In the chemical processing industry, Teflon is indispensable for its trifecta of properties: near-total chemical inertness, high-temperature stability, and an extremely low coefficient of friction. These characteristics allow it to protect critical equipment, ensure process purity, and maintain operational safety in environments where most other materials would rapidly fail.

The core benefit of Teflon is not just its material properties, but its function as a risk mitigation tool. It acts as a crucial barrier, preventing costly equipment corrosion, hazardous leaks, and product contamination in the most aggressive chemical environments.

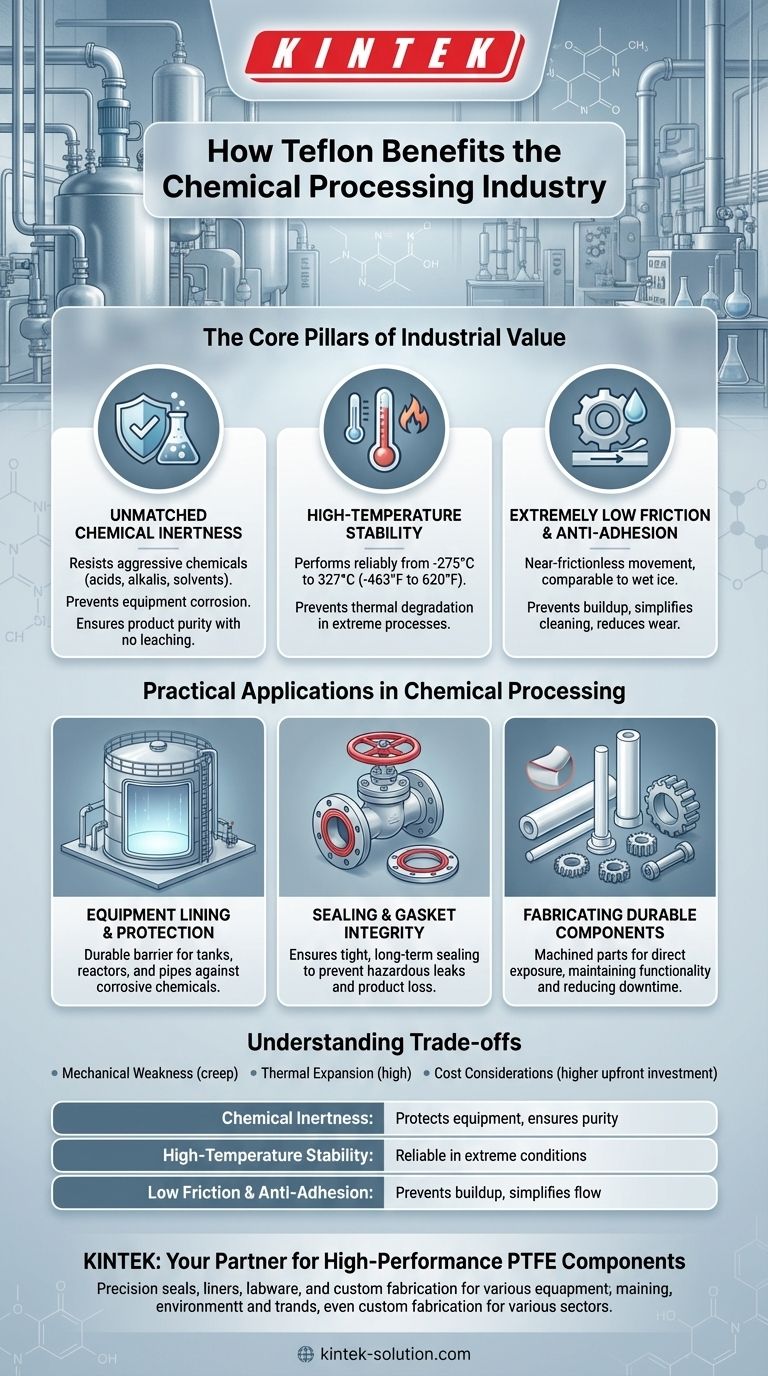

The Core Pillars of Teflon's Industrial Value

To understand why Teflon (PTFE) is a cornerstone material in chemical processing, we must look beyond a simple features list and examine the functional advantages these properties provide in a high-stakes industrial setting.

Unmatched Chemical Inertness

Teflon is famously resistant to a vast range of aggressive chemicals, including strong acids, alkalis, and potent organic solvents.

This inertness is critical because it prevents two major problems. First, it stops the chemical from corroding and destroying the equipment. Second, it ensures the Teflon itself does not react with, leach into, or contaminate the chemical product, preserving its purity.

High-Temperature Stability

Chemical processes often involve extreme temperatures, both high and low. Teflon maintains its structural and chemical integrity across an exceptionally wide thermal range.

It can perform reliably in applications up to 327°C (620°F) and remains functional in cryogenic conditions as low as -275°C (-463°F). This versatility allows it to be specified for a wide array of processes without concern for thermal degradation.

Extremely Low Friction and Anti-Adhesion

Teflon possesses one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This is complemented by its well-known non-stick, or anti-adhesion, properties.

In a chemical plant, this means components like valve seats and seals operate smoothly without sticking or seizing. Furthermore, it prevents materials from building up on surfaces, which simplifies cleaning and maintenance and ensures consistent flow.

Practical Applications in Chemical Processing

These core properties translate directly into tangible solutions that solve daily challenges for chemical engineers and plant operators.

Equipment Lining and Protection

One of the most common uses for Teflon is as a protective liner. Large sheets are fabricated to line storage tanks, reaction vessels, and long stretches of pipe.

This creates a durable, non-reactive barrier between the corrosive chemical and the structural metal (like carbon steel) of the equipment. It is a highly effective strategy for extending the life of capital-intensive assets.

Sealing and Gasket Integrity

Preventing leaks is a paramount concern for both safety and environmental compliance. Teflon is fabricated into gaskets, O-rings, valve seats, and gland fillers.

Its ability to create a tight seal, resist chemical attack, and handle high temperatures ensures long-term, reliable performance. This prevents the release of hazardous materials and the loss of valuable products.

Fabricating Durable Components

Beyond linings and seals, solid Teflon rods and blocks are machined to create custom components that are directly exposed to harsh process fluids.

These parts—from pump components to insulators—maintain their shape and functionality even after prolonged exposure. Their durability and wear resistance contribute directly to longer maintenance intervals and reduced downtime.

Understanding the Trade-offs

While its benefits are significant, Teflon is not a universal solution. An objective assessment requires acknowledging its limitations.

Mechanical Weakness

Compared to metals and even other engineering plastics, Teflon is a relatively soft material. It can be susceptible to "creep" or "cold flow," where the material slowly deforms under sustained mechanical pressure. This must be a key consideration in high-load structural designs.

Thermal Expansion

Teflon has a relatively high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. This must be accounted for in the design of parts that require tight tolerances, especially when mated with metal components.

Cost Considerations

Teflon is a premium material with a higher upfront cost than many alternatives. The decision to use it is an investment, trading higher initial expense for significantly lower long-term costs related to maintenance, equipment replacement, and operational downtime.

Making the Right Choice for Your Application

Selecting Teflon is a strategic decision based on the specific demands of the process environment.

- If your primary focus is asset protection and uptime: Use Teflon for linings in tanks and pipes to create a robust barrier against corrosion from aggressive chemicals.

- If your primary focus is process safety and leak prevention: Specify Teflon for gaskets, seals, and valve seats where chemical compatibility and reliable long-term sealing are non-negotiable.

- If your primary focus is maintaining product purity: Choose Teflon for any component that directly contacts high-purity chemicals, as its inertness ensures no leaching or contamination will occur.

Ultimately, integrating Teflon is a proven engineering decision to enhance safety, reliability, and efficiency in demanding chemical environments.

Summary Table:

| Key Property | Industrial Benefit |

|---|---|

| Chemical Inertness | Resists corrosion, prevents product contamination, and protects equipment from acids, alkalis, and solvents. |

| High-Temperature Stability | Maintains integrity from -275°C to 327°C, ensuring reliable performance in extreme process conditions. |

| Low Friction & Anti-Adhesion | Prevents material buildup, reduces wear on seals and valves, and simplifies cleaning for consistent flow. |

Need a reliable partner for high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact solution to protect your equipment, guarantee process purity, and maximize uptime.

Let's discuss how our PTFE solutions can solve your specific chemical processing challenges. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How is a PTFE bearing pad installed on prefabricated beams? A Guide to Secure, Low-Friction Installation

- What are the temperature ranges for PTFE and graphite packing? A Guide to Selecting the Right Seal

- What additional devices can be equipped with the PTFE seat butterfly valve? Enhance Valve Performance with Automation

- How is the coefficient of friction for PTFE measured? A Guide to Precise Friction Data

- What are the advantages of PTFE rotary shaft lip seals? Superior Performance in Extreme Conditions

- What are the general functions of bellows in mechanical systems? Achieve Superior System Reliability

- How does the low friction coefficient of PTFE expansion bellows benefit fluid flow? Reduce Energy Use & Prevent Blockages

- What was required for the successful development of PTFE-based bearings? Master the Critical Partnership for High-Performance Bearings