In pharmaceutical and biotech research, the primary advantages of Polytetrafluoroethylene (PTFE) are its extreme chemical inertness, high purity, and low surface adhesion. These properties are critical for preventing sample contamination, ensuring the integrity of analytical results, and maintaining compliance with strict regulatory standards.

The core value of PTFE in a lab or production setting is its ability to be a non-participant. It acts as an invisible, protective barrier, ensuring that the container, seal, or valve does not react with, absorb, or contaminate the sensitive and valuable materials it holds.

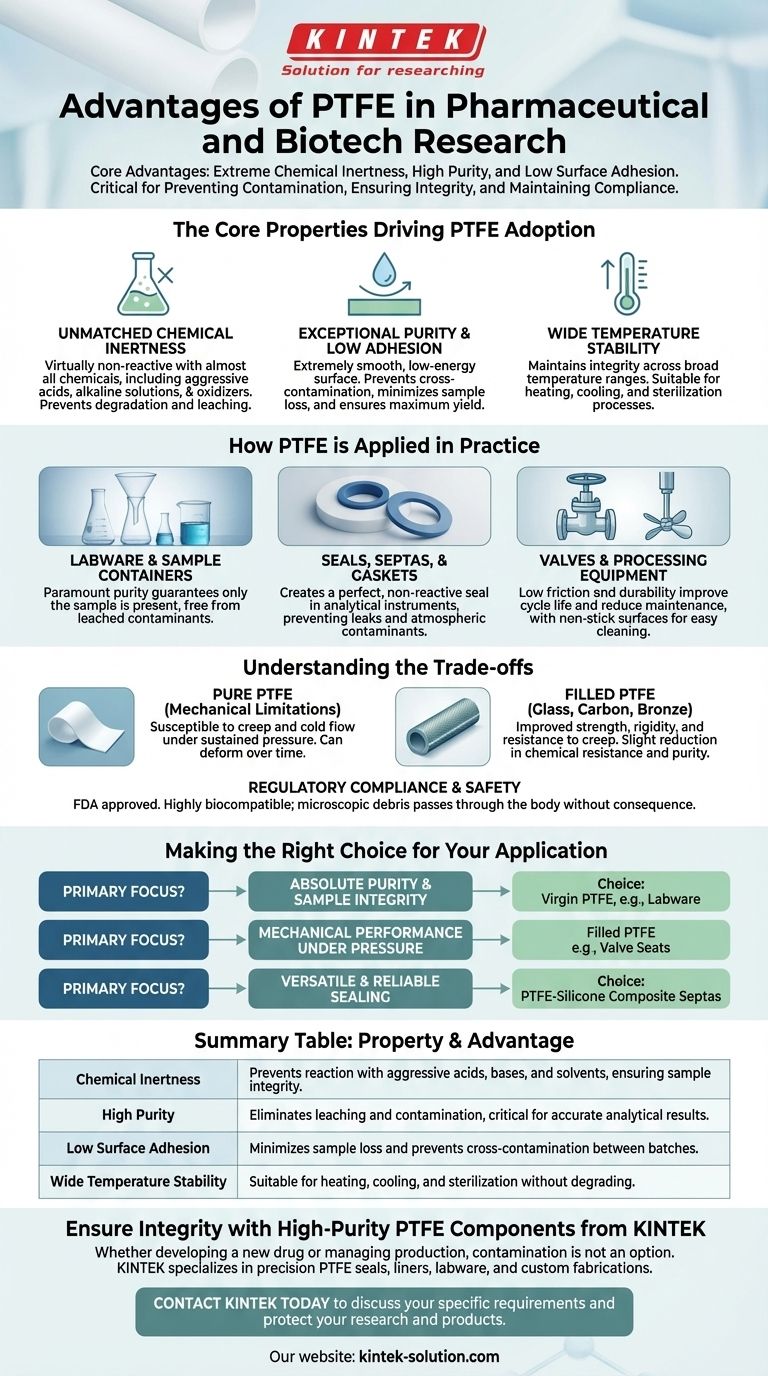

The Core Properties Driving PTFE Adoption

The unique molecular structure of PTFE, known commercially as Teflon, gives it a combination of properties that are almost perfectly suited for the demanding environments of pharmaceutical and biotech work.

Unmatched Chemical Inertness

PTFE is virtually non-reactive with almost all chemicals, including aggressive acids, alkaline solutions, and strong oxidizers. This inertness is fundamental, as it prevents the material from degrading or leaching unwanted substances into a drug formulation or a sensitive biological sample.

This property ensures that the results of an analysis or the composition of a product are due to the intended ingredients, not an unwanted chemical reaction with the equipment.

Exceptional Purity and Low Adhesion

The surface of PTFE is extremely smooth and has very low energy, making it difficult for other materials to stick to it. This "non-stick" quality is vital for preventing cross-contamination between batches.

It also minimizes the loss of valuable products that might otherwise adhere to the surfaces of containers, valves, or tubing, ensuring maximum yield and accurate measurements.

Wide Temperature Stability

PTFE maintains its integrity across a broad range of temperatures. This allows it to be used in processes that involve heating, cooling, and sterilization without compromising its structural or chemical properties.

This versatility simplifies equipment selection, as a single material can be trusted for multiple stages of research, development, and production.

How PTFE is Applied in Practice

These fundamental properties translate directly into tangible benefits across various types of equipment used in labs and manufacturing facilities.

Labware and Sample Containers

For items like funnels, beakers, and storage containers, PTFE's purity is paramount. It guarantees that the only thing in the container is the sample itself, free from leached contaminants that could skew test results.

Seals, Septas, and Gaskets

In analytical instruments and reactors, PTFE and PTFE-silicone septas create a perfect, non-reactive seal. This prevents leaks and stops atmospheric contaminants from entering, preserving the integrity of the process and ensuring the safety of personnel.

Valves and Processing Equipment

PTFE diaphragm valves and linings for equipment like mixers and presses benefit from the material's low friction and durability. The material's high cycle life reduces maintenance, while its non-stick surface ensures smooth flow and easy cleaning between batches.

Understanding the Trade-offs

While its properties are exceptional, it's important to understand the limitations of pure PTFE to select the right material for a specific mechanical application.

Mechanical Limitations of Pure PTFE

In its pure form, PTFE can be susceptible to creep and cold flow, meaning it can slowly deform under sustained pressure or load. This can be a concern in high-pressure sealing applications where maintaining a constant shape is critical.

The Role of "Filled" PTFE

To counteract these mechanical weaknesses, PTFE is often compounded with fillers like glass, carbon, or bronze. These "filled PTFE" variants offer significantly improved strength, rigidity, and resistance to creep.

The trade-off is that these fillers can slightly reduce the chemical resistance and purity of the material, requiring careful selection based on the specific chemicals and pressures involved.

Regulatory Compliance and Safety

PTFE is approved by the FDA for use in pharmaceutical applications. Its biocompatibility is so high that should any microscopic debris from a seal or bushing enter the product stream, it is known to pass through the body without consequence, adding a significant layer of safety.

Making the Right Choice for Your Application

Selecting the correct grade of PTFE requires matching the material's properties to the primary goal of your process.

- If your primary focus is absolute purity and sample integrity: Pure, virgin PTFE is the unmatched choice for labware and low-pressure applications where non-reactivity is the highest priority.

- If your primary focus is mechanical performance under pressure: A filled PTFE, such as glass-filled or carbon-filled, is necessary for high-load applications like valve seats or dynamic seals.

- If your primary focus is versatile and reliable sealing: PTFE-silicone composite septas offer an excellent balance of chemical inertness on the contact surface with the resealability and flexibility of silicone.

Ultimately, choosing PTFE is a decision to prioritize reliability, purity, and safety in your critical processes.

Summary Table:

| Property | Advantage in Pharma/Biotech |

|---|---|

| Chemical Inertness | Prevents reaction with aggressive acids, bases, and solvents, ensuring sample integrity. |

| High Purity | Eliminates leaching and contamination, critical for accurate analytical results and compliance. |

| Low Surface Adhesion | Minimizes sample loss and prevents cross-contamination between batches. |

| Wide Temperature Stability | Suitable for heating, cooling, and sterilization processes without degrading. |

Ensure the integrity of your most critical samples and processes with high-purity PTFE components from KINTEK.

Whether you are developing a new drug, conducting sensitive bio-analytical tests, or managing production, contamination is not an option. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom fabrications—specifically for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors.

We help you select the right PTFE grade (pure or filled) for your application, balancing absolute purity with the necessary mechanical strength. From prototypes to high-volume orders, our commitment to precision production guarantees reliability and compliance.

Contact KINTEK today to discuss your specific requirements and discover how our PTFE solutions can protect your research and products.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are the primary applications of PTFE? Unlocking High-Performance Solutions