To use a Teflon sheet effectively, you must go beyond simply placing it on your project. Success depends on selecting the right size, ensuring it lays perfectly flat to prevent movement, keeping it immaculately clean, and understanding how it can subtly alter the heat transfer process.

Your Teflon sheet is an essential protective barrier for both your garment and your heat press. However, its true value is only realized when you master its use to ensure consistency and prevent common errors like print shifting or heat variation.

The Fundamental Role of a Teflon Sheet

A Teflon sheet acts as a reusable, heat-resistant guard during the heat transfer process. Its primary functions are to protect your investments: the materials you're printing on and the equipment you're using.

Protecting Your Garment

The sheet distributes heat evenly across the transfer area. This is critical for preventing scorching or discoloration on delicate fabrics that are sensitive to direct, high heat.

Protecting Your Heat Press

It creates a non-stick barrier between your design and the upper platen of your press. This prevents inks, adhesives, and other residues from building up on your equipment, ensuring clean operation for future projects.

Ensuring a Non-Stick Surface

The slick surface of Teflon prevents transfers from sticking to the heat source. This helps you avoid smudges and ensures the design remains crisp and clear upon completion.

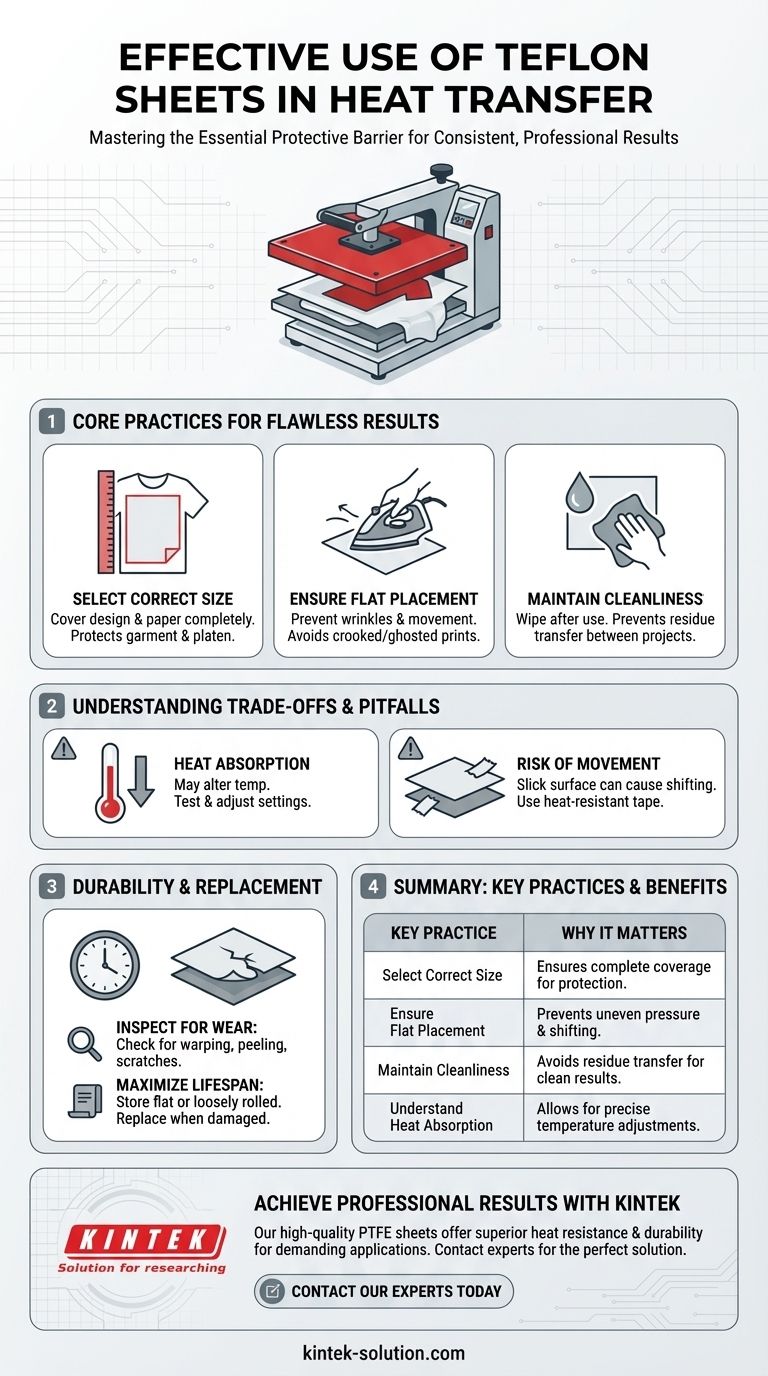

Core Practices for Flawless Results

Simple habits can make the difference between an amateur and a professional-looking final product. Integrating these practices into your workflow is essential.

Select the Correct Size

Your Teflon sheet should always be large enough to cover the entire design and transfer paper area. This ensures complete protection for both the garment and the platen.

Ensure a Perfectly Flat Placement

Before pressing, make certain the sheet is completely flat and free of wrinkles. Any bumps or folds can create uneven pressure, and a loose sheet can move during pressing, resulting in a crooked or "ghosted" print.

Maintain Impeccable Cleanliness

Wipe the sheet down with a damp cloth after each use to remove any residual ink or adhesive. For more stubborn stains, use a mild soap and water solution, then dry it completely. A clean sheet prevents residue from old projects from transferring to new ones.

Handle Safely When Hot

Always use heat-resistant gloves when handling a Teflon sheet immediately after a press. It will be extremely hot and can cause serious burns.

Understanding the Trade-offs and Pitfalls

While highly beneficial, Teflon sheets are not without their potential issues. Being aware of them allows you to compensate and avoid common mistakes.

Potential for Heat Absorption

A Teflon sheet can absorb a small amount of heat, which may slightly alter the temperature that reaches your transfer. You may need to run test presses and adjust your temperature or duration settings accordingly to achieve optimal results.

The Risk of Transfer Movement

The very property that makes Teflon non-stick can also be a drawback. If your transfer paper is not properly secured, the slick surface of the sheet can allow it to shift during the pressing process.

The "Ghosting" Effect in Sublimation

Some users report issues with "ghosting"—a faint, shadowy second image—when using Teflon sheets for dye-sublimation. This is often caused by the transfer paper shifting slightly as the press is opened. Using heat-resistant tape to secure your design is critical.

Durability and When to Replace

Teflon sheets are designed for repeated use, but they do not last forever. Regular inspection is key to maintaining quality.

Inspecting for Wear and Tear

Check your sheet regularly for signs of degradation. Look for significant discoloration, warping, peeling, or scratches that could affect its non-stick properties or heat distribution.

Maximizing Lifespan

With proper cleaning and storage (ideally flat or loosely rolled), you can significantly extend the life of your sheet. Once you see physical damage, it's time to replace it to avoid compromising your work.

Applying This to Your Project

Your approach should be guided by your primary goal for each specific project.

- If your primary focus is protecting delicate fabrics: Use the sheet every time to create a buffer that prevents scorching and ensures even heat distribution.

- If your primary focus is preventing ink bleed-through: Always place the sheet over your transfer to shield the upper heat platen from contamination.

- If your primary focus is high-detail sublimation: Be extra vigilant about taping your transfer securely to the garment to prevent any movement and avoid ghosting.

By treating your Teflon sheet as a precision tool rather than a simple accessory, you will achieve more consistent and professional results.

Summary Table:

| Key Practice | Why It Matters |

|---|---|

| Select Correct Size | Ensures complete coverage of design and transfer paper for full protection. |

| Ensure Flat Placement | Prevents uneven pressure and print shifting for a crisp, aligned design. |

| Maintain Cleanliness | Avoids residue transfer between projects, ensuring a clean, non-stick surface. |

| Understand Heat Absorption | Allows for temperature/duration adjustments to achieve optimal transfer quality. |

Achieve consistent, professional results with precision-engineered PTFE sheets from KINTEK.

Our high-quality PTFE (Teflon®) sheets are manufactured for superior heat resistance, durability, and non-stick performance, making them ideal for the demanding environments of semiconductor, medical, laboratory, and industrial applications. Whether you need standard sizes or custom fabrication for prototypes or high-volume orders, KINTEK delivers the precision and reliability your process requires.

Contact our experts today to find the perfect PTFE solution for your heat press or specialized application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance