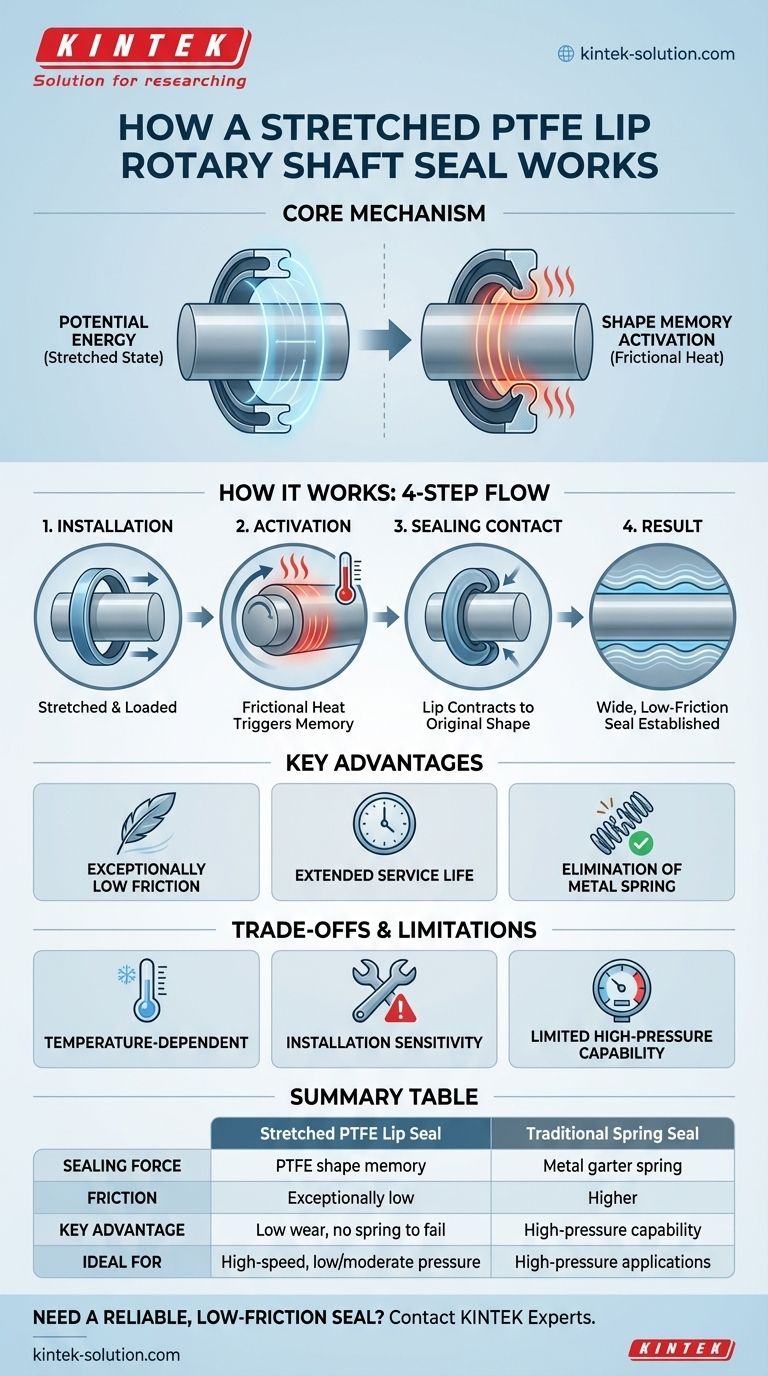

At its core, a Stretched PTFE Lip Rotary Shaft Seal functions by using the material's own "shape memory" to create a sealing force. Instead of relying on a traditional metal garter spring, the seal is installed in a stretched state. The friction from the rotating shaft generates just enough heat to activate the PTFE's memory, causing the sealing lip to attempt to shrink back to its original, smaller size and create a secure, low-friction seal.

The critical takeaway is that this seal design replaces mechanical spring force with the stored potential energy of the PTFE material itself. This shift results in a fundamentally different sealing mechanism characterized by a wide, low-pressure contact area, leading to significantly lower friction and wear.

The Core Mechanism: From Potential Energy to Sealing Force

To understand this seal, you must think of the material itself as the engine that powers the seal. The process is elegant and relies entirely on the unique properties of Polytetrafluoroethylene (PTFE).

The Role of PTFE's Shape Memory

PTFE, the material used for the lip, possesses a thermal shape memory. This means it "remembers" its original molded dimensions and will try to return to that shape when a specific activation temperature is reached.

The "Stretching" and Installation

During manufacturing and installation, the seal's inner diameter is made slightly smaller than the shaft it will seal. It is then carefully stretched to fit over the shaft, which effectively "loads" the seal lip with potential energy, much like a drawn bowstring.

Activation Through Frictional Heat

When the shaft begins to rotate, the initial light contact between the seal lip and the shaft generates a small amount of frictional heat. This minor increase in temperature is all that's needed to activate the PTFE's shape memory.

Creating the Sealing Contact

As the material's memory is triggered, the seal lip begins to contract, attempting to return to its original, smaller diameter. This action creates a consistent, wide, and uniform contact band against the shaft, establishing an effective and stable seal without the high-point loading of a metal spring.

Key Advantages of the Stretched Lip Design

This springless design philosophy offers distinct advantages that make it the optimal choice for specific applications, particularly those where friction is a primary concern.

Exceptionally Low Friction

By eliminating the high radial force of a metal spring and distributing the sealing load over a wider area, these seals generate significantly less friction. This reduces torque requirements and parasitic energy loss in the system.

Extended Service Life and Reliability

Lower friction directly translates to less wear on both the seal lip and the shaft surface. This reduction in wear extends the operational life of the seal and minimizes the need for costly maintenance and downtime.

Elimination of the Metallic Spring

Removing the metal spring component eliminates a potential point of failure. There is no risk of spring fatigue, breakage, or corrosion, which is a critical benefit in chemically aggressive or sanitary environments.

Understanding the Trade-offs and Limitations

While highly effective, this technology is not a universal solution. Its unique mechanism comes with specific operational considerations that must be respected for successful implementation.

Temperature-Dependent Activation

The seal's effectiveness relies on reaching an activation temperature. In extremely cold start-up scenarios, the seal may not perform optimally until the system generates enough initial friction and heat.

Installation Sensitivity

Proper installation is absolutely critical. The seal must be stretched correctly onto the shaft to ensure the right amount of potential energy is stored in the lip. Mishandling or improper sizing can compromise the seal's ability to function.

Limited High-Pressure Capability

The sealing force generated by material memory is inherently lower than what can be achieved with a high-tension metal spring. Therefore, stretched PTFE lip seals are typically best suited for low to moderate-pressure applications.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its core strengths to your primary operational goal.

- If your primary focus is minimizing friction and energy loss: The Stretched PTFE Lip Seal is an ideal choice, especially in high-speed applications where heat generation is a major concern.

- If your primary focus is maximizing reliability and service life: The springless design eliminates a common failure point and reduces wear, making it excellent for critical equipment where maintenance is difficult or costly.

- If your primary focus is sealing high internal pressures: You should consider an alternative, such as a spring-energized PTFE seal, which is specifically designed to provide the high radial load needed for demanding pressure conditions.

Ultimately, understanding this seal's reliance on thermal shape memory empowers you to deploy it where its unique, low-friction characteristics will provide the greatest value.

Summary Table:

| Feature | Stretched PTFE Lip Seal | Traditional Spring Seal |

|---|---|---|

| Sealing Force | PTFE shape memory (thermal activation) | Metal garter spring |

| Friction | Exceptionally low | Higher |

| Key Advantage | Low wear, energy efficiency, no spring to fail | High-pressure capability |

| Ideal For | High-speed, low-to-moderate pressure, critical reliability | High-pressure applications |

Need a reliable, low-friction seal for your critical equipment?

KINTEK specializes in manufacturing high-performance, custom PTFE components like stretched lip seals for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures optimal sealing force and extended service life for your applications.

Contact our experts today to discuss your custom fabrication needs, from prototypes to high-volume orders.

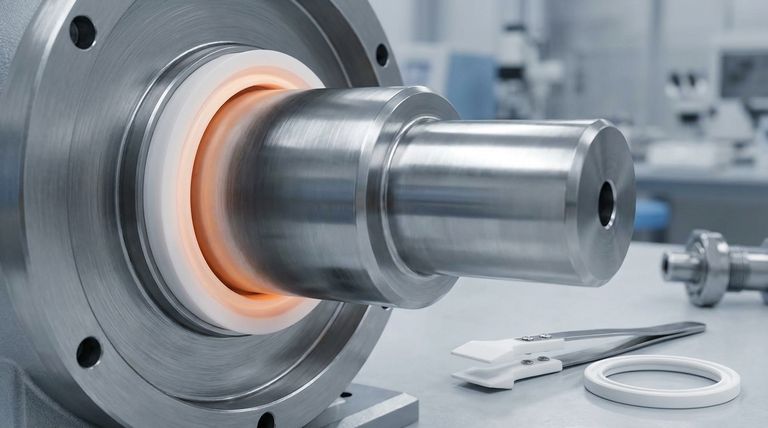

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What secondary manufacturing processes might PTFE parts require? Achieve Precise Specifications with Expert Machining

- What are the key properties of Teflon (PTFE) used in custom parts? | Achieve Peak Performance

- Where are PTFE valve seat rings commonly used? Ensuring Purity and Reliability in Critical Processes

- Why is PTFE popular in the oil and gas industry? Withstand Extreme Heat, Pressure & Corrosion

- What are the advantages of using PTFE for spring-energized seal jackets? Superior Performance in Extreme Conditions

- How should one choose between PEEK and PTFE backup rings? A Guide to Maximizing Seal Performance

- What are the limitations of PTFE O-rings' media resistance? Avoid Common Application Traps

- What standards are referenced for PTFE O-rings? Ensure Interchangeability & Superior Performance