Polytetrafluoroethylene (PTFE) leverages its exceptionally low friction to solve one of industry's most persistent challenges: enabling smooth, reliable mechanical movement in environments where traditional lubrication is not an option. Its self-lubricating and non-stick properties reduce wear, minimize energy consumption, and prevent contamination, making it a critical material for high-performance components in sectors ranging from pharmaceuticals to civil engineering.

The true value of PTFE's low friction is its ability to create self-lubricating systems that operate cleanly and reliably in harsh environments—from food processing plants to chemical reactors—where conventional lubricants would fail or cause contamination.

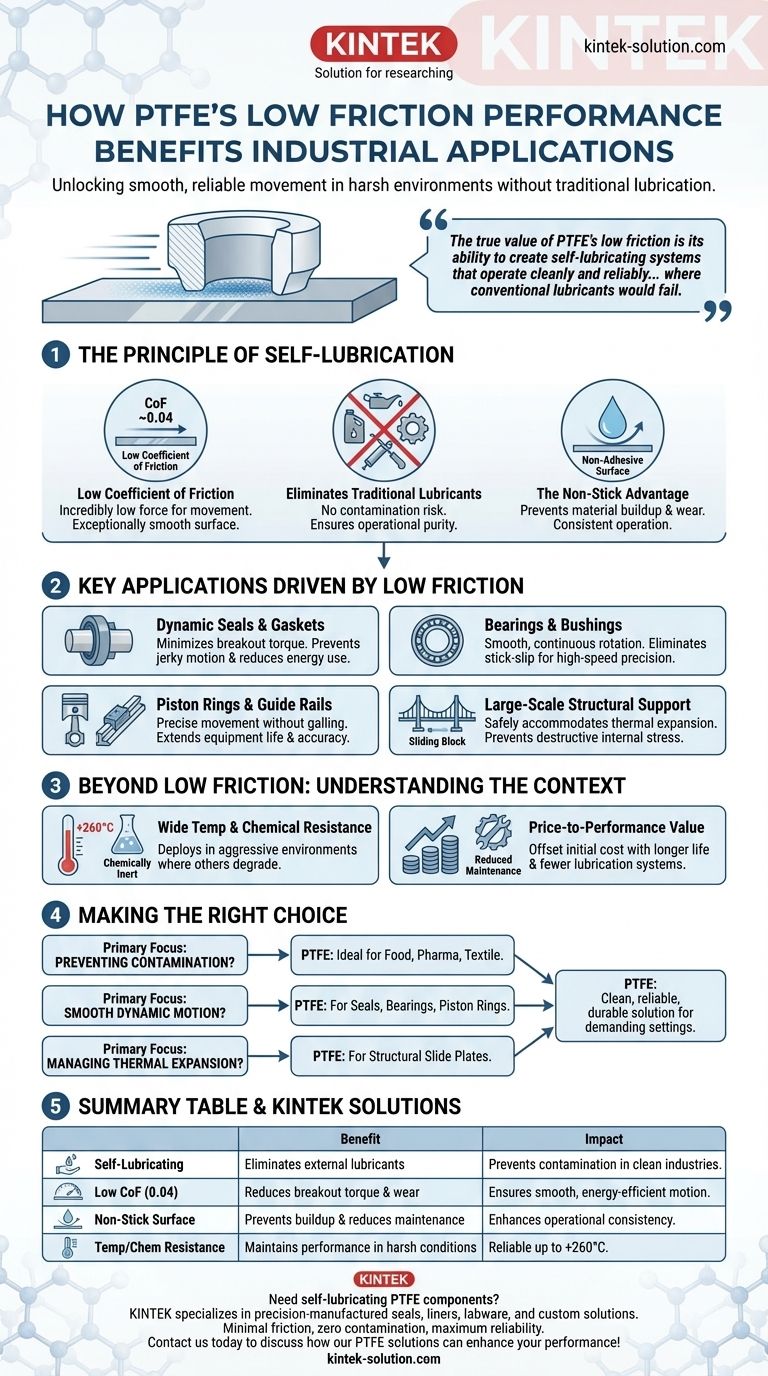

The Principle of Self-Lubrication

The core benefit of PTFE stems from its inherent ability to function without external lubricants like oil or grease. This is a direct result of its molecular structure, which creates an incredibly smooth, low-energy surface.

What is a Low Coefficient of Friction?

PTFE has one of the lowest coefficients of friction of any known solid, with values as low as 0.04. This means the force required to move a PTFE surface against another is exceptionally small.

This inherent slipperiness is why PTFE components can slide against each other or other materials with minimal resistance or heat generation.

Eliminating Traditional Lubricants

In many industries, traditional lubricants are a liability. They can contaminate products in food, pharmaceutical, or textile manufacturing, or they can be dissolved by solvents in chemical processing.

PTFE parts require no external lubrication, completely removing the risk of contamination and ensuring operational purity.

The "Non-Stick" Advantage

Low friction is directly linked to PTFE's non-adhesive, or "non-stick," nature. This property prevents other materials from sticking to its surface.

In industrial machinery, this reduces wear on mating surfaces, prevents buildup that could hinder performance, and ensures smooth, consistent operation over the component's lifespan.

Key Applications Driven by Low Friction

The self-lubricating quality of PTFE makes it the material of choice for a wide array of dynamic and static applications where minimizing resistance is critical.

Dynamic Seals and Gaskets

For seals in moving parts, such as in pumps or hydraulic systems, low friction is essential. It minimizes the initial force required for movement, known as breakout torque.

This prevents jerky motion, reduces wear on the seal, and lowers the energy needed to operate the equipment.

Bearings and Bushings

PTFE is used to create bearings and bushings for high-speed or sensitive applications. These components allow for smooth, continuous rotation or linear movement without the stick-slip effect often seen with other materials.

This is particularly valuable in machinery where consistent performance is paramount.

Piston Rings and Guide Rails

In components like piston rings and machine tool rails, PTFE ensures precise and effortless movement. Its self-lubricating nature prevents galling and seizure between metal parts that are in constant contact.

This leads to greater accuracy, longer equipment life, and reduced maintenance requirements.

Large-Scale Structural Support

In civil engineering, PTFE is used in sliding blocks for bridges, pipelines, and large buildings.

These pads allow massive structures to safely expand and contract with temperature changes, sliding smoothly against each other instead of building up destructive internal stress.

Understanding the Trade-offs and Context

While its low friction is a defining feature, PTFE's overall effectiveness comes from a combination of properties. Understanding this context is key to its proper application.

More Than Just Low Friction

PTFE's utility is amplified by its other characteristics. It has an extremely wide operating temperature range (up to +260°C), is almost completely chemically inert, and does not absorb water.

This unique combination allows its low-friction benefits to be deployed in chemically aggressive and high-temperature environments where most other materials would degrade.

Price-to-Performance Value

While not the cheapest polymer, PTFE often provides the best price-to-performance ratio for demanding applications.

The initial material cost is frequently offset by reduced maintenance, longer component life, and the elimination of complex lubrication systems.

Making the Right Choice for Your Application

Choosing PTFE is a strategic decision based on the specific constraints and goals of your operating environment.

- If your primary focus is preventing contamination: PTFE is the ideal choice for self-lubricating parts in food, pharmaceutical, or textile manufacturing.

- If your primary focus is smooth dynamic motion: Use PTFE for seals, piston rings, and bearings to minimize friction, reduce wear, and eliminate jerky startups.

- If your primary focus is managing thermal expansion: PTFE slide plates provide a low-friction interface for large civil and industrial structures, preventing stress buildup.

Ultimately, PTFE's low-friction performance provides a clean, reliable, and durable solution for movement in the most demanding industrial settings.

Summary Table:

| Key Benefit | Industrial Impact |

|---|---|

| Self-Lubricating | Eliminates need for external lubricants, preventing contamination in food, pharma, and chemical processing. |

| Low Coefficient of Friction (0.04) | Reduces breakout torque, minimizes wear, and ensures smooth motion in seals, bearings, and piston rings. |

| Non-Stick Surface | Prevents material buildup, reduces maintenance, and enhances operational consistency in machinery. |

| Wide Temperature & Chemical Resistance | Maintains performance in harsh environments (up to 260°C) where other materials fail. |

Need self-lubricating PTFE components for your industrial application?

At KINTEK, we specialize in precision-manufactured PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates with minimal friction, zero contamination, and maximum reliability—from prototypes to high-volume orders.

Contact us today to discuss how our PTFE solutions can enhance your performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support