The choice between PEEK and PTFE backup rings is a direct function of your application's operating pressure, temperature, and chemical environment. PEEK (Polyetheretherketone) is the definitive choice for high-pressure, high-temperature systems where mechanical strength is paramount. In contrast, PTFE (Polytetrafluoroethylene) excels in applications demanding broad chemical resistance, low friction, or performance at cryogenic temperatures.

A backup ring's sole purpose is to prevent O-ring extrusion under pressure. Therefore, the decision between PEEK and PTFE is a trade-off between PEEK's superior structural rigidity against high pressure and PTFE's unmatched chemical inertness and low-friction properties.

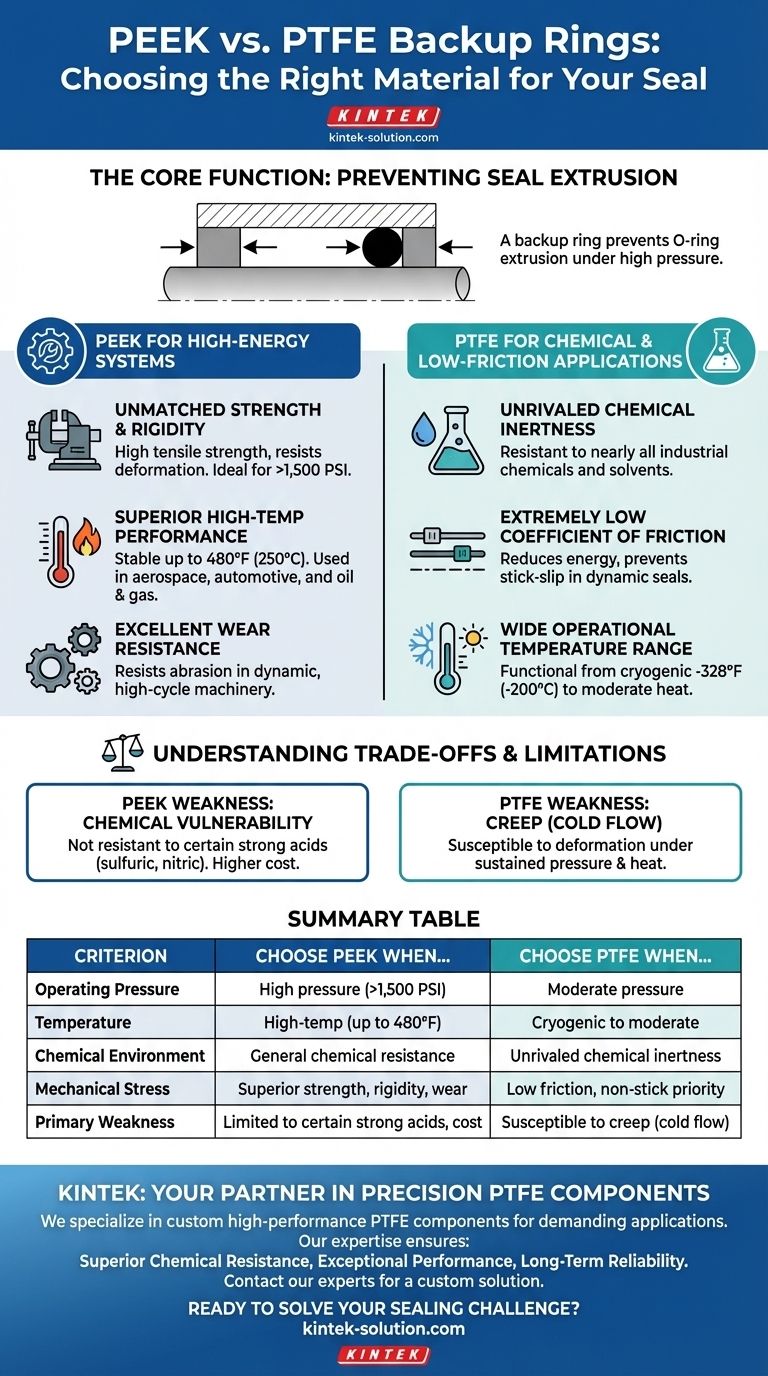

The Core Function: Preventing Seal Extrusion

Before comparing materials, it's critical to understand the role of a backup ring. In a high-pressure sealing application, the O-ring is forced against the low-pressure side of the gland.

If the gap between the moving and stationary hardware (the "extrusion gap") is too large, the pressure can force, or extrude, the O-ring material into this gap. This damages the O-ring, leading to leakage and eventual seal failure. A backup ring is a rigid, strong ring installed on the low-pressure side of the O-ring to physically block this gap and prevent extrusion.

Evaluating PEEK for High-Energy Systems

PEEK is an advanced semi-crystalline thermoplastic known for its exceptional mechanical properties. It is the material of choice when the primary challenge is managing extreme physical forces.

Unmatched Strength and Rigidity

PEEK has a very high tensile strength and stiffness. This rigidity means it will not deform or flow under intense pressure, providing a robust barrier that reliably supports the O-ring. This makes it ideal for hydraulic systems and high-pressure valves operating above 1,500 PSI (10.3 MPa).

Superior High-Temperature Performance

PEEK maintains its strength and dimensional stability at continuous service temperatures up to 480°F (250°C). This makes it essential for applications in aerospace, automotive engines, and downhole oil and gas equipment where high temperatures are common.

Excellent Wear Resistance

In dynamic applications where a shaft or piston is moving, PEEK exhibits outstanding resistance to wear and abrasion. This ensures a long service life in high-cycle machinery.

Leveraging PTFE for Chemical and Low-Friction Applications

PTFE is a fluoropolymer famous for its non-stick properties and chemical inertness. It is the default choice when the environment, not just the pressure, is the main concern.

Unrivaled Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This makes it the only viable option for sealing systems in the chemical processing industry or any application involving aggressive media that would degrade other polymers.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. In dynamic seals, this reduces the energy required for movement (breakout friction) and prevents the jerky "stick-slip" motion that can cause vibration and wear.

Wide Operational Temperature Range

While PEEK excels at high temperatures, PTFE's advantage is its incredible range. It remains flexible and functional in cryogenic applications down to -328°F (-200°C), where materials like PEEK would become brittle.

Understanding the Trade-offs and Limitations

An objective choice requires understanding where each material falls short. Choosing the wrong one can lead to premature failure.

PEEK's Primary Weakness

PEEK's main limitation is its lack of resistance to certain aggressive chemicals, such as concentrated sulfuric and nitric acids. While its chemical resistance is generally very good, it is not as universally inert as PTFE. It is also a more expensive material.

PTFE's Primary Weakness: Creep

PTFE's most significant drawback is its susceptibility to creep, also known as cold flow. Under sustained pressure and elevated temperature, PTFE can slowly deform and flow into the extrusion gap itself, compromising its function as a backup ring. This is why virgin PTFE is generally not recommended for very high-pressure static applications where PEEK is a better fit.

Making the Right Choice for Your Application

Use your system's most demanding requirement as the deciding factor.

- If your primary focus is extreme pressure (>1,500 PSI) and high temperature: Choose PEEK for its superior strength and resistance to extrusion and creep.

- If your primary focus is chemical compatibility or low friction: Select PTFE for its near-universal inertness and exceptionally low surface friction.

- If your primary focus is a dynamic, high-cycle application: PEEK is often preferred for its wear resistance, but evaluate PTFE if minimizing friction is the dominant concern.

- If your primary focus is a low-temperature or cryogenic environment: PTFE is the only suitable choice between the two materials.

By matching the material's core strength to your system's greatest challenge, you ensure optimal seal performance and reliability.

Summary Table:

| Criterion | Choose PEEK When... | Choose PTFE When... |

|---|---|---|

| Operating Pressure | High pressure (>1,500 PSI / 10.3 MPa) is the primary concern. | Pressure is moderate; chemical resistance or low friction is key. |

| Temperature | High-temperature applications (up to 480°F / 250°C). | Cryogenic to moderate temperatures, especially below -328°F / -200°C. |

| Chemical Environment | Good general chemical resistance is sufficient. | Unrivaled chemical inertness is required for aggressive media. |

| Mechanical Stress | Superior strength, rigidity, and wear resistance are needed. | Low friction and non-stick properties are the priority. |

| Primary Weakness | Limited resistance to certain strong acids; higher cost. | Susceptible to creep (cold flow) under sustained high pressure/heat. |

Ensure Optimal Seal Performance with Precision-Engineered PTFE Components

Selecting the right backup ring material is critical to preventing O-ring failure. At KINTEK, we specialize in the custom fabrication of high-performance PTFE components, including seals, liners, and labware, for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We understand the precise trade-offs between materials like PEEK and PTFE. Our expertise ensures you get a component that delivers:

- Superior Chemical Resistance: Withstand aggressive media.

- Exceptional Performance: From cryogenic temperatures to high-pressure environments.

- Long-Term Reliability: Precision-manufactured to prevent extrusion and extend seal life.

Whether you need a custom prototype or a high-volume order, we prioritize precision production to meet your exact specifications.

Ready to solve your sealing challenge? Contact our experts today to discuss your application and receive a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What industries commonly use PTFE lined dual plate check valves? Essential for Corrosive & High-Purity Applications

- Why is the non-reactivity of PTFE fasteners important in medical devices? Ensuring Patient Safety and Device Integrity

- How do PTFE gaskets contribute to electrical insulation? Ensuring Reliability in Harsh Environments

- What does it mean for Teflon coatings to be non-wetting? Unlock Superior Non-Stick & Chemical Resistance

- What industries use PTFE piston rings? Key Applications for Oil-Free & Corrosive Environments

- Why is UV resistance important for PTFE Teflon washers? Ensure Long-Term Reliability in Outdoor and Harsh Environments

- What medical applications benefit from PTFE's biocompatibility? Ensuring Patient Safety in Critical Devices

- What are the common applications of PTFE in industrial components? Seals, Bearings & More