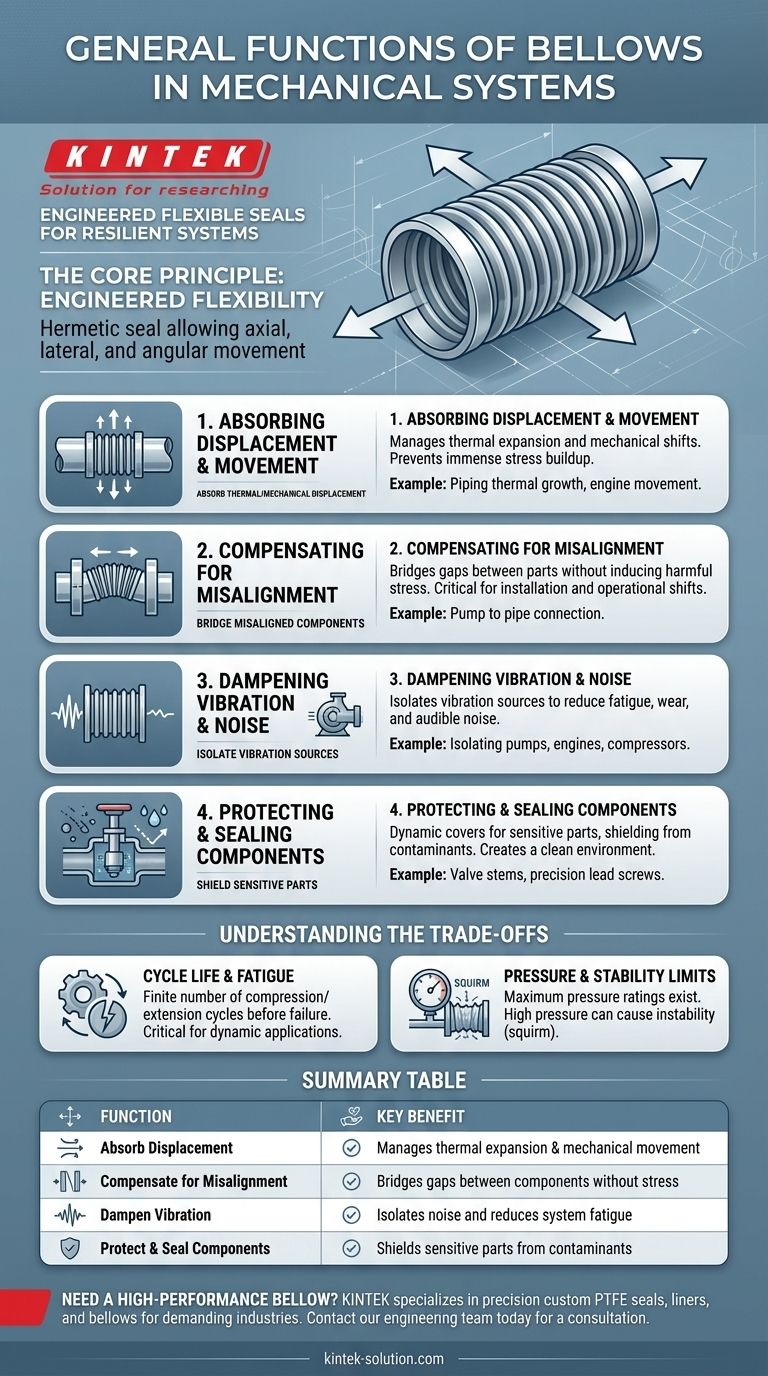

At their core, mechanical bellows are engineered flexible seals designed to perform four primary functions in a system. They absorb thermal or mechanical displacement, compensate for component misalignment, dampen vibration, and act as a protective barrier for sensitive components.

The fundamental purpose of a bellow is to provide a flexible connection between two points. This flexibility allows it to absorb unwanted movement, pressure, or vibration, preventing that energy from damaging other parts of the system.

The Core Principle: Engineered Flexibility

A mechanical bellow is a series of convolutions, or folds, that allow it to expand and contract along its axis much like an accordion. This simple principle is what makes it so versatile.

This design creates a hermetic seal that remains intact even as the bellow compresses, extends, or bends. It provides movement while preventing leaks.

Function 1: Absorbing Displacement and Movement

In many systems, components move. Bellows are designed to safely absorb this movement.

The most common example is thermal expansion in piping. As fluids heat up, the pipe expands. A bellow installed in the line will compress to absorb this growth, preventing immense stress from building up and causing a rupture.

They also handle mechanical movement, such as the shifting of an engine on its mounts or the settlement of a building's foundation affecting internal pipework.

Function 2: Compensating for Misalignment

Achieving perfect alignment between two connecting parts, like a pump and a pipe, is often difficult and expensive.

A bellow acts as a flexible joint, bridging the gap between two slightly misaligned components. It bends to connect them without inducing harmful stress on either end.

This function is critical during initial installation and also accommodates gradual shifting that may occur over the system's operational life.

Function 3: Dampening Vibration and Noise

Pumps, engines, and compressors are major sources of vibration and noise that can travel through a mechanical system.

A bellow, acting as a flexible connector, isolates the vibration source from the rest of the system. Its flexible structure absorbs the vibrational energy, stopping it from propagating down a pipe or into a support structure.

This not only reduces system fatigue and wear but also significantly lowers audible noise.

Function 4: Protecting and Sealing Components

Bellows can be used as dynamic protective covers for sensitive mechanical parts.

For example, a bellow can seal the stem of a valve or a precision lead screw. It allows the component to move freely while completely shielding it from dust, moisture, chemicals, and other external contaminants that would cause damage.

In this role, the bellow essentially creates a self-contained, clean environment for the component to operate within.

Understanding the Trade-offs

While incredibly useful, bellows are not a universal solution. Their flexibility comes with inherent limitations that must be respected in any design.

Cycle Life and Material Fatigue

Every compression and extension is a "cycle." Bellows are rated for a finite number of cycles before the material fatigues and fails. This is a critical factor in dynamic applications with constant movement.

Material choice (such as stainless steel, Inconel, or bronze) is determined by the required cycle life, operating temperature, and corrosive environment.

Pressure and Stability Limits

Internal pressure creates a force that tries to extend the bellow. If the pressure is too high, it can cause a long, slender bellow to become unstable and buckle sideways, an event known as squirm.

Every bellow has a maximum pressure rating that cannot be exceeded. In high-pressure applications, external reinforcement or specialized bellow designs are often required.

Making the Right Choice for Your Goal

Selecting the correct bellow depends entirely on the problem you are trying to solve.

- If your primary focus is managing pipe expansion: You need an expansion joint, a type of bellow specifically designed to handle axial movement and resist system pressure.

- If your primary focus is isolating a vibrating engine: You need a flexible connector optimized for vibration dampening, often with a specific convolution shape and material to absorb key frequencies.

- If your primary focus is protecting a valve stem from debris: You need a protective bellow where durability and resistance to the external environment are the most important factors.

By understanding these core functions, you can leverage the unique flexibility of bellows to build more resilient, reliable, and long-lasting mechanical systems.

Summary Table:

| Function | Key Benefit |

|---|---|

| Absorb Displacement | Manages thermal expansion & mechanical movement |

| Compensate for Misalignment | Bridges gaps between components without stress |

| Dampen Vibration | Isolates noise and reduces system fatigue |

| Protect & Seal Components | Shields sensitive parts from contaminants |

Need a high-performance bellow for your critical application?

KINTEK specializes in the precision manufacturing of custom PTFE seals, liners, and bellows for demanding industries like semiconductor, medical, and laboratory. Our expertise ensures your components withstand challenging environments, from extreme temperatures to corrosive chemicals.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing a perfect fit and superior performance for your system's unique requirements.

Contact our engineering team today for a consultation on your specific bellow needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the material options for PTFE O-ring seals? A Guide to High-Performance Filled PTFE Compounds

- What advantages do Teflon sheets have over metal sheets? Discover Unmatched Chemical & Non-Stick Properties

- What is PTFE packing and what are its primary characteristics? Master Sealing for Extreme Conditions

- Are expanded PTFE gaskets as durable as standard PTFE gaskets? Discover the Best Choice for Your Seal.

- How does PTFE's thermal expansion and contraction affect its machining and application? Master Dimensional Stability

- What are the main components of a Teflon lip seal? A Guide to Reliable PTFE Sealing

- How does PTFE's low thermal conductivity impact machining? Master Heat Management for Precision Parts

- Why might PTFE gaskets fail in sanitary applications? The Hidden Mechanical Flaws in a Chemically Perfect Material