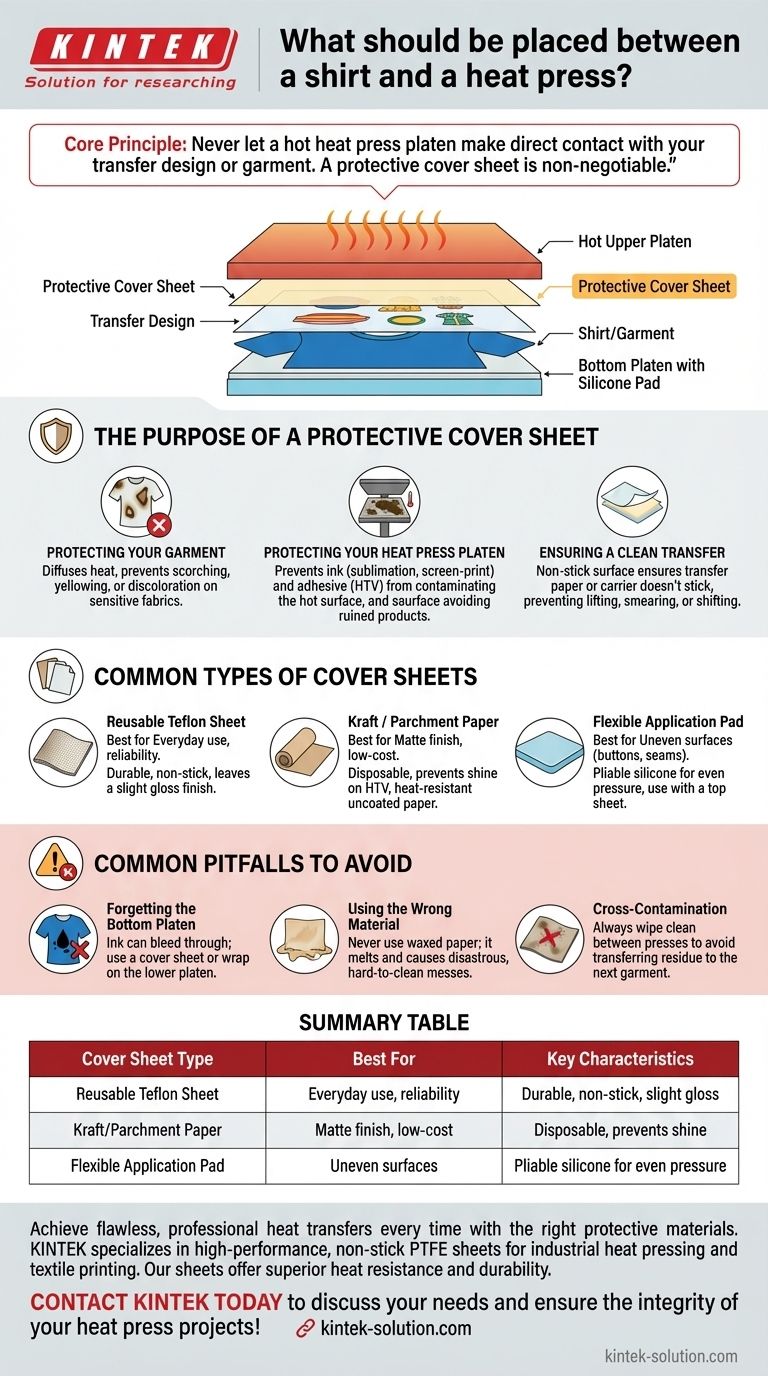

To protect both your garment and your equipment, you must place a protective, non-stick cover sheet between the shirt and the hot upper platen of the heat press. The industry standard for this is a reusable Teflon sheet, which acts as a critical barrier to prevent scorching the fabric and keeps ink or adhesive residue from contaminating your press.

The core principle is simple: never let a hot heat press platen make direct contact with your transfer design or garment. A protective cover sheet is a non-negotiable tool that ensures the integrity of your project and the longevity of your equipment.

The Purpose of a Protective Cover Sheet

Using a cover sheet is a fundamental step for achieving professional, consistent results. It serves three distinct but equally important functions during the heat transfer process.

Protecting Your Garment

The intense, direct heat from a press platen can easily damage fabric. A cover sheet diffuses the heat slightly, preventing scorching or burning, especially on sensitive materials like polyester or blends.

For white or light-colored garments, it also prevents the common issue of yellowing or discoloration that can occur from direct contact with the hot metal.

Protecting Your Heat Press Platen

This is arguably the most critical function for your business. Inks from sublimation or screen-printed transfers, as well as excess adhesive from heat transfer vinyl (HTV), can transfer onto the hot platen.

Without a protective sheet, this residue will bake onto the platen's coating. This contamination will then transfer to every subsequent shirt you press, ruining your products and potentially damaging the platen itself.

Ensuring a Clean Transfer

The non-stick surface of a Teflon sheet ensures that the transfer paper or vinyl carrier sheet does not stick to the platen. This allows you to open the press cleanly without the risk of the design lifting, smearing, or being pulled out of place.

Common Types of Cover Sheets

While Teflon is the standard, different sheets can be used to achieve slightly different results.

Reusable Teflon Sheet

This is the most common and durable option. It's a woven fiberglass fabric coated with PTFE (Teflon). It can be used hundreds of times and is easily wiped clean if any residue gets on it. It typically leaves a standard, slightly glossy finish on HTV.

Kraft Paper or Parchment Paper

These are excellent, low-cost disposable alternatives. Use uncoated kraft paper or silicone-treated parchment paper (like you'd use for baking).

These sheets are often preferred when you want to achieve a matte finish on heat transfer vinyl, as they don't impart the same shine as a Teflon sheet.

Flexible Application Pad

This is a silicone rubber sheet that is thicker and more pliable than a Teflon sheet. Its primary use is to ensure even pressure when pressing over challenging items like buttons, zippers, or heavy seams. It is still recommended to use a standard Teflon or paper sheet over the top.

Common Pitfalls to Avoid

Even with a cover sheet, mistakes can happen. Being aware of them is key to preventing ruined garments.

Forgetting the Bottom Platen

Ink, especially from sublimation, can bleed through the back of a garment. Always protect your lower platen's silicone pad by either sliding a cover sheet inside the shirt or using a permanent Teflon wrap on the bottom platen.

Using the Wrong Material

Never use waxed butcher paper or any other material not rated for high temperatures. The wax or coatings can melt onto your garment and platen, creating a disastrous mess that is nearly impossible to clean.

Cross-Contamination

Always wipe your Teflon sheet clean between presses. A small amount of ink residue from a previous job can easily transfer to the next, ruining a perfectly good garment.

Making the Right Choice for Your Goal

Your choice of cover sheet should align with your project's specific needs.

- If your primary focus is reliability and long-term use: A reusable Teflon sheet is the most cost-effective and dependable choice for everyday operations.

- If your primary focus is achieving a matte finish on vinyl: Use a sheet of uncoated kraft paper or parchment paper for the final press.

- If your primary focus is pressing over uneven surfaces like seams: Place a flexible pad or pressing pillow inside the shirt and use your standard Teflon sheet on top.

Consistently using the correct protective sheet is the simplest step to guarantee professional results and protect your investment.

Summary Table:

| Cover Sheet Type | Best For | Key Characteristics |

|---|---|---|

| Reusable Teflon Sheet | Everyday use, reliability | Durable, non-stick, leaves a slight gloss |

| Kraft/Parchment Paper | Matte finish, low-cost | Disposable, prevents shine on HTV |

| Flexible Application Pad | Uneven surfaces (buttons, seams) | Pliable silicone for even pressure |

Achieve flawless, professional heat transfers every time with the right protective materials. KINTEK specializes in manufacturing high-performance, non-stick PTFE (Teflon) sheets and components designed for the demanding environments of industrial heat pressing, textile printing, and more. Our precision-engineered sheets offer superior heat resistance and durability, protecting both your garments and your valuable equipment from scorching and contamination.

Whether you need a standard reusable sheet or a custom solution for your specific press, our team is ready to help—from prototype to high-volume orders. Contact KINTEK today to discuss your needs and ensure the integrity of your heat press projects!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How do PTFE gaskets perform under long-term operation and cyclic loads? Ensure Reliable Sealing in Demanding Applications

- What is the chemical resistance of Virgin PTFE? Unmatched Inertness for Harsh Chemical Environments

- Can machined PTFE parts be customized? Achieve Precision Solutions for Demanding Applications

- What makes PTFE rotary shaft seals suitable for low friction or dry running applications? Unlock High-Speed, Dry-Running Performance

- How does PTFE differ from other sealing materials like elastomers or polyurethane? A Guide to Extreme Performance Seals

- What are the two types of PTFE rods and their general applications? Choose the Right PTFE for Your Project

- What are the key properties of PTFE bellows? Unmatched Resilience for Demanding Environments

- What are important considerations when drilling PTFE? Achieve Clean, Accurate Holes in Soft Polymers