In the high-stakes world of medical technology, Teflon, or Polytetrafluoroethylene (PTFE), is a cornerstone of reliability due to its unparalleled combination of properties. Its chemical and biological inertness prevents degradation from harsh sterilization chemicals or bodily fluids, while its extremely low friction ensures mechanical components operate smoothly and wear slowly, dramatically extending the equipment's functional lifespan.

The core reason Teflon is so vital for medical reliability is its ability to eliminate common points of failure. By resisting chemical attack, preventing adverse biological reactions, and minimizing mechanical wear, it ensures devices perform predictably and safely over their entire service life.

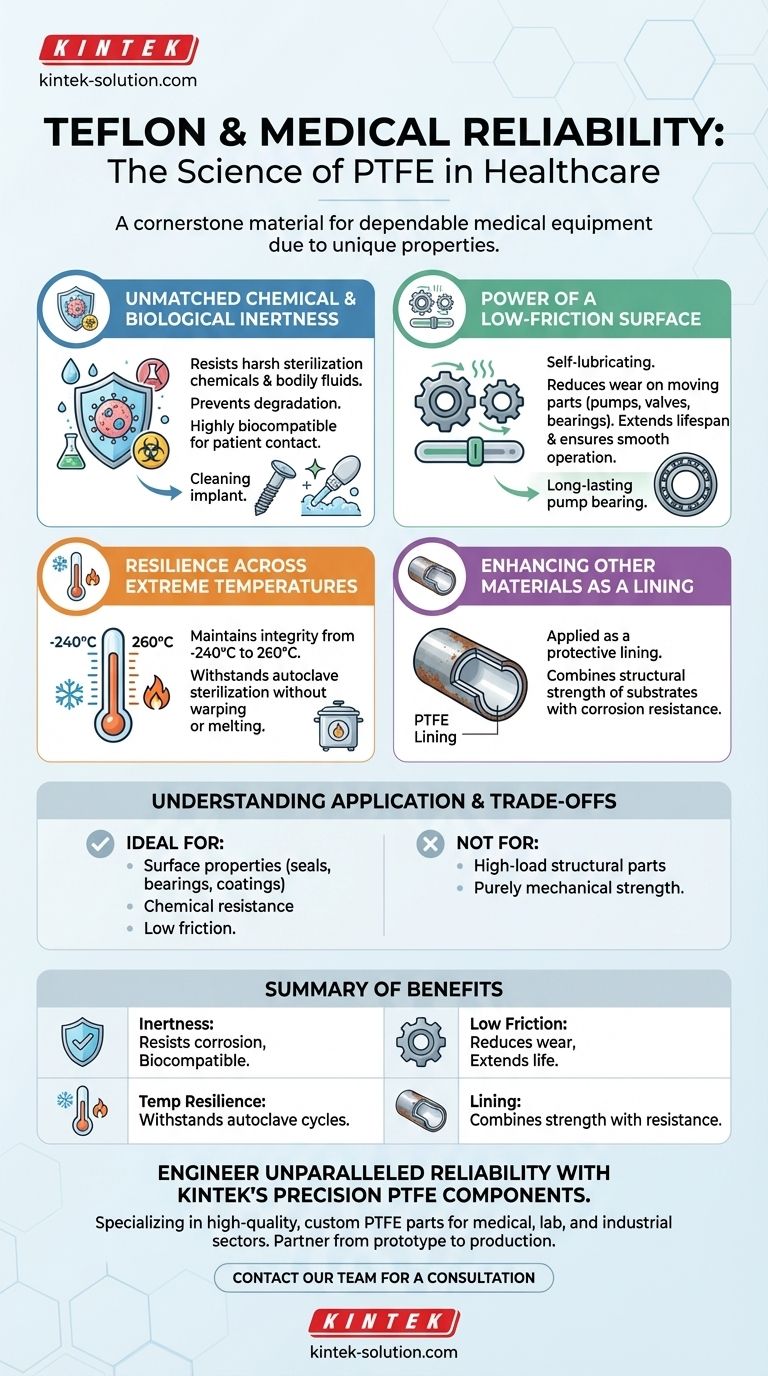

The Pillars of Teflon's Reliability

To understand Teflon's contribution, we must look at how its specific material properties solve critical challenges in medical device engineering. It isn't just one feature, but the combination of several, that makes it so effective.

Unmatched Chemical and Biological Inertness

Teflon is renowned for being almost completely inert. It does not react with the vast majority of chemicals, including aggressive acids, bases, and cleaning agents used in sterilization.

This property is critical for reliability. It means components like valve linings and seals won't corrode or degrade when exposed to harsh substances, preventing leaks and premature failure.

Furthermore, this inertness extends to biological environments. Teflon is highly biocompatible, meaning it won't react with bodily tissues or fluids, making it a safe and dependable choice for implants and tools that come into direct patient contact.

The Power of a Low-Friction Surface

Medical equipment often contains moving parts, such as pumps, valves, and bearings. Friction is the enemy of these components, causing wear, generating heat, and demanding more energy.

Teflon possesses one of the lowest coefficients of friction of any solid material, making it naturally self-lubricating. This dramatically reduces wear and tear on sealing and moving components.

The result is a longer operational lifespan, less required maintenance, and smoother, more efficient, and quieter operation—all of which are direct contributors to a device's overall reliability.

Resilience Across Extreme Temperatures

Medical devices must often endure extreme temperatures, most notably the high heat and steam of autoclave sterilization.

Teflon maintains its structural integrity and performance characteristics across an exceptionally wide temperature range, from as low as -400°F to over 500°F (-240°C to 260°C).

This thermal stability ensures that a component made with Teflon will not warp, melt, or degrade during essential sterilization cycles, guaranteeing it is ready and reliable for its next use.

Enhancing Other Materials as a Lining

Sometimes, a structural material like steel offers the necessary strength but lacks corrosion resistance. Teflon can be applied as a protective lining.

By lining the internal walls of components like valves, engineers can combine the strength of the base material with the chemical inertness of Teflon.

This approach overcomes the material deficiencies of both, creating a highly reliable and cost-effective hybrid component that resists corrosion without compromising on strength.

Understanding the Application Trade-offs

While Teflon's properties are exceptional, its reliability hinges on being used in the correct context. Understanding its limitations is just as important as knowing its strengths.

Structural Integrity Considerations

Teflon is a relatively soft material and does not possess high tensile strength or rigidity compared to metals or other engineering plastics.

It is therefore not suitable for high-load, purely structural applications. Its primary value is in its surface properties—as a bearing, seal, lining, or coating—where friction and chemical resistance are the dominant concerns.

The Importance of Proper Specification

The reliability benefits of Teflon are only realized when it is correctly specified for the application. Forcing it into a role it isn't suited for, such as a high-impact structural part, will lead to failure.

Expert material selection involves matching Teflon's unique profile (low friction, inertness) to the specific problem (wear, corrosion), often within a larger, more robust mechanical assembly.

How to Apply This to Your Project

When evaluating materials for a medical device, your primary goal will dictate how you leverage Teflon's properties.

- If your primary focus is patient safety and biocompatibility: Rely on Teflon for any component that contacts bodily fluids or tissues, such as catheters, grafts, or surgical instruments.

- If your primary focus is extending the life of mechanical systems: Use Teflon for bearings, seals, and gaskets in pumps and valves to minimize friction and prevent wear.

- If your primary focus is withstanding harsh sterilization: Specify Teflon for components that must endure repeated exposure to chemicals and high temperatures without degrading.

Ultimately, choosing the right material is a critical step in engineering dependable and safe medical equipment.

Summary Table:

| Property | Benefit for Medical Equipment |

|---|---|

| Chemical & Biological Inertness | Resists harsh sterilization chemicals and is biocompatible, preventing corrosion and adverse reactions. |

| Extremely Low Friction | Reduces wear on moving parts like seals and bearings, extending device lifespan and ensuring smooth operation. |

| Wide Temperature Resilience | Withstands extreme autoclave sterilization cycles (-240°C to 260°C) without warping or degrading. |

| Excellent as a Lining | Combines the strength of substrates like steel with superior corrosion resistance for hybrid components. |

Engineer unparalleled reliability into your medical devices with KINTEK's precision PTFE components.

As detailed in this article, the correct application of Teflon (PTFE) is critical for overcoming challenges like chemical corrosion, mechanical wear, and demanding sterilization cycles. At KINTEK, we specialize in manufacturing high-quality, custom PTFE components—including seals, liners, and labware—that are essential for the semiconductor, medical, laboratory, and industrial sectors.

We partner with you from prototype to high-volume production, ensuring every part meets the stringent requirements for safety, durability, and performance that your industry demands. Let's discuss how our expertise can enhance your next project. Contact our team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the safety features of PTFE-lined bottle caps? Ensure Chemical Inertness and Sample Integrity

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are the chemical compatibility properties of PTFE-lined bottle caps? Ensure Maximum Safety and Purity

- What application-specific considerations should be taken into account when selecting a PTFE-coated septum? Ensure Analytical Integrity

- What are the advantages of PTFE in pharmaceutical and biotech research? Ensure Purity and Prevent Contamination

- What are some specialized PTFE stirring bars available? Optimize Your Lab Mixing Efficiency

- How does the non-stick surface of PTFE shovels benefit laboratory work? Enhance Accuracy & Efficiency

- What types of samples are compatible with PTFE lined vials? Ensure Sample Integrity for Demanding Applications