The primary advantages of CNC machining for Teflon (PTFE) are its ability to deliver high precision, excellent repeatability, and reduced material waste. Because PTFE is a soft, temperature-sensitive material prone to deformation, the computer-controlled environment of CNC is essential for managing its unique properties and producing complex, functional parts with the tight tolerances required by demanding industries.

While manual machining can handle the simplest PTFE components, CNC machining is the definitive method for transforming this challenging material into high-performance parts. It provides the necessary control to overcome PTFE's inherent weaknesses—like thermal expansion and softness—turning them into manageable variables rather than critical flaws.

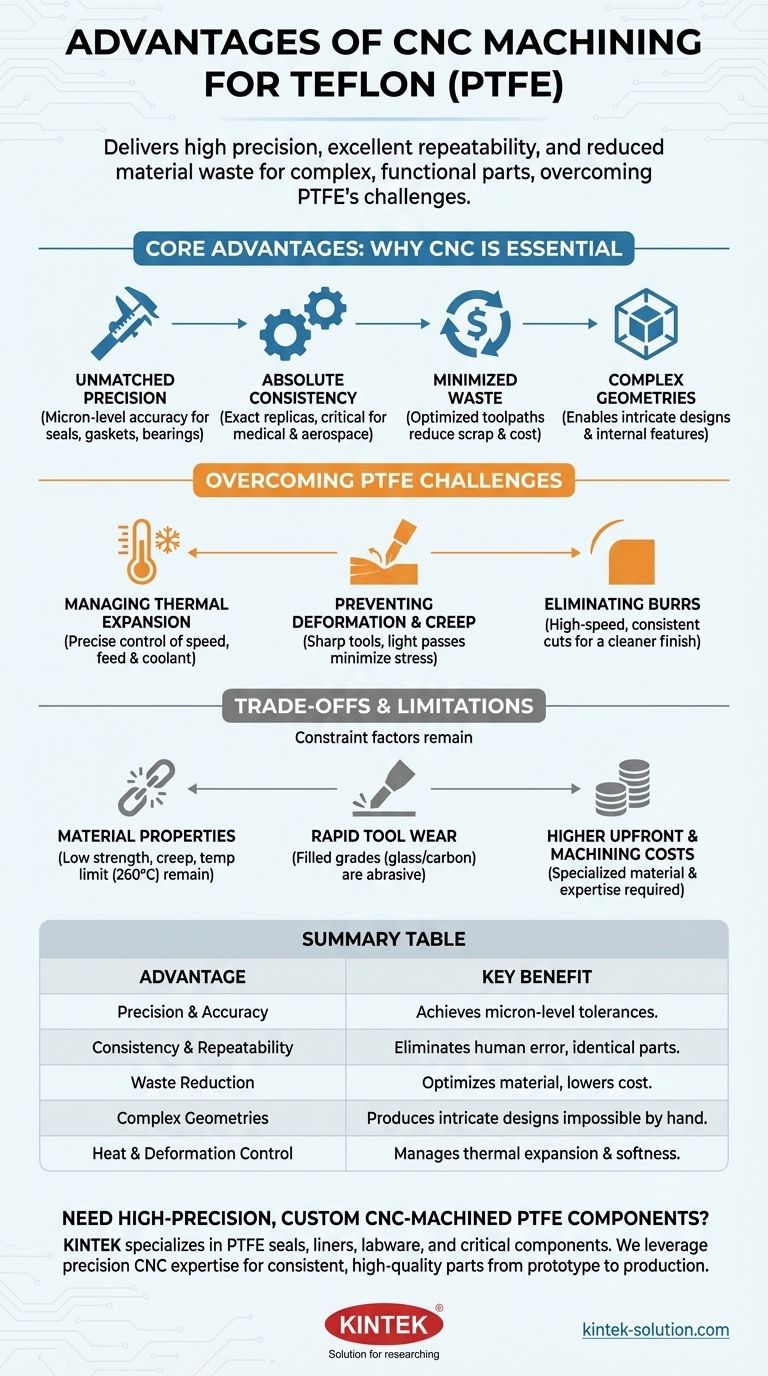

Why CNC is Essential for High-Performance PTFE Parts

The unique combination of properties that makes PTFE so valuable—its low friction, chemical inertness, and biocompatibility—also makes it notoriously difficult to machine. CNC technology directly addresses these challenges, making it the preferred method for nearly all critical applications.

Achieving Unmatched Precision

PTFE's softness means it can easily deform under the pressure of a cutting tool, making manual machining highly imprecise.

CNC systems use computer-guided movements to execute cuts with micron-level accuracy, ensuring that features like seals, gaskets, and bearings meet exact specifications.

Ensuring Absolute Consistency

For applications in the medical, aerospace, or semiconductor industries, part-to-part consistency is not just a goal; it's a requirement.

CNC machining guarantees that every component produced is an exact replica of the last. This eliminates the human error and variability inherent in manual processes.

Minimizing Material Waste

Raw PTFE material can be costly, and inefficient machining can quickly drive up project expenses.

By using optimized toolpaths, CNC programs ensure the most efficient use of the material, reducing the amount of scrap generated and lowering the overall cost per part.

Handling Complex Geometries with Ease

Modern components often feature intricate designs that are impossible to create by hand.

CNC machines, including milling, turning, and multi-axis systems, can execute complex operations to produce sophisticated parts with internal threads, curved surfaces, and other advanced features.

Overcoming Teflon's Inherent Machining Challenges

The real advantage of CNC machining is its ability to control the environment and cutting parameters to mitigate PTFE's most problematic behaviors.

Managing Thermal Expansion

PTFE has a high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. Heat generated during machining can easily ruin a part's dimensional accuracy.

A CNC process allows for precise control over cutting speeds, feed rates, and the application of coolant to manage heat buildup and maintain stability.

Preventing Deformation and Creep

The material's low mechanical strength makes it susceptible to deforming under cutting pressure or "creeping" (slowly deforming) if clamped too tightly.

CNC machining enables the use of extremely sharp tools and carefully programmed, light cutting passes that minimize stress on the material, preserving its structural integrity.

Eliminating Burrs for a Clean Finish

Because it is so soft, PTFE tends to form burrs (small, ragged edges) during cutting rather than chipping away cleanly.

The high-speed, consistent cuts of a CNC machine produce a much cleaner finish, significantly reducing the need for time-consuming secondary deburring operations.

Understanding the Trade-offs and Limitations

While powerful, CNC machining is not a magic bullet. The inherent properties of PTFE itself introduce constraints that even the most advanced technology cannot change.

Material Properties Remain a Constraint

CNC machining optimizes the manufacturing process, but it does not alter the fundamental nature of PTFE.

The final part will still have low mechanical strength, a tendency to creep under continuous load, and a limited operating temperature (typically up to 260°C). The part's design must account for these limitations.

The Risk of Rapid Tool Wear

While pure PTFE is soft, some filled grades (e.g., glass-filled or carbon-filled) are highly abrasive and can cause rapid wear on cutting tools.

This requires the use of specialized, durable tooling and must be factored into the overall cost and maintenance schedule of a project.

Higher Upfront and Machining Costs

Compared to common plastics or metals, both the raw PTFE material and the specialized expertise required to machine it correctly can lead to higher costs.

While CNC reduces waste, the complexity of the setup and the need for skilled operators mean it is often a more significant investment than simpler manufacturing methods.

Is CNC Machining Right for Your PTFE Application?

Choosing the right manufacturing process depends entirely on the requirements of your final part.

- If your primary focus is critical precision and repeatability (e.g., aerospace, medical): CNC machining is non-negotiable to meet tight tolerances and ensure the reliability of components like seals, insulators, and medical implants.

- If your primary focus is complex part geometry: CNC is the only viable method for producing intricate designs with features that are impossible to achieve manually.

- If your primary focus is high-volume production: CNC's automation, speed, and consistency make it the most efficient and cost-effective solution for manufacturing identical parts at scale.

- If your primary focus is a simple prototype with loose tolerances: While manual machining might seem feasible, the superior control and finish from CNC often provide a better result even for basic jobs.

By leveraging CNC's precise control, you transform Teflon's challenging properties into a predictable and reliable manufacturing process for mission-critical components.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Precision & Accuracy | Achieves micron-level tolerances for complex parts. |

| Consistency & Repeatability | Eliminates human error, ensuring every part is identical. |

| Waste Reduction | Optimized toolpaths minimize material scrap and cost. |

| Complex Geometries | Capable of producing intricate designs impossible by hand. |

| Heat & Deformation Control | Manages PTFE's thermal expansion and softness effectively. |

Need high-precision, custom CNC-machined PTFE components?

KINTEK specializes in manufacturing PTFE seals, liners, labware, and other critical components for the semiconductor, medical, laboratory, and industrial sectors. We leverage our expertise in precision CNC machining to overcome PTFE's unique challenges, delivering consistent, high-quality parts from prototypes to high-volume production runs.

Contact KINTEK today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability