To select the right PTFE-coated septum, you must move beyond the component itself and evaluate your specific application's chemical, physical, and analytical demands. The ideal choice balances chemical inertness against mechanical resilience and is manufactured with a robust bonding process to prevent failure. This ensures sample integrity for sensitive analyses and reliable performance in demanding physical conditions.

The most common mistake is viewing a septum as a simple seal. It is an active component in your system where the wrong choice can introduce contamination, cause sample loss, or lead to mechanical failure. The key is to match the septum's material properties and manufacturing quality to your specific analytical and operational risks.

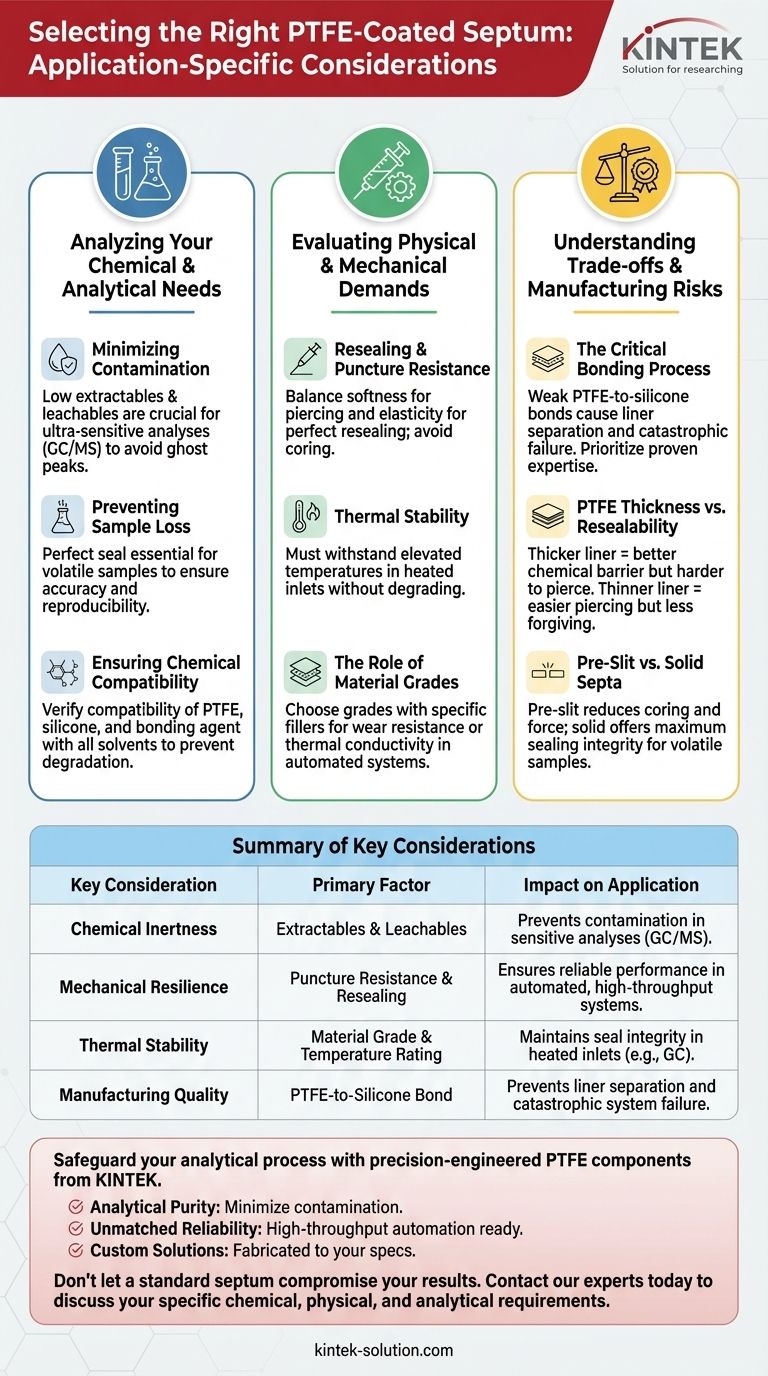

Analyzing Your Chemical and Analytical Needs

The primary purpose of a PTFE coating is to provide a chemically inert barrier. However, the degree of inertness required and the prevention of sample loss are dictated entirely by your application.

Minimizing Contamination

For ultra-sensitive analyses like gas chromatography (GC) or mass spectrometry, the primary concern is contamination. You must select septa with minimal extractables and leachables. These are chemical compounds that can migrate from the septum material into your sample, appearing as ghost peaks or interfering with your results.

Preventing Sample Loss

In applications involving volatile samples, such as GC, the septum's ability to create and maintain a perfect seal is paramount. A poor seal leads to sample loss through evaporation, compromising the accuracy and reproducibility of your analysis. The septum's material composition and design directly impact its resealing capability after being punctured.

Ensuring Chemical Compatibility

While PTFE is exceptionally inert, the underlying material (typically silicone) and the bonding agent are not. It is critical to verify that all components of the septum are compatible with your specific samples and solvents, especially when dealing with aggressive chemicals that could degrade the silicone if the PTFE liner fails.

Evaluating Physical and Mechanical Demands

A septum must withstand the physical stresses of its environment and use. This includes repeated punctures, high temperatures, and the mechanical forces of an autosampler.

Resealing and Puncture Resistance

The septum's core mechanical function is to allow a needle to pass through and then reseal perfectly upon withdrawal. This requires a balance of softness for easy piercing and elasticity for resealing. Poor mechanical strength can lead to coring, where small particles of the septum are carved out by the needle and deposited into your sample or instrument.

Thermal Stability

For applications like a heated GC inlet, the septum must maintain its integrity and sealing properties at elevated temperatures. Manufacturers offer different grades of materials designed for specific temperature ranges. Exceeding a septum's thermal limit can cause it to degrade, leading to leaks and system contamination.

The Role of Material Grades

Not all PTFE is the same. Manufacturers offer various grades, often using fillers to enhance specific properties like wear resistance or thermal conductivity. Understanding these different formulations allows you to choose a septum tailored to the unique mechanical stresses of your application, such as high-throughput automated systems.

Understanding the Trade-offs and Manufacturing Risks

Selecting a septum involves balancing competing properties and, crucially, trusting the quality of its construction. A poorly made septum is a significant point of failure.

The Critical Nature of the Bonding Process

The bond between the PTFE liner and the silicone base is a frequent failure point. An improper or weak bond can cause the liner to separate, exposing your sample to the less-inert silicone, causing rapid degradation of the seal, and potentially leading to catastrophic system failure. Always prioritize manufacturers with proven expertise in this bonding process.

PTFE Thickness vs. Resealability

A common trade-off exists between chemical protection and physical performance. A thicker PTFE liner offers a more robust chemical barrier but can be harder to pierce and may compromise the septum's ability to reseal effectively. A thinner layer is easier on the needle but provides a less forgiving barrier.

Pre-Slit vs. Solid Septa

Many septa are available with a pre-cut slit to guide the needle. This design significantly reduces the force needed for penetration and minimizes the risk of coring, especially with blunter needles. However, for highly volatile samples or applications requiring maximum sealing integrity, a solid, non-slit septum may provide a more reliable seal.

Making the Right Choice for Your Application

Your final decision should be guided by your primary objective. By clarifying your main priority, you can select a septum that is optimized for your specific goal.

- If your primary focus is ultra-sensitive trace analysis: Prioritize septa certified for low bleed and minimal extractables to ensure analytical purity.

- If your primary focus is high-throughput automation: Select septa specifically engineered for high puncture tolerance and reliable resealing to prevent failed injections and instrument downtime.

- If your primary focus is working with aggressive solvents: Verify the chemical compatibility of all septum materials and ensure you are using a product with a robust, high-quality PTFE-to-silicone bond.

Ultimately, selecting the right septum is a critical step in safeguarding the integrity of your entire analytical process.

Summary Table:

| Key Consideration | Primary Factor | Impact on Application |

|---|---|---|

| Chemical Inertness | Extractables & Leachables | Prevents contamination in sensitive analyses (GC/MS). |

| Mechanical Resilience | Puncture Resistance & Resealing | Ensures reliable performance in automated, high-throughput systems. |

| Thermal Stability | Material Grade & Temperature Rating | Maintains seal integrity in heated inlets (e.g., GC). |

| Manufacturing Quality | PTFE-to-Silicone Bond | Prevents liner separation and catastrophic system failure. |

Safeguard your analytical process with precision-engineered PTFE components from KINTEK.

Your application's success depends on the integrity of every component. KINTEK specializes in manufacturing high-performance PTFE septa, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We prioritize the critical bonding process and material selection to deliver components that ensure:

- Analytical Purity: Minimize extractables for contamination-free trace analysis.

- Unmatched Reliability: Withstand the demands of high-throughput automation and repeated punctures.

- Custom Solutions: From prototypes to high-volume orders, we fabricate to your exact specifications.

Don't let a standard septum compromise your results. Contact our experts today to discuss your specific chemical, physical, and analytical requirements.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the main advantages of PTFE as a material for laboratory bottles? Superior Chemical & Thermal Resistance

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What overall role do PTFE/silicone septa play in HPLC workflows? Protect Sample Integrity for Accurate Results

- What are common industrial applications of PTFE filters? Master Critical Filtration in Demanding Industries

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What are the key properties of Teflon membranes? Ensure Chemical Resistance and Sample Purity

- What is the correct placement of the PTFE washer in a stopcock plug assembly? Ensure Smooth, Leak-Free Operation

- What additional advantages does PTFE offer for laboratory use? Maximize Purity and Reliability