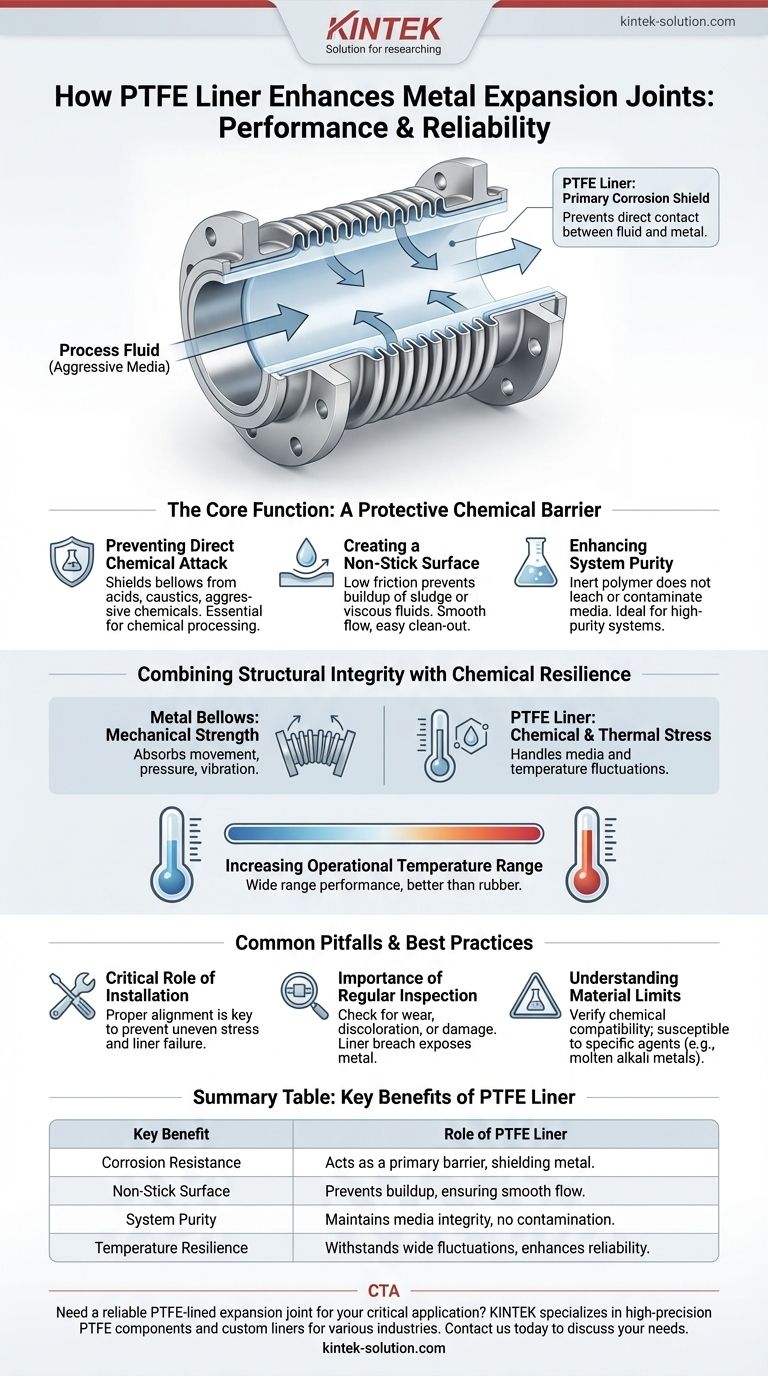

In a metal expansion joint, a PTFE liner acts as a primary corrosion shield. This specialized liner prevents the process fluid from ever touching the flexible metal convolutions (bellows) of the joint. By isolating the structural metal from potentially corrosive media, the PTFE component dramatically enhances the joint's durability and reliability in demanding applications.

While metal expansion joints offer the mechanical strength needed to absorb movement and pressure, their core vulnerability is chemical corrosion. A PTFE liner solves this by combining the robust structure of metal with the near-universal chemical inertness of PTFE, creating a superior composite solution for aggressive service environments.

The Core Function: A Protective Chemical Barrier

The primary contribution of PTFE is creating an inert barrier between the process media and the metal body of the expansion joint. This has several immediate performance benefits.

Preventing Direct Chemical Attack

The most critical function of the PTFE liner is to provide exceptional corrosion resistance. It acts as the primary wetted surface, effectively shielding the load-bearing metal bellows from acids, caustics, and other aggressive chemicals that would otherwise cause rapid degradation.

This protection is essential in industries like chemical processing, wastewater treatment, and pharmaceuticals, where media compatibility is a constant concern.

Creating a Non-Stick Surface

PTFE is famous for its low coefficient of friction, which creates a non-stick (hydrophobic) surface. In a piping system, this property prevents the buildup of viscous fluids, sludge, or other particulates on the interior of the expansion joint.

This ensures a smooth, consistent flow and simplifies system clean-out, which is particularly vital for food, beverage, and pharmaceutical applications where hygiene is paramount.

Enhancing System Purity

Because PTFE is an inert polymer, it does not leach or contaminate the process media. This makes PTFE-lined joints an ideal choice for high-purity systems.

The liner ensures that the material being transported remains free from metallic ions or other impurities that could be shed by the expansion joint's body.

Combining Structural Integrity with Chemical Resilience

A PTFE-lined metal expansion joint is a composite component, designed to leverage the best properties of both materials. It is not simply a metal joint with a coating, but a system where each part plays a distinct role.

The Best of Both Worlds

The metal bellows provide the mechanical strength and flexibility required to absorb thermal expansion, contraction, vibration, and pipe misalignment under high pressure and temperature.

Simultaneously, the PTFE liner handles the chemical and thermal stress from the media. This dual-material design creates a component that is far more capable than one made from either material alone.

Increasing Operational Temperature Range

PTFE maintains its integrity and chemical resistance across a very wide temperature range. This property allows PTFE-lined metal joints to be used in applications with significant temperature fluctuations where a standard rubber joint would fail.

Common Pitfalls and Best Practices

While highly effective, the performance of a PTFE-lined joint is dependent on proper handling and application. Understanding its limitations is key to ensuring a long service life.

The Critical Role of Installation

Proper pipe alignment is non-negotiable. Misalignment can create uneven stress on the PTFE liner, leading to folds, cracks, or premature failure at the point of contact with the metal bellows.

Always adhere strictly to the manufacturer's installation guidelines, paying close attention to torque specifications and alignment tolerances.

The Importance of Regular Inspection

The PTFE liner is the first line of defense. While the metal body provides secondary containment, any breach in the liner exposes the structural bellows to corrosion.

Regular inspections for signs of wear, discoloration, or damage are crucial, especially in high-pressure or highly corrosive environments.

Understanding Material Limits

While PTFE offers broad chemical resistance, it is not invincible. Certain materials, such as molten alkali metals and some powerful halogenated agents, can attack it. Always verify chemical compatibility for your specific application before specification.

Making the Right Choice for Your System

Selecting the correct expansion joint requires matching its capabilities to your primary operational goal.

- If your primary focus is handling highly corrosive chemicals: A PTFE-lined metal expansion joint is your most reliable option for protecting the structural integrity of the bellows.

- If your primary focus is maintaining product purity: The inert, non-stick surface of a PTFE liner is essential for preventing media contamination in pharmaceutical or food-grade systems.

- If your primary focus is managing high pressure and temperature: The composite structure leverages the mechanical strength of metal while the PTFE handles the harsh environmental conditions of the fluid.

By viewing the PTFE liner as an integral system component, you can confidently specify the right expansion joint to ensure both safety and long-term system integrity.

Summary Table:

| Key Benefit | Role of PTFE Liner |

|---|---|

| Corrosion Resistance | Acts as a primary barrier, shielding metal bellows from acids, caustics, and aggressive chemicals. |

| Non-Stick Surface | Prevents buildup of viscous fluids or particulates, ensuring smooth flow and easy cleaning. |

| System Purity | Maintains media integrity by preventing contamination from metallic ions or impurities. |

| Temperature Resilience | Withstands wide temperature fluctuations, enhancing joint reliability in varying conditions. |

Need a reliable PTFE-lined expansion joint for your critical application?

KINTEK specializes in manufacturing high-precision PTFE components, including custom liners for metal expansion joints used in semiconductor, medical, laboratory, and industrial settings. Our expertise ensures your system benefits from superior chemical resistance, durability, and purity.

Contact us today to discuss your custom fabrication needs—from prototypes to high-volume orders—and protect your operations with precision-engineered solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some industrial applications of PTFE seals? Solve Your Toughest Sealing Challenges

- How does a Labyrinth PTFE Seal work? Achieve Frictionless, Long-Term Reliability

- What material are PTFE envelope gaskets made from? A Guide to Their Composite Construction

- What should be placed between a shirt and a heat press? Protect Your Gear with the Right Barrier

- In which types of structures are PTFE bearing pads commonly used? Essential for Bridges, Buildings & Stadiums

- What are the main benefits of PTFE lined butterfly valves? Superior Performance for Corrosive & High-Purity Media

- What are the automotive applications of Teflon sheets? Enhance Efficiency, Reliability & Durability

- What are the overall benefits of PTFE spring energized seals for oil and gas operations? Achieve Unmatched Reliability in HPHT Environments