The low friction coefficient of a PTFE expansion bellow directly benefits fluid flow by minimizing pipeline resistance and preventing blockages from material buildup. This dual-action effect reduces the energy required to move fluids and ensures the system maintains its designed operational efficiency over time.

The low friction of PTFE is a critical feature, but its true value is realized when combined with its non-stick surface and chemical inertness. This synergy creates a highly reliable component that not only ensures smooth flow but also protects the entire system from contamination, corrosion, and operational downtime.

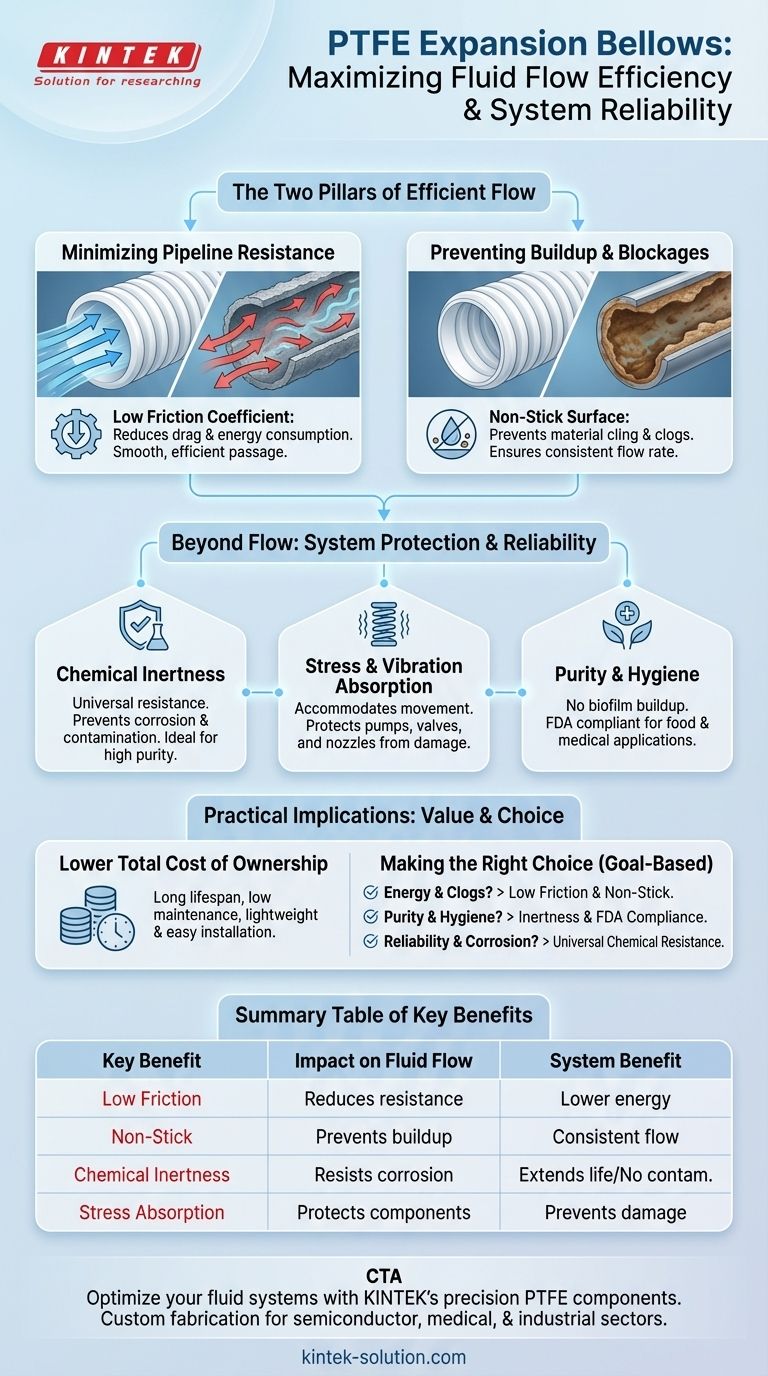

The Two Pillars of Efficient Flow

The benefit of PTFE's surface on fluid dynamics can be understood by examining two distinct but related properties: its low coefficient of friction and its non-adhesive nature.

Minimizing Pipeline Resistance

A low coefficient of friction means that fluids can pass over the bellow's surface with minimal drag. Think of it as the difference between sliding an object over sandpaper versus ice.

This reduction in resistance directly translates to lower energy consumption. Pumps and other machinery do not have to work as hard to maintain the required flow rate, leading to significant operational cost savings.

Preventing Buildup and Blockages

PTFE is famous for its non-stick, or non-adhesive, properties. This means materials, from viscous chemicals to particulates in a slurry, are far less likely to cling to the bellow's convoluted surfaces.

This characteristic is crucial for preventing deposit buildup over time. By keeping the internal pathway clear, PTFE bellows ensure a consistent flow rate, reduce the risk of blockages, and simplify system cleaning and maintenance.

Beyond Flow: How PTFE Protects the System

While improved flow is a key benefit, the properties of PTFE offer a cascade of advantages that contribute to the health and reliability of the entire fluid transport system.

Unmatched Chemical Inertness

PTFE offers universal chemical resistance, meaning it can withstand harsh and corrosive environments without degrading.

This ensures the bellow itself has a long lifespan and, just as importantly, prevents the bellow material from leaching into and contaminating the process fluid. This is non-negotiable in high-purity applications like semiconductor or pharmaceutical manufacturing.

Absorbing System Stress and Vibration

The primary purpose of any expansion bellow is to provide flexibility. PTFE bellows excel at accommodating axial, lateral, and angular movements.

This flexibility allows them to absorb vibrations from machinery and compensate for thermal expansion and contraction in the pipeline. By isolating these stresses, the bellow protects more rigid and expensive components like pumps, valves, and vessel nozzles from damage.

Ensuring Purity and Hygiene

The non-stick surface that prevents blockages also prevents the buildup of biofilms or other contaminants.

Combined with its suitability for sterilization and FDA compliance, this makes PTFE an ideal material for industries with high hygiene standards, such as food production and medical device manufacturing.

Understanding the Practical Implications

Selecting a component is always about balancing performance characteristics with system demands. PTFE's unique combination of properties makes it a powerful solution, but it's important to understand where it provides the most value.

Total Cost of Ownership

PTFE bellows are noted for being a cost-effective choice. This value extends beyond the initial purchase price.

The long lifespan, low maintenance requirements, and reduced need for specialized installation tools contribute to a lower total cost of ownership compared to materials that may require more frequent replacement or upkeep in demanding environments.

Lightweight and Easy Installation

The lightweight nature of PTFE makes installation significantly easier and faster than with heavy, rigid metal components.

This can reduce labor costs and installation time, allowing projects to be completed more efficiently and with less strain on personnel.

Making the Right Choice for Your System

To determine if PTFE bellows are the optimal solution, consider your primary engineering goal.

- If your primary focus is energy efficiency and preventing clogs: The combination of low friction and non-stick properties makes PTFE an ideal choice, especially for viscous fluids or slurries.

- If your primary focus is fluid purity and hygiene: PTFE's chemical inertness, non-adhesive surface, and FDA compliance provide unmatched advantages for food, pharmaceutical, or semiconductor applications.

- If your primary focus is system reliability in a corrosive environment: PTFE's universal chemical resistance ensures a long service life and protects system integrity where many metals would fail.

By understanding these interconnected properties, you can confidently specify a component that ensures both efficient flow and long-term system integrity.

Summary Table:

| Key Benefit | Impact on Fluid Flow System |

|---|---|

| Low Friction Coefficient | Reduces pipeline resistance, lowering energy consumption for pumps. |

| Non-Stick Surface | Prevents material buildup and blockages, ensuring consistent flow. |

| Chemical Inertness | Resists corrosion, prevents contamination, and extends component life. |

| Stress & Vibration Absorption | Protects pumps, valves, and nozzles from damage due to movement. |

Optimize your fluid systems with KINTEK's precision PTFE components.

Our PTFE expansion bellows, seals, liners, and custom labware are engineered to deliver the low friction, non-stick, and chemically inert properties critical for efficient and reliable operation. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Reduce energy costs, prevent downtime, and ensure system purity—contact our experts today to discuss your application needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What overall value do PTFE-free bushings provide? A Strategic Choice for Environmental & Mechanical Performance

- What are some specific uses of PTFE in chemical handling? Enhance Safety and Reliability in Your Process

- Which type of PTFE gasket is better for uneven surfaces or fragile flanges? Seal with Confidence Using ePTFE

- What industries commonly use PTFE and nylon bushings and thrust washers? Select the Right Material for Your Application

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance

- Can PTFE machined parts be customized according to specific requirements? Achieve Precision for Demanding Applications

- What causes a PTFE butterfly valve to leak? Diagnose and Prevent Seal Failure

- What materials can PTFE O-rings be produced with? From Virgin PTFE to Enhanced Compounds