To be precise, PTFE bushings are made from a synthetic fluoropolymer called polytetrafluoroethylene (PTFE). This material is composed entirely of carbon and fluorine atoms, which form an exceptionally strong and stable molecular structure. While some bushings use pure, or "virgin," PTFE, many are made from a composite material where PTFE is blended with other fillers to enhance its mechanical properties.

The critical takeaway is not just the material's name, but its underlying chemistry. The incredibly strong carbon-fluorine bond is directly responsible for the unique combination of chemical inertness, temperature resistance, and low friction that makes PTFE an ideal material for bushings.

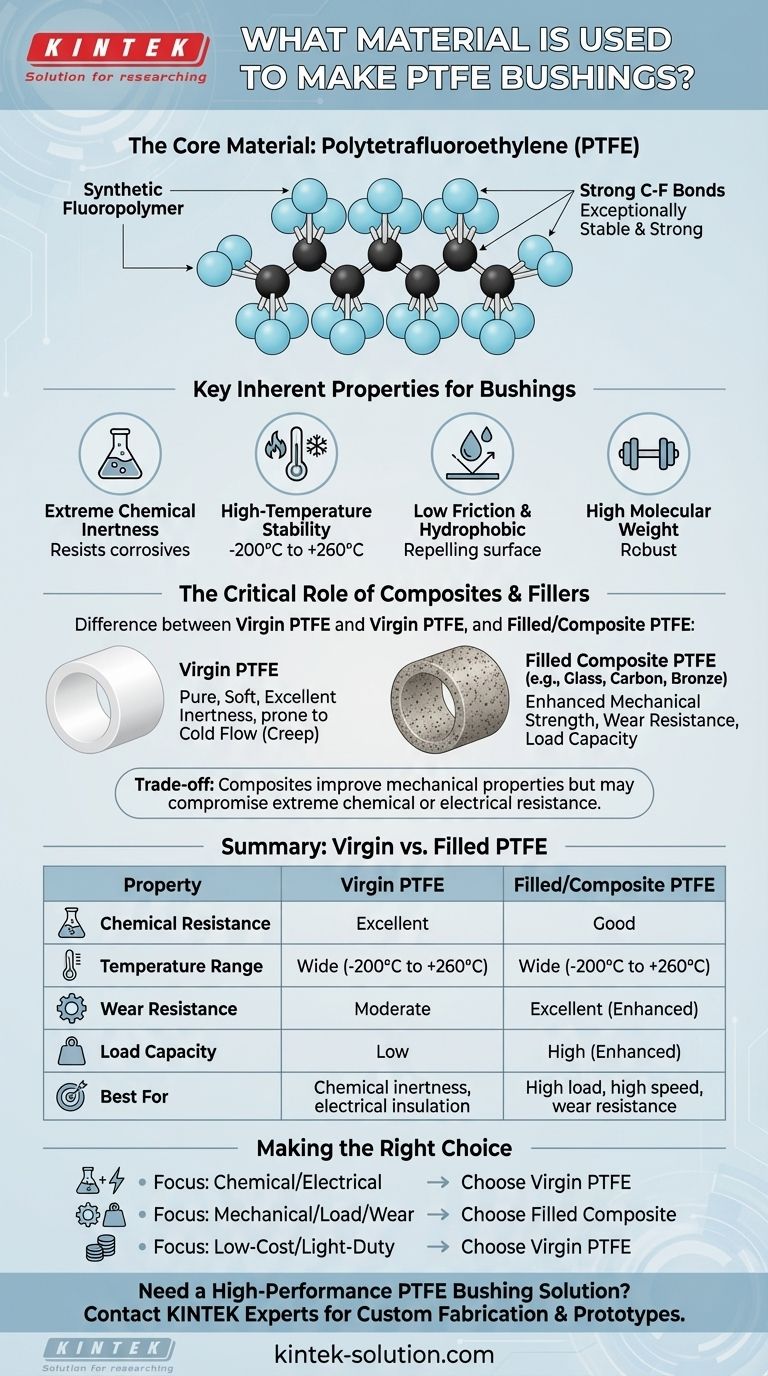

The Foundation: Understanding Polytetrafluoroethylene (PTFE)

To grasp why PTFE is so effective, we must look at its molecular structure. This structure dictates every one of its valuable physical properties.

A Synthetic Fluoropolymer

PTFE is not a naturally occurring substance. It is a man-made polymer—a large molecule made of repeating subunits—synthesized from tetrafluoroethylene gas.

The Core Chemical Structure

At its heart, PTFE consists of a long chain of carbon atoms. What makes it unique is that this carbon backbone is completely sheathed by fluorine atoms.

Each carbon atom is bonded to two fluorine atoms, and these carbon-fluorine (C-F) bonds are among the strongest known in organic chemistry. This arrangement creates a dense, stable, and non-reactive protective shell around the molecule.

Key Inherent Properties

This powerful molecular structure gives PTFE several defining characteristics. It is hydrophobic, meaning it repels water and will not absorb moisture. It also has a very high molecular weight, contributing to its robustness and stability as a solid material.

Why This Structure Matters for Bushings

The molecular properties of PTFE translate directly into high-performance characteristics that are ideal for a bushing—a component designed to reduce friction and wear between moving parts.

Extreme Chemical Inertness

The strong carbon-fluorine bonds make PTFE almost completely inert. It does not react with corrosive chemicals, acids, or bases, making it perfect for use in harsh industrial or chemical processing environments.

High-Temperature Stability

The same powerful bonds that resist chemical attack also resist thermal energy. This gives PTFE a wide operating temperature range and a high melting point, allowing it to function reliably in extreme heat and cold.

The Critical Role of Composites

While pure PTFE has excellent properties, it can be relatively soft. To improve its performance under mechanical stress, PTFE is often blended with fillers to create a composite material. Common fillers include glass fibers, carbon, graphite, or bronze, which significantly increase the bushing's wear resistance and load-bearing capacity.

Understanding the Trade-offs

No material is perfect. Acknowledging the limitations of PTFE is key to using it effectively and understanding why composite versions are so common.

Softness and Cold Flow (Creep)

The primary trade-off of virgin PTFE is its relative softness. Under a constant, heavy load, the material can slowly deform over time in a process known as "creep" or "cold flow."

Moderate Wear Resistance

In its pure form, PTFE's wear resistance is only moderate compared to harder engineering plastics or metals. For high-speed or high-load applications where durability is paramount, a filled composite is almost always required.

Making the Right Choice for Your Application

Your selection of a PTFE bushing depends entirely on the mechanical and environmental demands of your project.

- If your primary focus is extreme chemical resistance or electrical insulation: Choose a bushing made from virgin PTFE, as fillers can compromise these properties.

- If your primary focus is mechanical strength, load capacity, and wear resistance: Select a filled or composite PTFE bushing with a filler (like glass, carbon, or bronze) suited to your specific load and speed requirements.

- If your primary focus is a low-cost, low-friction solution for a light-duty application: Virgin PTFE is often a sufficient and economical choice.

By understanding the molecular foundation of PTFE, you can select a bushing not just by its name, but by its precise fitness for the task at hand.

Summary Table:

| Property | Virgin PTFE | Filled/Composite PTFE |

|---|---|---|

| Chemical Resistance | Excellent | Good (may vary with filler) |

| Temperature Range | Wide (-200°C to +260°C) | Wide (-200°C to +260°C) |

| Wear Resistance | Moderate | Excellent (Enhanced) |

| Load Capacity (Creep Resistance) | Low | High (Enhanced) |

| Best For | Chemical inertness, electrical insulation | High load, high speed, wear resistance |

Need a High-Performance PTFE Bushing Solution?

Understanding the chemistry of PTFE is the first step. Applying that knowledge to design and fabricate the perfect bushing for your specific application is where KINTEK excels. We specialize in manufacturing precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors.

Whether you require the ultimate chemical purity of virgin PTFE or the enhanced mechanical strength of a filled composite, our custom fabrication services—from prototypes to high-volume orders—ensure you get a component that delivers optimal performance, durability, and value.

Let's discuss your project requirements and engineer a solution that fits.

Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems