvents. By lining the interior of a steel pipe with PTFE, you effectively isolate the steel from the corrosive material being transported.

Preventing Degradation and Failure

This protective lining directly mitigates the failure points of standard steel. It prevents the chemical reactions that cause corrosion and degradation, dramatically extending the pipeline's lifespan and reducing the risk of leaks or bursts.

The Tangible Benefits of a Longer Lifespan

The longevity of PTFE-lined pipes translates into significant operational and financial advantages over time.

Reduced Replacement Costs

While the initial investment may be higher, the extended service life means fewer replacement cycles. This results in lower long-term costs for materials, labor, and specialized installation equipment.

Minimized Operational Downtime

Pipe failures lead to processing halts, which can be extraordinarily expensive. The reliability of PTFE-lined systems ensures greater operational uptime and predictable maintenance schedules.

Enhanced Safety and Compliance

Preventing catastrophic failures is critical when handling hazardous substances. The integrity of PTFE lining mitigates the risk of dangerous leaks, protecting personnel, the environment, and ensuring compliance with safety regulations.

Understanding the Trade-offs

Choosing the right piping material requires an objective look at the initial investment versus the long-term operational reality.

Higher Initial Investment

PTFE-lined pipe is a specialized product with a higher upfront cost than standard carbon steel pipe. This initial expense must be weighed against the total cost of ownership over the lifetime of the system.

Not a Universal Solution

For applications involving non-corrosive substances like water or certain oils in a stable environment, the benefits of PTFE lining may not justify the cost. In these cases, standard steel or other materials can be a perfectly suitable and more economical choice.

Making the Right Choice for Your Application

Your decision should be based on the chemical nature of the media you are transporting and your long-term operational goals.

- If your primary focus is transporting corrosive chemicals, acids, or high-purity substances: PTFE-lined pipe is the superior choice for ensuring long-term safety, reliability, and minimizing total ownership cost.

- If your primary focus is cost-efficiency for non-corrosive, non-reactive materials: Standard steel pipe is often the most practical and economical solution.

Ultimately, selecting the correct piping system is an exercise in balancing upfront cost against the significant long-term risks of chemical attack and corrosion.

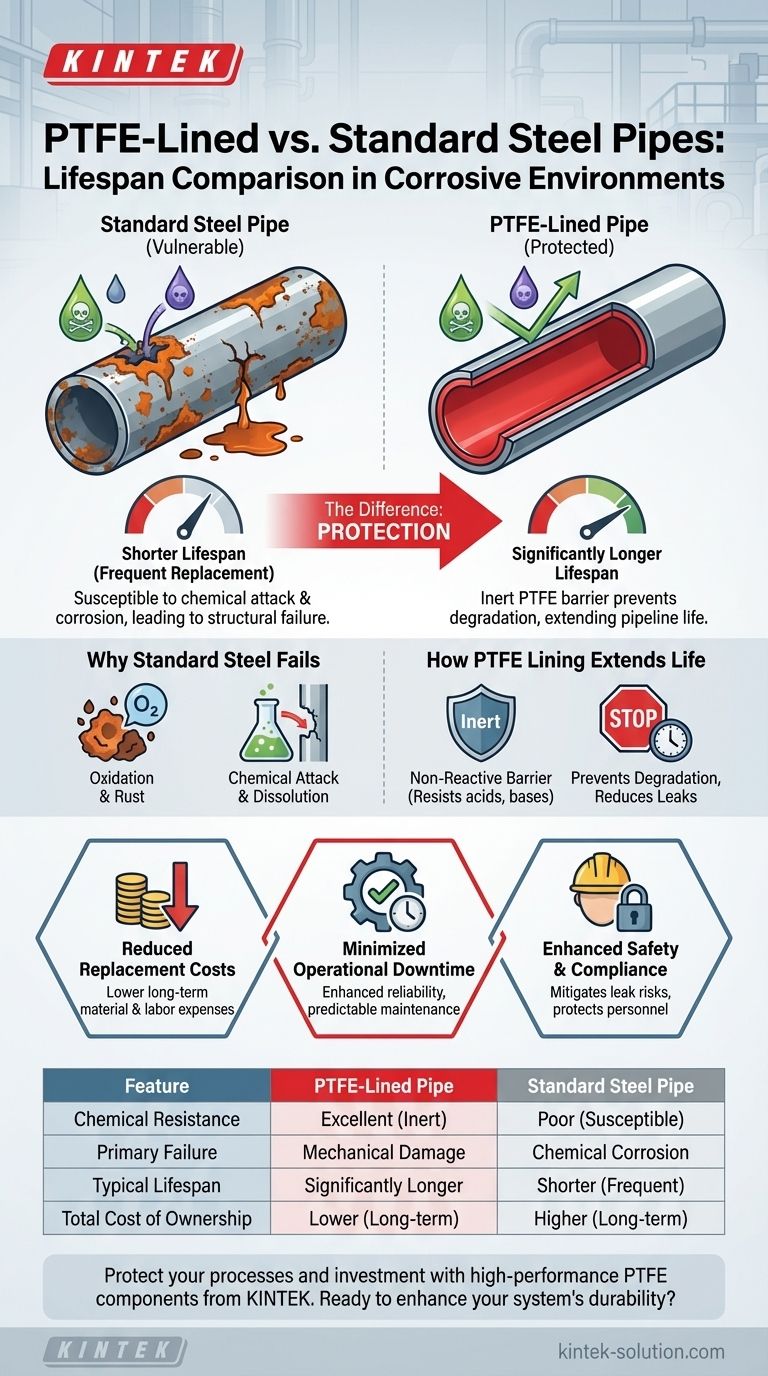

Summary Table:

| Feature | PTFE-Lined Pipe | Standard Steel Pipe |

|---|---|---|

| Chemical Resistance | Excellent (inert to most acids, bases, solvents) | Poor (susceptible to corrosion) |

| Primary Failure Cause | Mechanical wear or damage to lining | Chemical corrosion and degradation |

| Typical Lifespan | Significantly longer in corrosive service | Shorter, requires frequent replacement |

| Best For | Corrosive, high-purity, or reactive chemicals | Non-corrosive media (e.g., water, oils) |

| Total Cost of Ownership | Lower long-term (higher upfront cost) | Higher long-term (lower upfront cost) |

Protect your processes and investment with high-performance PTFE components from KINTEK.

Choosing the right material is critical for the longevity and safety of your piping systems. KINTEK specializes in manufacturing precision PTFE components—including custom-lined pipes, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We partner with you from prototype to high-volume production to deliver solutions that:

- Extend Equipment Lifespan: Our PTFE linings act as an impervious barrier against corrosive chemicals.

- Reduce Downtime: Enhance reliability with components built for demanding environments.

- Lower Total Cost of Ownership: Minimize replacement cycles and unplanned maintenance.

Ready to enhance your system's durability? Contact our experts today to discuss your specific application and receive a customized solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What material is used to make PTFE bushings? The Ultimate Guide to PTFE's Performance

- How do different glass weave styles affect phase response in RF PCBs? Ensure Phase Coherence for High-Frequency Designs

- What tips can help in using Teflon sheets effectively? Achieve Flawless Heat Press Results

- How does PTFE's low friction performance benefit industrial applications? Enable Clean, Reliable Movement Without Lubricants

- What are the advantages of CNC machining for Teflon/PTFE? Achieve High Precision and Consistency

- What are the three main factors to consider when selecting ball valve seat materials? Ensure System Reliability

- Why do PTFE gaskets have a long service life? Achieve Unmatched Sealing Durability & Cost Savings

- What makes PTFE Teflon washers suitable for electrical applications? Superior Insulation for Harsh Environments