The primary advantages of PTFE rotary shaft lip seals are their superior performance in demanding conditions where traditional rubber seals fail. They are defined by their exceptionally low friction, wide operating temperature range, near-universal chemical resistance, and ability to handle high speeds and pressures, often without lubrication.

The core decision to use a PTFE seal is not just about finding a better seal, but about solving a more difficult engineering problem. PTFE excels in applications involving extreme temperatures, aggressive chemicals, or high rotational speeds that would cause conventional elastomer seals to degrade and fail prematurely.

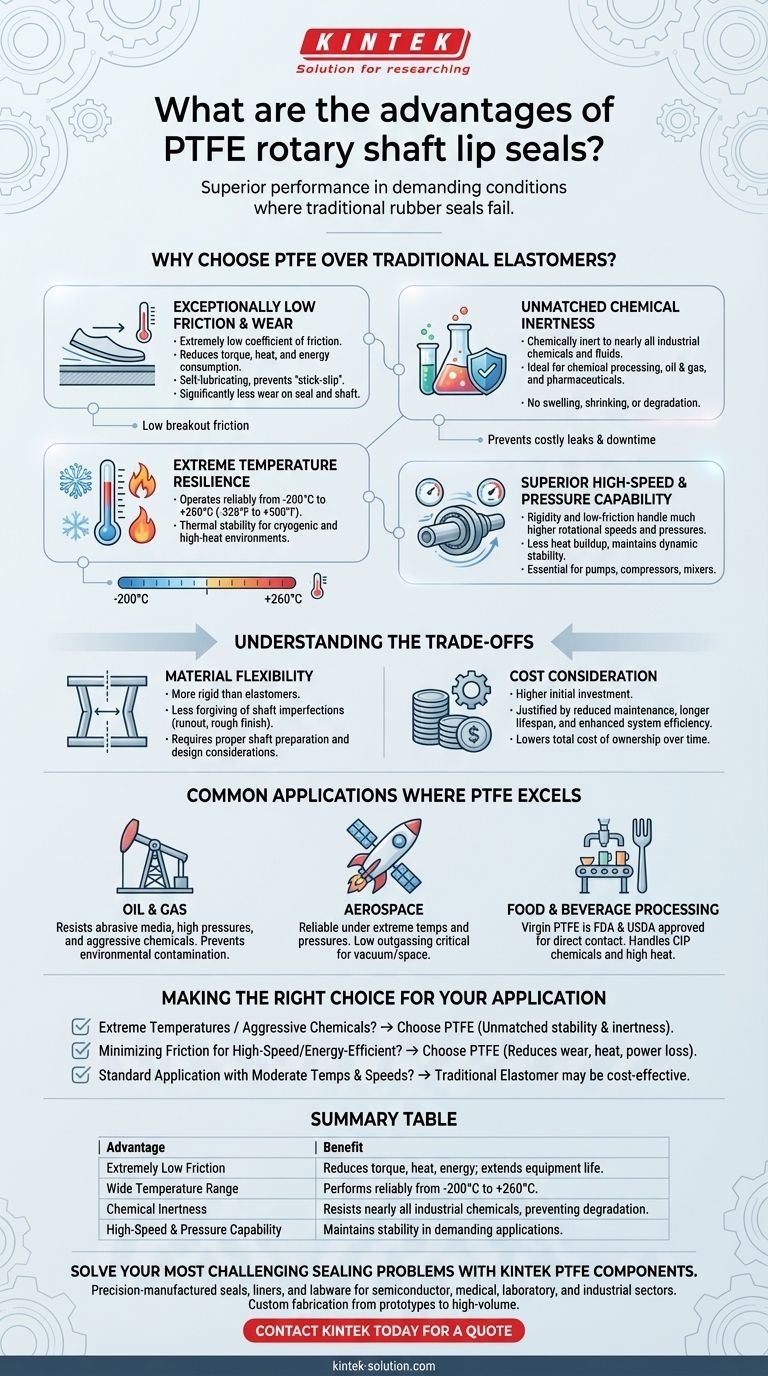

Why Choose PTFE Over Traditional Elastomers?

While standard rubber (elastomer) seals are effective in many general applications, they have clear operational limits. PTFE (polytetrafluoroethylene) seals are specifically engineered to overcome these limitations, providing reliability in the most challenging environments.

Exceptionally Low Friction and Wear

PTFE has an extremely low coefficient of friction, allowing it to glide over shafts with minimal resistance. This reduces torque, heat generation, and energy consumption.

This self-lubricating property also prevents the "stick-slip" behavior common in elastomers, ensuring smooth operation from a standstill (low breakout friction). The result is significantly less wear on both the seal and the shaft, extending the service life of your equipment.

Unmatched Chemical Inertness

PTFE is chemically inert to nearly all industrial chemicals and fluids. This makes it the ideal choice for applications in sectors like chemical processing, oil and gas, and pharmaceuticals.

Unlike elastomers that can swell, shrink, or degrade when exposed to aggressive media, PTFE maintains its integrity and sealing capability, preventing costly leaks and downtime.

Extreme Temperature Resilience

PTFE seals operate reliably across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This thermal stability allows them to perform in cryogenic applications as well as high-heat environments found in engines, gearboxes, and industrial machinery where rubber seals would become brittle or melt.

Superior High-Speed and Pressure Capability

The rigidity and low-friction nature of PTFE allow these seals to handle much higher rotational speeds and pressures than their elastomer counterparts. They are less prone to heat buildup and dynamic instability at speed.

This makes them essential for high-performance applications such as pumps, compressors, and mixers where operational demands exceed the physical limits of rubber.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE offers elite performance, it's important to understand its inherent characteristics.

Material Flexibility

PTFE is a more rigid material than traditional elastomers. This means it is less forgiving of shaft imperfections, such as significant runout or rough surface finishes.

Proper shaft preparation is critical to ensure an effective and long-lasting seal. The lack of elasticity also requires different design considerations for installation compared to a flexible rubber seal.

Cost Consideration

High-performance materials command a higher initial investment. PTFE seals are typically more expensive than standard nitrile or viton seals.

However, this cost is often justified by reduced maintenance, longer equipment lifespan, and enhanced system efficiency, which lowers the total cost of ownership over time.

Common Applications Where PTFE Excels

The unique properties of PTFE make it the go-to solution in several demanding industries.

Oil & Gas

In this sector, seals are exposed to abrasive media, high pressures, and aggressive chemicals. PTFE's durability and chemical inertness ensure reliable performance and prevent environmental contamination.

Aerospace

Aerospace applications demand reliability under extreme temperatures and pressures. PTFE's low outgassing properties are also critical for use in vacuum or space environments.

Food & Beverage Processing

Virgin PTFE is FDA and USDA approved, making it safe for direct contact with consumables. Its ability to handle clean-in-place (CIP) chemicals and high temperatures without degrading is essential for hygienic operations.

Making the Right Choice for Your Application

Selecting the correct seal material depends entirely on your specific operational demands.

- If your primary focus is operating in extreme temperatures or with aggressive chemicals: PTFE is the superior choice due to its unmatched thermal stability and chemical inertness.

- If your primary focus is minimizing friction for high-speed or energy-efficient systems: The low coefficient of friction in PTFE will reduce shaft wear, heat generation, and power loss.

- If you are sealing a standard application with moderate temperatures and speeds: A traditional elastomer seal may provide a more cost-effective solution.

Ultimately, choosing a PTFE seal is an investment in long-term reliability for your most critical applications.

Summary Table:

| Advantage | Benefit |

|---|---|

| Extremely Low Friction | Reduces torque, heat, and energy consumption; extends equipment life. |

| Wide Temperature Range | Performs reliably from -200°C to +260°C. |

| Chemical Inertness | Resists nearly all industrial chemicals, preventing degradation. |

| High-Speed & Pressure Capability | Maintains stability in demanding applications like pumps and compressors. |

Solve your most challenging sealing problems with KINTEK PTFE components.

Our precision-manufactured PTFE seals, liners, and labware are engineered for the extreme demands of the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders to ensure a perfect fit for your application.

Invest in long-term reliability and enhanced performance. Contact KINTEK today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications