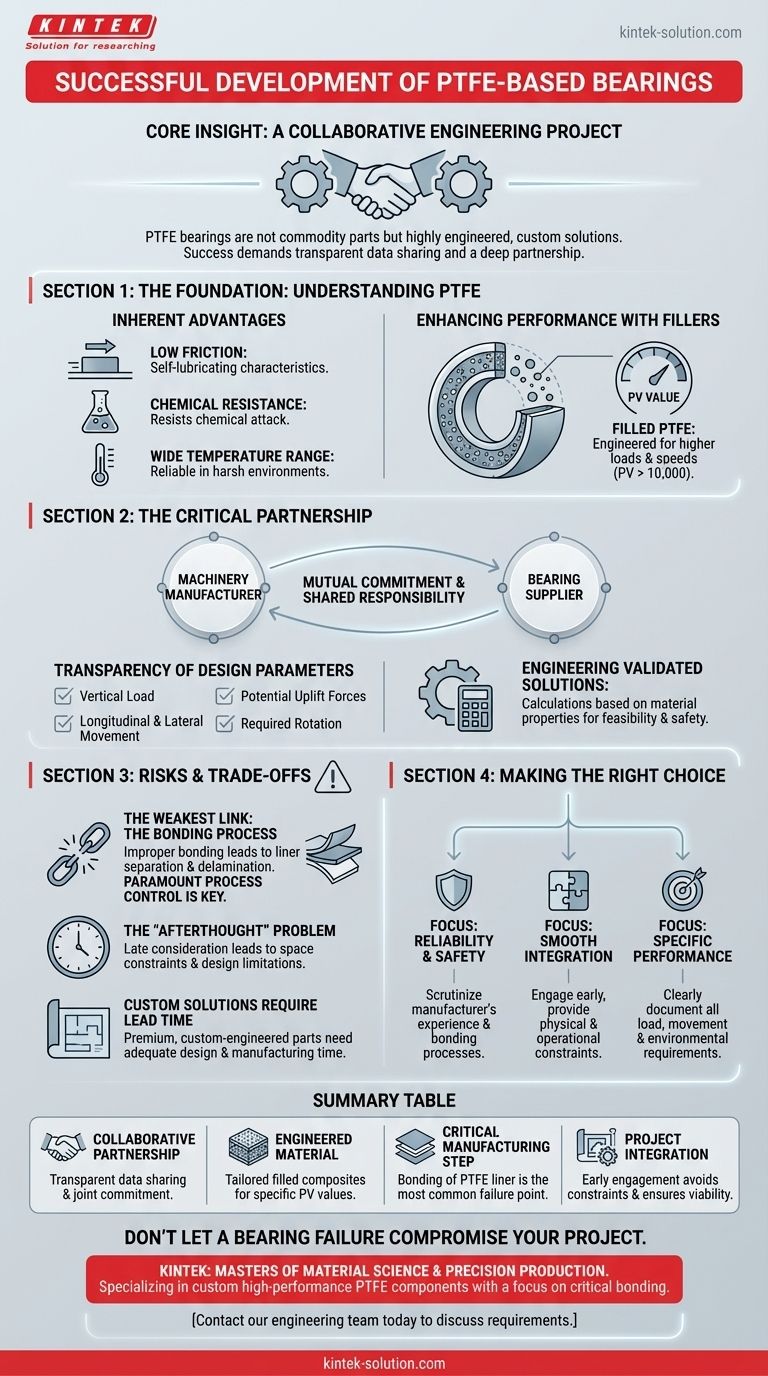

Successful development of PTFE-based bearings requires far more than specifying a material; it demands a dedicated partnership between the machinery manufacturer and the bearing supplier. This collaboration must be built on transparent data sharing and a deep understanding of the application's unique engineering challenges, from initial design through final implementation.

The core insight is that PTFE bearings are not commodity parts but highly engineered, custom solutions. Their success hinges on treating the entire process—from design specification to manufacturing—as a collaborative engineering project where expertise in material science and process control is paramount.

The Foundation: Understanding PTFE's Role

Polytetrafluoroethylene (PTFE) is selected for specific, demanding applications due to its unique combination of properties. Understanding these inherent advantages is the first step in its successful implementation.

Inherent Material Advantages

PTFE offers an exceptionally low coefficient of friction, which is the source of its self-lubricating characteristics. It is also highly resistant to chemical attack and can operate reliably across a wide temperature range, making it suitable for harsh environments.

Enhancing Performance with Fillers

For applications with higher loads and speeds, a material's PV value (Pressure-Velocity limit) is critical. While pure PTFE has limitations, filled PTFE composites can be engineered to handle significantly higher PV values, often exceeding 10,000, by incorporating additives that improve strength and wear resistance.

The Critical Partnership in Development

A successful outcome is almost entirely dependent on the quality of the relationship and communication between the end-user and the bearing manufacturer.

The Need for Mutual Commitment

Both machinery manufacturers and bearing suppliers must demonstrate a clear commitment to the project. This involves a shared responsibility for the bearing's performance within the larger system.

Transparency of Design Parameters

Clients must specify all critical design parameters upfront. This includes vertical load, longitudinal and lateral movement, potential uplift forces, and required rotation, which are essential for the manufacturer to design a viable solution.

Engineering Validated Solutions

The manufacturer is responsible for using these parameters to design the bearing. Crucially, they must provide supporting calculations based on material properties to verify the design's feasibility and safety before production.

Understanding the Trade-offs and Critical Risks

While PTFE bearings offer significant advantages, they also present unique challenges and failure points that must be managed carefully. Ignoring these risks can lead to rapid and catastrophic failure.

The Bonding Process: The Weakest Link

The single most critical manufacturing step is bonding the PTFE liner to its backing material. This process is notoriously difficult, and improper bonding can lead to liner separation and delamination under load, causing immediate failure of the bearing.

The "Afterthought" Problem

Bearings are often overlooked until the late stages of a project. This forces designers to work around significant constraints, such as limited space or restrictions on welding and bolting, which complicates the design and increases costs.

Custom Solutions Require Lead Time

Because of late-stage requirements and unique project constraints, most high-performance PTFE bearings are custom-engineered solutions, not off-the-shelf parts. This reality means they are premium products that require adequate lead time for proper design and manufacturing.

Making the Right Choice for Your Application

To ensure a successful outcome, your approach must align with your project's primary goal.

- If your primary focus is reliability and safety: Scrutinize the manufacturer's experience and quality control, paying special attention to their PTFE bonding processes.

- If your primary focus is smooth project integration: Engage with the bearing supplier early in the design phase and provide all known physical and operational constraints.

- If your primary focus is achieving specific performance metrics: Clearly document and communicate all load, movement, and environmental requirements to ensure the design is properly engineered and validated.

By treating the selection and development of PTFE bearings as a critical engineering discipline, you can successfully leverage their powerful properties for your application.

Summary Table:

| Key Success Factor | Description |

|---|---|

| Collaborative Partnership | Requires transparent data sharing and joint commitment between machinery maker and bearing supplier. |

| Engineered Material | PTFE is not a commodity; filled composites are tailored for specific PV values and harsh environments. |

| Critical Manufacturing Step | The bonding of the PTFE liner is the most common point of failure; process control is paramount. |

| Project Integration | Early engagement in the design phase is essential to avoid constraints and ensure a viable solution. |

Don't let a bearing failure compromise your project's reliability. The successful development of PTFE-based bearings hinges on a partnership with a manufacturer that masters both material science and precision production.

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom bearings, for the semiconductor, medical, laboratory, and industrial sectors. We treat every project as a collaborative engineering challenge, providing custom fabrication from prototypes to high-volume orders with a focus on the critical bonding process.

Contact our engineering team today to discuss your specific load, movement, and environmental requirements. Let's engineer a reliable solution together.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry