In short, Polytetrafluoroethylene (PTFE) bearing pads are used in massive civil engineering structures. You will find them at critical connection points in bridges, stadiums, and high-rise buildings where they are essential for managing immense forces and accommodating structural movement.

The core purpose of a PTFE bearing is to create a high-load capacity, low-friction sliding surface. This allows enormous structures to safely expand, contract, rotate, and absorb vibrations without generating destructive internal stress.

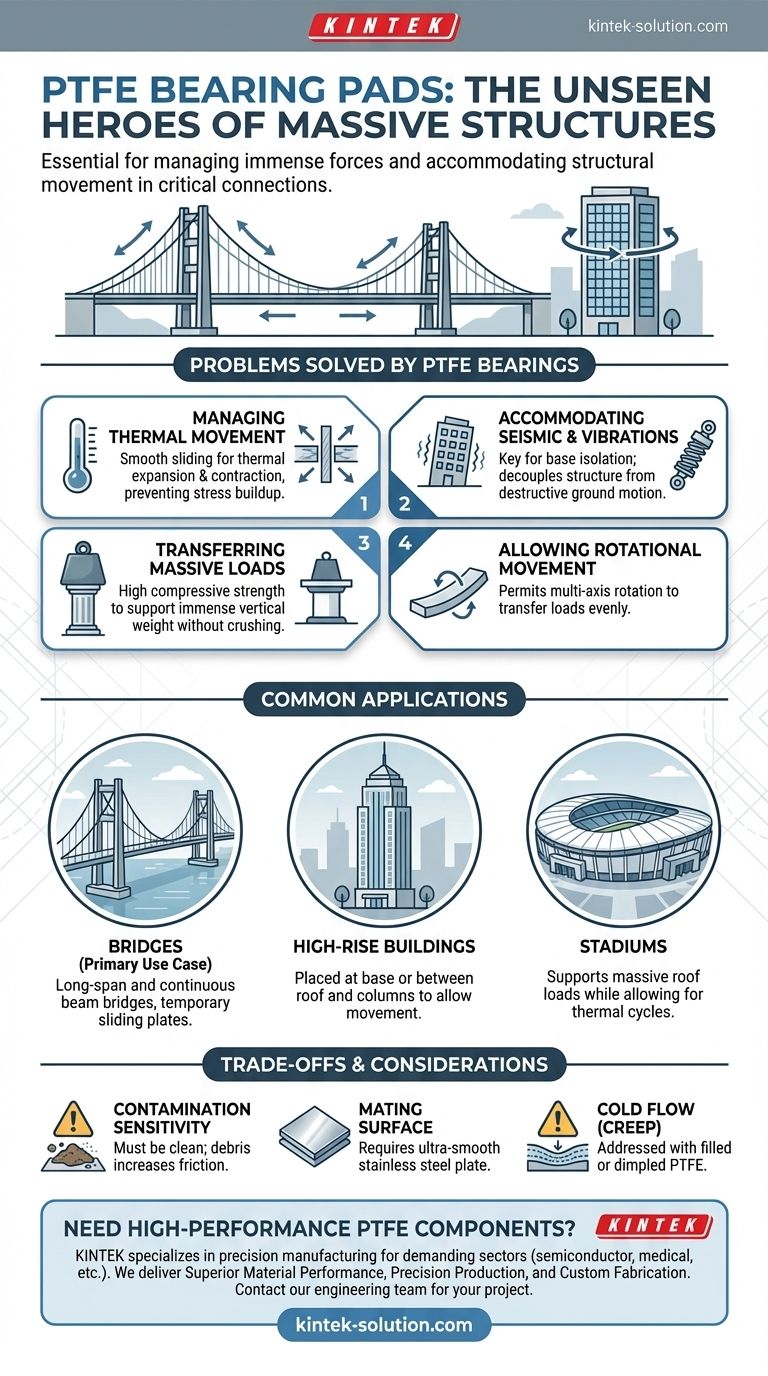

What Problem Do PTFE Bearings Solve?

Large structures are not static; they are constantly in motion. PTFE bearings are engineered components designed to safely manage this movement, which is primarily driven by three factors.

Managing Thermal Expansion and Contraction

All materials expand when heated and contract when cooled. Over the length of a bridge span or a large stadium roof, this movement can measure several inches.

PTFE's extremely low coefficient of friction (one of the lowest of any solid material) allows structural elements to slide past one another smoothly. This prevents the buildup of immense stress that could otherwise cause cracking and structural failure.

Accommodating Seismic Activity and Vibrations

In earthquake-prone regions, buildings and bridges must be able to move with the ground to dissipate energy.

PTFE bearings can be a key part of a base isolation system. They effectively decouple the superstructure from its foundation, allowing the ground to move underneath while the building remains more stable, protecting it and its occupants.

Transferring Massive Vertical Loads

Despite being a sliding surface, a PTFE bearing is designed to support the immense weight of the structure above it.

These pads have exceptional compressive strength, allowing them to transfer massive vertical loads from a beam or column into the pier or foundation below without being crushed.

Allowing for Rotational Movement

When a bridge beam deflects under the weight of traffic, its ends rotate slightly.

Many PTFE bearings are designed as part of an assembly (like a pot bearing or spherical bearing) that allows for this multi-axis rotation. This ensures loads are transferred evenly and prevents damage from bending forces.

Where You Will Find PTFE Bearings in Practice

While the principles are universal, the application of PTFE bearings is most common in specific large-scale construction scenarios.

Bridges (The Primary Use Case)

Bridges are the most common application for PTFE bearings. Their long, heavy spans are highly susceptible to thermal movement and deflection.

You will find them on large-span and multi-span continuous beam bridges. They are also used as temporary sliding plates during construction for methods like incremental launching, where bridge segments are pushed across piers.

High-Rise Buildings and Stadiums

The steel frames of skyscrapers and the massive roofs of stadiums also experience significant thermal movement.

PTFE bearings are often placed between the roof structure and its supporting columns or at the base of buildings. This allows the structure to move independently in response to temperature, wind sway, or seismic events.

Understanding the Trade-offs and Considerations

While highly effective, the performance of PTFE bearings depends on proper design and installation. Their primary strength—the low-friction surface—is also their primary vulnerability.

Sensitivity to Contamination

The low-friction properties of PTFE are only effective when the pad and its mating surface are perfectly clean.

Dirt, grit, or construction debris can become embedded in the soft PTFE, dramatically increasing friction and potentially scoring the opposing surface. This is why they are always installed with robust sealing systems.

Mating Surface Requirements

A PTFE pad does not slide against concrete or rough steel. It requires a hard, ultra-smooth counter-surface to achieve its low friction.

This is almost always a highly polished stainless steel plate. The quality and finish of this plate are just as critical to the bearing's function as the PTFE itself.

Potential for "Cold Flow" or Creep

Under very high, sustained loads, PTFE can slowly deform over time—a phenomenon known as creep or "cold flow."

Engineers account for this by using filled or dimpled PTFE. The PTFE is either reinforced with materials like glass fiber or confined within a steel plate with small dimples, which prevents it from squeezing out under pressure.

Making the Right Choice for Your Goal

The decision to use PTFE bearings is driven by the need to manage movement and load in large structures.

- If your primary focus is managing thermal movement in a long-span bridge: PTFE sliding bearings are the industry-standard solution for allowing controlled expansion and contraction.

- If your primary focus is seismic protection for a major building: These bearings are a critical component of base isolation systems that decouple the structure from destructive ground motion.

- If your primary focus is supporting a heavy, wide-roof structure: PTFE pads provide the necessary load-bearing capacity while accommodating movement from wind, thermal cycles, and imposed loads.

Ultimately, these simple pads are fundamental components that make the design and long-term survival of our largest and most ambitious structures possible.

Summary Table:

| Structure Type | Primary Function of PTFE Bearing Pad |

|---|---|

| Bridges | Manage thermal expansion/contraction of long spans. |

| High-Rise Buildings | Accommodate movement from wind, thermal cycles, and sway. |

| Stadiums | Support massive roof loads while allowing for movement. |

| Seismic Structures | Act as part of base isolation systems to dissipate energy. |

Need High-Performance PTFE Components for Your Critical Applications?

KINTEK specializes in the precision manufacturing of PTFE components, including custom bearing pads, seals, and liners. Our expertise supports the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors.

We deliver:

- Superior Material Performance: Engineered PTFE for low friction, high load capacity, and chemical resistance.

- Precision Production: Components manufactured to exacting specifications for reliable performance.

- Custom Fabrication: From initial prototypes to high-volume production runs.

Let us be your trusted partner for PTFE solutions. Contact our engineering team today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability