At their core, Teflon bellow mechanical seals are a critical component for environmental protection in pulp and paper mills because they prevent the leakage of contaminated water and harsh process chemicals. Their unique material properties and flexible design create a highly reliable barrier in pumps, mixers, and wastewater systems, directly stopping pollutants from escaping into the environment and helping mills meet stringent regulatory standards.

The central challenge in a pulp and paper mill is containing aggressive and abrasive substances. Teflon bellow mechanical seals solve this not just by blocking leaks, but by being fundamentally immune to the chemical attacks and physical stresses that cause other types of seals to fail.

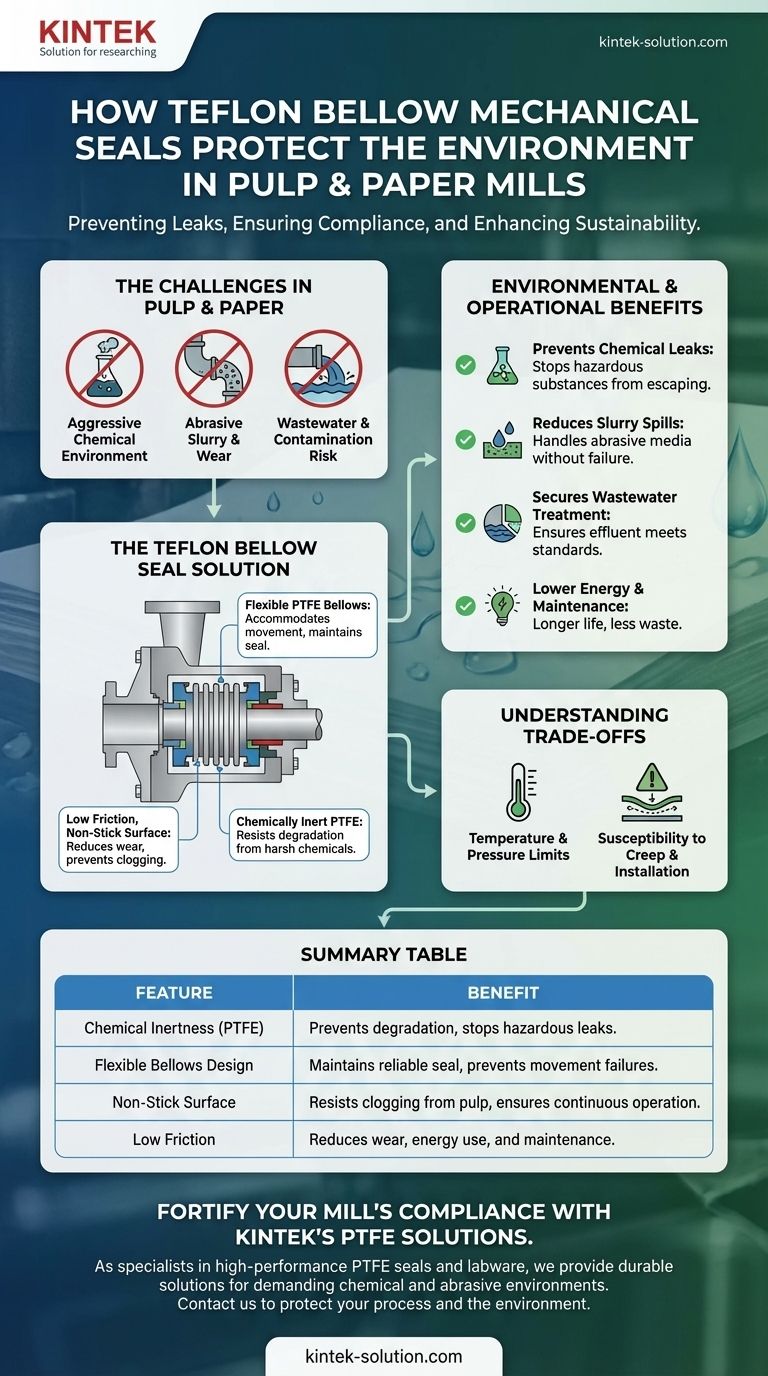

Why Sealing is a Critical Environmental Challenge

Pulp and paper manufacturing is an inherently demanding process. The conversion of wood into paper requires aggressive chemicals, high temperatures, and the movement of abrasive slurries, all of which pose significant risks to sealing systems.

The Aggressive Chemical Environment

Pulping and bleaching processes rely on a cocktail of harsh chemicals. A seal failure in a pump or agitator can lead to the release of these corrosive and environmentally harmful substances.

The Problem of Abrasive Slurries

Pulp slurry is abrasive and can quickly wear down standard seal faces. This wear and tear is a common cause of seal failure, leading to leaks that compromise both the process and environmental safety.

The Risk of Wastewater Leaks

Wastewater treatment is the final line of defense before water is discharged. A seal failure in this part of the plant could release untreated or partially treated effluent, causing direct environmental contamination and leading to significant regulatory penalties.

How Teflon Bellow Seals Provide a Robust Solution

The design and material of Teflon (PTFE) bellow seals directly counter the challenges found in pulp and paper mills. They are not just a component; they are a purpose-built solution for hostile environments.

Unmatched Chemical Resistance

PTFE is chemically inert, meaning it does not react with the vast majority of chemicals used in the mill. This is its single most important feature, as it ensures the seal will not degrade, swell, or weaken when exposed to corrosive fluids.

Flexible Bellows Accommodate Movement

The "bellow" design provides axial flexibility. This allows the seal to maintain constant face pressure even when there is shaft misalignment or radial movement, which is common in heavy industrial equipment. This flexibility ensures a consistent, reliable seal under dynamic conditions.

Non-Stick Surface Prevents Clogging

The famous non-stick quality of Teflon prevents sticky pulp and other viscous materials from building up on the seal components. This self-cleaning characteristic is vital for preventing clogs that could otherwise force the seal faces apart and cause a leak.

Low Friction Reduces Wear and Energy Use

PTFE has an extremely low coefficient of friction. This means the seal faces can rotate against each other with minimal resistance, which reduces operational energy loss and, more importantly, dramatically slows down wear. A longer-lasting seal means fewer failures and less maintenance over time.

Understanding the Trade-offs

While highly effective, Teflon bellow seals are not a universal solution. Understanding their limitations is key to proper application and avoiding failure.

Temperature and Pressure Boundaries

Standard PTFE has upper temperature and pressure limits that are generally lower than metal bellow seals. For extremely high-temperature applications, such as certain steam lines, an alternative material or design may be necessary.

Susceptibility to Creep

Under sustained high pressure and temperature, PTFE can be susceptible to "creep," a slow deformation of the material. This must be accounted for in the design and selection process for high-duty applications to ensure long-term sealing integrity.

Importance of Proper Installation

No seal can perform well if installed improperly. The flexibility of a bellow seal can sometimes mask installation errors, but a precise and clean installation is critical to prevent premature failure and ensure reliable environmental protection.

Making the Right Choice for Your Mill

Selecting the right seal is a balance between performance requirements, operational goals, and environmental responsibility.

- If your primary focus is regulatory compliance and environmental safety: Teflon bellow seals are the superior choice for handling corrosive chemicals and contaminated wastewater, providing the most reliable barrier against hazardous leaks.

- If your primary focus is reducing operational costs: The durability, low friction, and minimal maintenance needs of these seals lead to less downtime, lower energy consumption, and a longer service life.

- If your primary focus is process reliability with abrasive media: The flexible, non-clogging design ensures consistent performance where rigid or sticky-prone seals would quickly fail.

Ultimately, integrating Teflon bellow mechanical seals is a strategic decision that fortifies your plant's environmental stewardship and enhances its operational resilience.

Summary Table:

| Feature | Environmental & Operational Benefit |

|---|---|

| Chemical Inertness (PTFE) | Prevents seal degradation from corrosive pulping/bleaching chemicals, stopping hazardous leaks. |

| Flexible Bellows Design | Maintains a reliable seal despite shaft movement, preventing failures that lead to spills. |

| Non-Stick Surface | Resists clogging from pulp slurries, ensuring continuous operation and leak prevention. |

| Low Friction | Reduces wear for longer seal life and less maintenance, minimizing failure risk and waste. |

Fortify your mill's environmental compliance and operational reliability with KINTEK's precision PTFE components.

As specialists in manufacturing high-performance PTFE seals, liners, and labware for demanding industries like pulp and paper, we understand the critical need for leak-free operation. Our custom fabrication services, from prototypes to high-volume orders, ensure you get a seal perfectly suited to handle your specific chemical and abrasive challenges.

Contact KINTEK today to discuss how our durable PTFE solutions can protect your process and the environment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the disadvantages of PTFE gaskets? Key Limitations to Consider

- What are the main benefits of PTFE-lined bearings? Achieve Maintenance-Free, High-Performance Motion

- What are the common characteristics of PTFE and Graphite packing materials? Key Similarities and Critical Differences

- What types of industries and applications utilize PTFE parts? Discover the Versatility of PTFE

- What issue is associated with the leakage rate of PTFE ring gaskets? Overcoming Inherent Sealing Challenges

- What industries commonly use PTFE bellows and diaphragms, and why? Ensure Purity & Chemical Resistance

- How is the coefficient of friction for PTFE measured? A Guide to Precise Friction Data

- What lubrication benefits do PTFE bushes provide? Achieve Maintenance-Free, Low-Friction Performance