In short, PTFE (Teflon) washers are exceptionally well-suited for electrical applications because they are one of the best electrical insulators known. Their unique molecular structure prevents the flow of electricity, resists moisture, and remains stable across a wide range of temperatures, ensuring both safety and reliable performance in critical components.

The core reason to choose PTFE for electrical applications is not just its ability to insulate, but its capacity to maintain that high level of insulation reliably under harsh conditions—including high voltage, humidity, and extreme temperatures—where other materials would fail.

The Core Electrical Properties of PTFE

To understand why PTFE is a premier choice, we must look at its specific electrical characteristics. These properties work in concert to provide a level of performance that is difficult to match.

Exceptional Electrical Insulation

PTFE has an extremely high electrical resistance, meaning it strongly opposes the flow of electrical current. This inherent quality is what makes it a superior insulator.

It is used to physically separate conductive surfaces, such as in electrical connectors or capacitors, effectively preventing short circuits and ensuring the integrity of the electrical system.

High Dielectric Strength

Dielectric strength measures a material's ability to withstand a strong electric field without breaking down and becoming conductive.

PTFE excels in this area, capable of insulating up to 500 volts per mil (one-thousandth of an inch) of thickness. This makes it ideal for high-voltage applications where insulation failure is not an option.

Low Dielectric Constant

Thanks to its highly symmetric molecular structure, PTFE has a very low dielectric constant (2.0) and a low dissipation factor.

In practical terms, this means it stores very little electrical energy and loses minimal energy as heat when exposed to an alternating electric field. This is critical for high-frequency components like data cables and semiconductors, where signal integrity is paramount.

Why PTFE Outperforms in Real-World Conditions

Beyond its fundamental electrical properties, PTFE's physical durability makes it a more robust choice than other common plastics like nylon or PVC in demanding electronic environments.

Superior Moisture Resistance

PTFE is fundamentally hydrophobic, meaning it repels water. It resists moisture penetration far better than most plastics.

This is a critical advantage because moisture absorption can severely degrade the insulating properties of other materials, leading to current leakage or failure over time. PTFE's performance remains consistent even in high-humidity environments.

Consistent Performance Across Temperatures

Electrical components can generate significant heat. PTFE maintains its excellent electrical and physical properties across a very wide range of operating temperatures.

This thermal stability ensures that the washer will not melt, deform, or lose its insulating capability when a device is under heavy load, making it a reliable choice for transformers and power electronics.

Chemical Inertness and Non-Flammability

PTFE is nearly universally inert to chemicals and is also non-flammable. This adds a crucial layer of safety, preventing the material from contributing to a fire in the event of an electrical fault.

Selecting PTFE for Your Electrical Application

Choosing the right material requires matching its properties to your primary goal. PTFE's versatility makes it suitable for a wide range of electrical design challenges.

- If your primary focus is high-voltage safety: Rely on PTFE's exceptional dielectric strength to prevent electrical breakdown in components like standoff insulators and transformers.

- If your primary focus is high-frequency signal integrity: Leverage PTFE's low dielectric constant for use in data cables, circuit boards, and semiconductors to minimize signal loss.

- If your primary focus is long-term reliability in harsh environments: Choose PTFE for its unmatched resistance to moisture, chemicals, and temperature fluctuations, ensuring stable performance for the life of the component.

Ultimately, specifying PTFE washers is a decision for robust, reliable, and safe electrical insulation.

Summary Table:

| Key Property | Benefit for Electrical Applications |

|---|---|

| High Dielectric Strength | Withstands high voltages (up to 500V/mil) without breakdown. |

| Low Dielectric Constant (2.0) | Minimizes signal loss, ideal for high-frequency components. |

| Excellent Moisture Resistance | Maintains insulating properties in humid environments. |

| Wide Temperature Stability | Performs reliably from extreme cold to high heat. |

| Chemical Inertness & Non-Flammability | Adds a crucial layer of safety and long-term reliability. |

Need reliable, high-performance PTFE components for your critical electrical applications?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom washers—for the semiconductor, medical, laboratory, and industrial sectors. We ensure your components meet the highest standards for electrical insulation, durability, and performance, from prototype to high-volume production.

Contact KINTEL today to discuss your project requirements and get a quote!

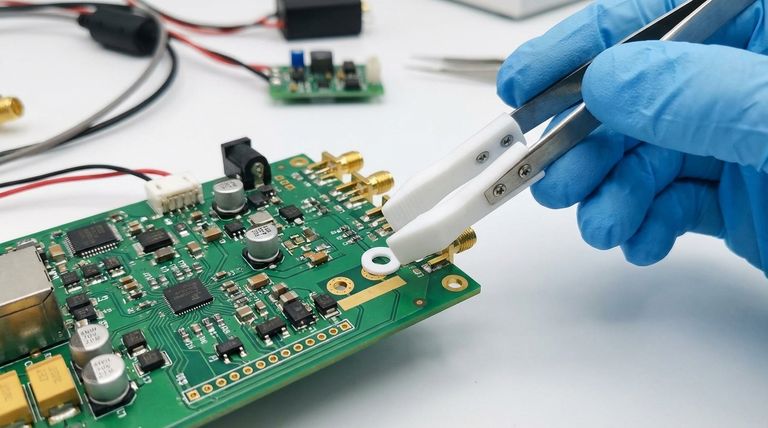

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech