Beyond the simple cylinder, a wide array of specialized PTFE stirring bars exists, each designed to solve specific mixing challenges in the laboratory. These designs include octagonal, egg-shaped, round, triangular, and cross-head bars, each offering unique hydrodynamic properties for different container shapes, liquid viscosities, and mixing speeds. The choice of stir bar is not arbitrary; it is a critical parameter for achieving efficient and consistent results.

The shape of a PTFE stir bar is a functional design choice, not an aesthetic one. Matching the bar's geometry to the vessel shape and the solution's properties is the key to creating the ideal vortex for efficient mixing, from gentle agitation to vigorous dissolution.

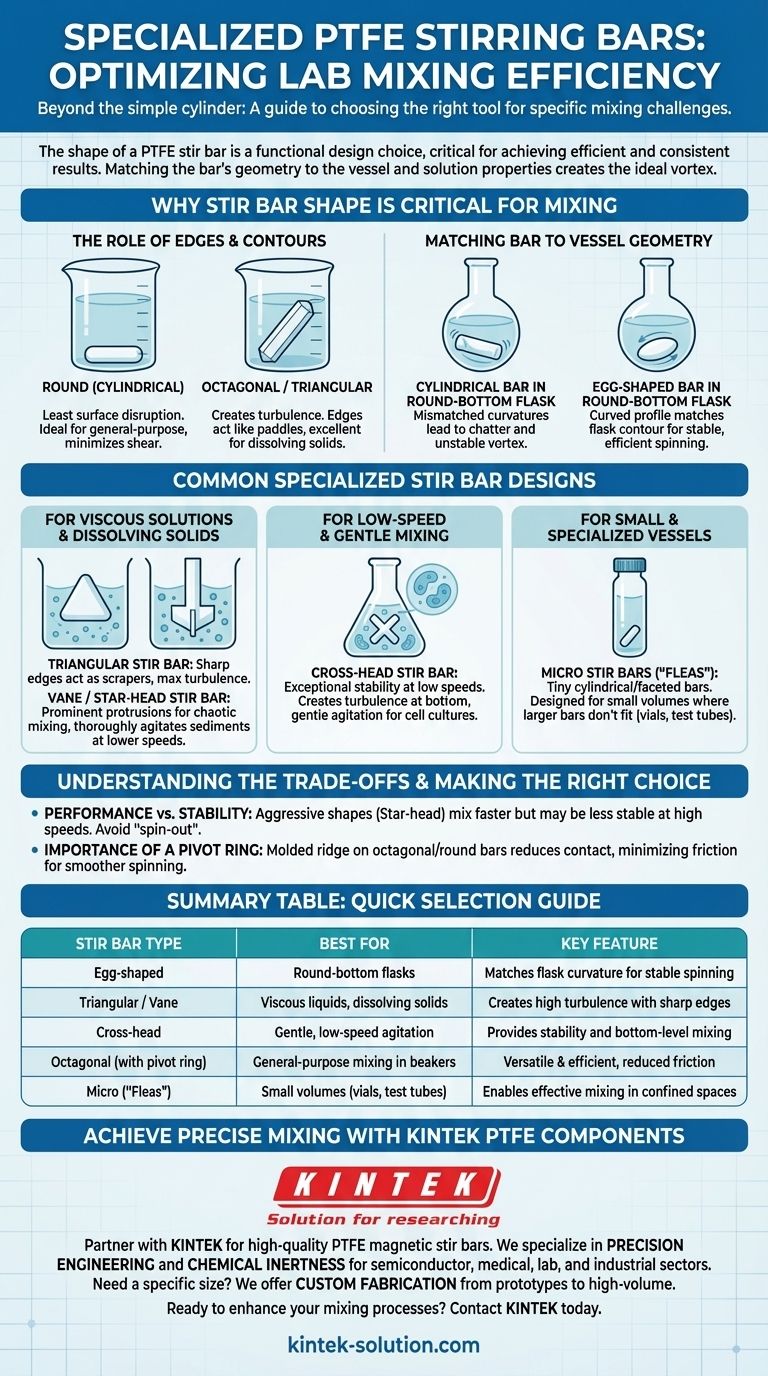

Why Stir Bar Shape is Critical for Mixing

The effectiveness of a magnetic stirrer depends entirely on the interaction between the spinning stir bar and the liquid. The shape of the bar dictates the nature of this interaction, influencing turbulence, vortex depth, and overall mixing efficiency.

The Role of Edges and Contours

A simple, smooth, round (or cylindrical) stir bar offers the least surface disruption. This makes it ideal for general-purpose agitation and for applications where minimizing shear force on the sample is important. It spins smoothly in flat-bottomed beakers.

In contrast, a bar with defined edges, like an octagonal or triangular stir bar, creates significantly more turbulence. These edges act like paddles, cutting through the liquid and generating a much stronger mixing vortex, which is crucial for dissolving solids quickly or blending immiscible liquids.

Matching Bar to Vessel Geometry

The shape of your container is a primary factor in stir bar selection. A standard cylindrical bar in a round-bottom flask will spin erratically, "chatter," and fail to create a stable vortex because of the mismatched curvatures.

This is precisely why the egg-shaped (or oval) stir bar was developed. Its curved profile perfectly matches the contour of a round-bottom flask, ensuring stable, wobble-free spinning and efficient mixing even at high speeds.

Common Specialized Stir Bar Designs

Each specialized design solves a specific problem. Understanding their intended function allows you to select the right tool for the job.

For Viscous Solutions and Dissolving Solids

Bars designed for high-turbulence applications excel at handling thicker liquids or breaking down stubborn solids.

The triangular stir bar acts like a scraper, with its sharp edges providing maximum surface contact and turbulence, making it excellent for preventing solids from settling at the bottom.

Similarly, vane or star-head stir bars feature prominent protrusions that create chaotic, highly effective mixing patterns. These are often used at lower speeds to thoroughly agitate sediments or mix viscous media without forming a deep vortex that could splash the contents.

For Low-Speed and Gentle Mixing

Sometimes, the goal is gentle agitation rather than creating a powerful vortex.

A cross-head magnetic stir bar provides exceptional stability at low speeds. It creates a high degree of turbulence right at the bottom of the vessel without necessarily pulling a deep vortex from the surface, making it ideal for gently agitating cell cultures or keeping solids in suspension.

For Small and Specialized Vessels

Standard stir bars are too large for vials, test tubes, or cuvettes.

Micro stir bars (often called "fleas") are tiny cylindrical or faceted bars designed specifically for these small-volume applications. Their small size allows for effective mixing in containers where a larger bar would not fit or be able to spin.

Understanding the Trade-offs

The primary material for these tools, Polytetrafluoroethylene (PTFE), is chosen for its extreme chemical inertness and low-friction surface. While the core is always a permanent magnet, the PTFE coating is non-negotiable for lab work.

Performance vs. Stability

A more aggressive shape like a star-head or triangular bar will mix faster and more thoroughly, but it may also be less stable at very high speeds compared to a simple octagonal or round bar. Choosing a bar that is too aggressive for your vessel can lead to "spin-out," where the bar loses its magnetic coupling and stops spinning.

The Importance of a Pivot Ring

Many octagonal and round stir bars feature a molded pivot ring around their center. This small ridge reduces the contact area with the vessel surface, minimizing friction and promoting smoother, more stable spinning, especially at higher RPMs. Bars without this feature have more surface contact, which can be beneficial for agitating solids at the bottom but may lead to more operational noise and friction.

Making the Right Choice for Your Application

Selecting the correct stir bar is a simple way to optimize your experimental setup for success.

- If your primary focus is mixing in a round-bottom flask: Use an egg-shaped stir bar to match the vessel's curvature for maximum stability.

- If your primary focus is dissolving solids or mixing viscous liquids: Choose a triangular, vane, or star-head bar to create high turbulence.

- If your primary focus is general-purpose mixing in a flat-bottom beaker: An octagonal bar with a pivot ring is the most versatile and efficient choice.

- If your primary focus is gentle, low-speed agitation: A cross-head stir bar provides excellent stability and bottom-level mixing.

- If your primary focus is working with vials or test tubes: Use a micro stir bar appropriately sized for the small volume.

Ultimately, viewing your stir bar as a piece of precision equipment, not just a commodity, will lead to more consistent and repeatable results.

Summary Table:

| Stir Bar Type | Best For | Key Feature |

|---|---|---|

| Egg-shaped | Round-bottom flasks | Matches flask curvature for stable spinning |

| Triangular / Vane | Viscous liquids, dissolving solids | Creates high turbulence with sharp edges |

| Cross-head | Gentle, low-speed agitation (e.g., cell cultures) | Provides stability and bottom-level mixing |

| Octagonal (with pivot ring) | General-purpose mixing in beakers | Versatile and efficient with reduced friction |

| Micro ('Fleas') | Small volumes (vials, test tubes) | Enables effective mixing in confined spaces |

Achieve Precise and Consistent Mixing with KINTEK PTFE Components

Just as selecting the right stir bar shape is critical for your lab results, partnering with the right manufacturer is key to ensuring reliability and performance. At KINTEK, we specialize in the precision production of high-quality PTFE components, including a full range of specialized magnetic stir bars.

We understand the demanding environments of the semiconductor, medical, laboratory, and industrial sectors. That’s why we prioritize:

- Chemical Inertness: Our PTFE components are compatible with a vast range of aggressive chemicals.

- Precision Engineering: From standard octagonal bars to custom egg-shaped designs for round-bottom flasks, every detail is crafted for optimal performance.

- Custom Fabrication: Need a specific size or design? We offer custom solutions from prototypes to high-volume orders.

Ready to enhance your mixing processes with components built for precision? Contact KINTEK today to discuss your specific needs and let our expertise work for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech